cable hot set testing factory

The Importance of Cable Hot Set Testing in Modern Manufacturing

In today's fast-paced technological landscape, ensuring the reliability and performance of electrical components is vital for the safety and efficiency of various applications. One essential process in this regard is cable hot set testing, a method used to evaluate the quality and durability of insulated cables under elevated temperatures. This article delves into the significance of cable hot set testing in manufacturing, particularly in factories specializing in cable production.

The Importance of Cable Hot Set Testing in Modern Manufacturing

Moreover, cable hot set testing is instrumental in complying with industry standards and regulations. Various international, national, and local standards outline the performance criteria that cables must meet to ensure electrical safety and reliability. Manufacturers often face rigorous scrutiny regarding their products' compliance with these standards. Implementing a robust hot set testing procedure not only ensures that the cables meet these regulations but also boosts manufacturers' reputations as reliable and quality-conscious suppliers. Such reputational benefit can facilitate access to more significant contracts and collaborations, enhancing the overall business landscape.

cable hot set testing factory

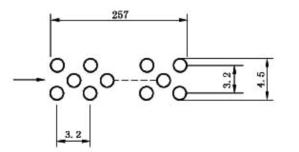

In the context of a testing factory specializing in cable production, hot set testing is often integrated into a broader quality assurance framework. The testing process typically involves heating the cable samples to a specified temperature for a predetermined duration. After this exposure, the cables are allowed to cool, and any changes in their dimensions or material properties are meticulously measured and documented. These results can inform design improvements, material selection, and end-user applications. Additionally, by establishing standardized testing protocols, manufacturers can ensure consistency across production batches, which is critical in maintaining product quality.

The advancements in technology have also influenced cable hot set testing procedures. Automated systems and sophisticated data analysis tools are increasingly used to enhance testing accuracy and efficiency. Such innovations allow for real-time monitoring of the cable’s performance, leading to quicker assessments and, ultimately, faster time-to-market for new products. Furthermore, with the growing emphasis on sustainability, testing factories are exploring eco-friendly materials and practices, aligning with the global movement towards reducing environmental impact.

In conclusion, cable hot set testing serves as a cornerstone in the manufacturing of electrical cables. It ensures safety, compliance with regulations, and the overall integrity of the product. As the demand for advanced electrical solutions continues to rise, testing factories must invest in efficient hot set testing procedures to not only uphold quality standards but also foster innovation in cable design. Ultimately, the commitment to rigorous testing reflects a dedication to excellence that is indispensable in today's competitive manufacturing environment.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy