cable repeated bending tester company

The Importance of Cable Repeated Bending Testers in Quality Assurance

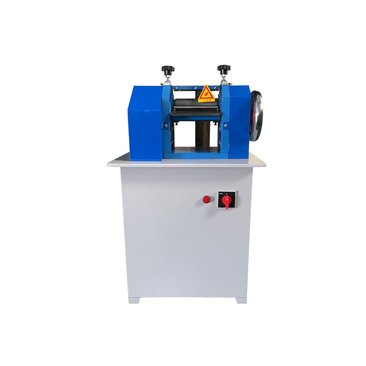

In today's technological landscape, where connectivity is paramount, the reliability of cables is crucial. This is where cable repeated bending testers become indispensable to manufacturers and quality assurance teams. These specialized machines are designed to evaluate the durability and performance of cables under repeated bending conditions, ensuring that they can withstand the rigors of daily use in various applications.

Understanding Cable Degradation

Cables, whether they are for power, data transfer, or communication, are subject to physical stress over their lifetimes. One of the most common forms of stress is bending, which can lead to micro-cracks, insulation breakdown, and eventual failure. As devices become more compact and require flexible cabling, the risk of damage from bending increases. Thus, manufacturers need a reliable method to assess how well their products can handle stress without compromising performance.

The Role of Repeated Bending Testers

Cable repeated bending testers replicate the repetitive motion that cables endure in real-life scenarios. These machines are capable of simulating various bending angles and frequencies, providing a consistent and controlled environment for rigorous testing. By subjecting cables to a predetermined number of cycles, manufacturers can gather valuable data on the longevity and reliability of their products.

Not only do these testers evaluate the physical integrity of the cables, but they also help in measuring electrical performance degradation caused by bending. Parameters such as resistance, capacitance, and signal quality can be monitored throughout the testing period, helping to ensure that the cable meets the required performance standards even after extensive bending.

cable repeated bending tester company

Key Features of Cable Repeated Bending Testers

Modern cable repeated bending testers come equipped with advanced features that enhance their functionality and precision. Many models allow customization of bending angles and speeds, enabling manufacturers to simulate specific conditions relevant to their products. Additionally, digital interfaces often provide real-time monitoring and analysis, streamlining the quality assurance process.

Safety is also a critical aspect of these machines. High-quality testers are designed with protective casings and emergency stop functions to ensure safe operations for the personnel involved. Moreover, maintaining a strict adherence to industry standards, such as ISO and IEC guidelines, ensures that the testing process is standardized and reliable.

Final Thoughts

Investing in cable repeated bending testers is essential for manufacturers looking to enhance their product quality and ensure customer satisfaction. By rigorously testing their cables under realistic conditions, manufacturers can identify potential issues before products reach the market, reducing the likelihood of returns and enhancing their reputation for quality.

In conclusion, as technology continues to evolve, the importance of dependable cables will only increase. Cable repeated bending testers serve as a critical tool in the quest for quality assurance, ensuring that cables can endure the stresses of everyday use while providing optimal performance. For any manufacturer dedicated to excellence, these testers are not just a luxury; they are an essential component of the production process.

-

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy