wire bending test machine

The Wire Bending Test Machine Essential Equipment for Quality Assurance

In the manufacturing and construction industries, the reliability and durability of materials are paramount. One critical aspect of this reliability is understanding how materials respond to bending forces, particularly metals like wire. To evaluate this response and ensure material performance, engineers and quality assurance teams frequently employ a specialized tool known as the wire bending test machine. This article delves into the functionality, importance, and application of wire bending test machines.

Understanding Wire Bending Test Machines

Wire bending test machines are specialized devices designed to perform bending tests on wire products. These machines operate by applying a controlled bending force to the wire, allowing engineers to analyze the material's elastic and plastic deformation characteristics. The machines can simulate various bending scenarios to assess how the wire will perform under real-world conditions.

Typically, a wire bending test machine consists of a robust frame, a bending mechanism, and control systems for adjusting parameters such as bending angle, speed, and load. Many modern machines are equipped with advanced software that records data during the testing process, making it easier to analyze results and draw conclusions.

The Importance of Bending Tests

Bending tests are crucial in determining a wire's performance attributes, including its tensile strength, ductility, and fatigue resistance. By understanding these characteristics, manufacturers can ensure that their products will withstand the stresses they will face in real applications.

1. Quality Control In industries where safety and reliability are non-negotiable, such as construction or automotive, bending tests help in ensuring that materials meet specific standards and regulations. A wire that fails to endure bending stress can lead to catastrophic failures and safety hazards.

2. Material Selection Engineers often face the challenge of selecting the appropriate wire material for a specific application. Conducting bending tests allows for a comparative analysis of different wire materials, enabling manufacturers to choose the most suitable option for their needs.

wire bending test machine

3. Design Optimization Wire bending test machines not only help in assessing existing materials but also play a pivotal role in the research and development of new materials. By evaluating how different compositions and treatments affect bending performance, engineers can optimize designs for better performance and cost-effectiveness.

Applications Across Industries

The versatility of wire bending test machines means they find applications across various industries.

- Automotive Industry In the automotive sector, wire used in components like springs and suspension systems undergoes rigorous testing to ensure reliability and safety. Bending tests verify the ability of these components to handle dynamic loads and stresses.

- Construction In construction, wire is often used in reinforced concrete and structural applications. Ensuring that these wires can withstand bending forces is essential for the overall integrity and safety of buildings and infrastructure.

- Electronics The electronics industry uses fine wire in various components, including connectors and circuits. Bending tests help determine the longevity and reliability of these components, particularly in portable electronic devices that undergo frequent handling.

Conclusion

The wire bending test machine is an invaluable asset for manufacturers and engineers seeking to guarantee the quality and reliability of wire products. By facilitating precise testing of bending properties, these machines enable informed decision-making in material selection, product design, and quality assurance. As industries continue to evolve and demand higher standards for materials, the role of wire bending test machines will remain crucial in ensuring that standards are met, and performance is optimized. Investing in such technology not only enhances product safety but also contributes to the overall efficiency and success of manufacturing processes. As the world continues to innovate, understanding and testing the fundamentals of material performance will remain essential.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

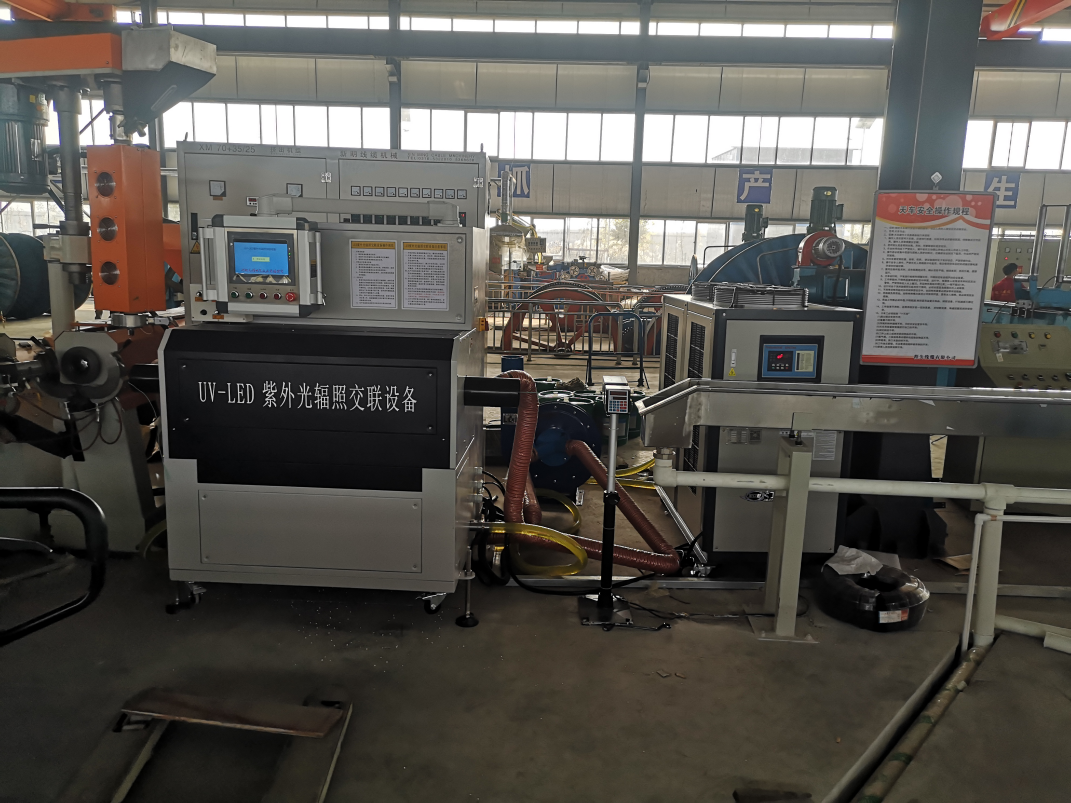

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy