Factories Specializing in Digital Projector Measurement Equipment and Advanced Technology Solutions

The Rise of Digital Projector Measuring Machines A Look at the Factories Behind Them

In the evolving landscape of manufacturing and quality assurance, digital projector measuring machines (DPMMs) have emerged as invaluable tools for precision measurement and inspection. These advanced devices play a crucial role in various industries, including automotive, aerospace, electronics, and metalworking. As the demand for high-precision components continues to rise, the factories producing these measuring machines are stepping up to meet the needs of the marketplace. This article explores the significance of DPMMs and the manufacturing processes involved in their creation.

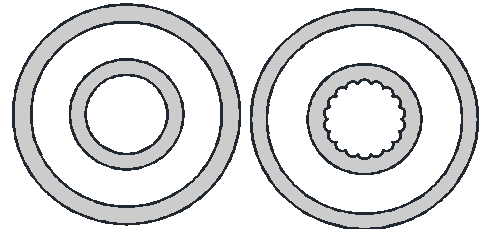

Digital projector measuring machines utilize optical projection technology to magnify and measure the dimensions of a workpiece accurately. These machines project a shadow of the item onto a screen, allowing operators to analyze geometric features with great precision. Key attributes such as lengths, angles, and radii can be measured quickly and efficiently, making DPMMs a staple in quality control laboratories and production environments.

The factories that design and manufacture digital projector measuring machines are specialized environments equipped with advanced technology and skilled labor. The manufacturing process begins with a thorough understanding of the target market's requirements, which drives design innovations. Engineers and designers work collaboratively to optimize the optics, illumination, and electronic components that make up these machines. The integration of sophisticated software for measurement analysis is also crucial, as it enables seamless data acquisition and enhances user experience.

Quality control is paramount in the production of DPMMs. Factories implement rigorous testing protocols at every stage of manufacturing to ensure that the machines meet stringent performance standards. This includes checking the alignment of optical components, the accuracy of mechanical parts, and the functionality of the software. Some manufacturers even employ calibrated measuring instruments to test and verify the accuracy of their machines before they leave the factory floor.

digital projector measuring machine factories

Furthermore, the demand for customization is driving factories to adapt their production processes. Many clients require specific features tailored to their unique applications. This has led manufacturers to develop modular machines that can easily be configured to meet varied measurement needs. Factories now focus not only on producing standardized models but also on accommodating bespoke requests, which can include specialized optics, different projection sizes, and customized software solutions.

As we delve into the global landscape of DPMMs, certain regions stand out as leaders in manufacturing. Countries with strong engineering faculties and a history of precision manufacturing, like Germany, Japan, and the United States, are known for producing high-quality digital projector measuring machines. However, the rise of industry in emerging markets has led to increased competition. Factories in these regions are leveraging modern technology and competitive pricing to capture market share.

Sustainability is another vital consideration for factories producing DPMMs. Manufacturers are increasingly aware of their environmental footprint and are striving to implement sustainable practices. This includes optimizing resource usage, reducing waste during production, and ensuring that machines are energy-efficient. Investing in environmentally friendly practices not only benefits the planet but also appeals to customers who prioritize sustainability.

In conclusion, digital projector measuring machines are essential tools in maintaining the high standards of precision required in modern manufacturing. The factories behind these machines are at the forefront of innovation, driven by the need for accuracy, customization, and sustainability. As technology continues to advance, we can expect to see even more refined and capable measuring solutions, helping industries to meet the challenges of a rapidly changing technological landscape.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy