Jan . 23, 2025 05:14

Back to list

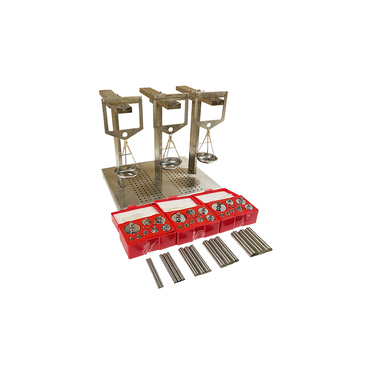

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

In the intricate world of electrical engineering, the quality and reliability of custom cables cannot be overstated. These components are the backbone of countless industrial applications, managing power and communication in mining, aerospace, renewable energy, and more. One critical aspect of ensuring the performance and safety of custom cables is the heat pressure test—a procedure designed to evaluate a cable's ability to withstand thermal and mechanical stress. This article delves into the importance of the heat pressure test for custom cables, guided by experiential insights from industry experts, ensuring a comprehensive understanding of its impact on product reliability.

Trustworthiness in custom cables is critical, especially as industries scale in both complexity and demand. A failure in a cable can lead not only to operational hazards but also to significant safety risks. From powering life-sustaining medical devices in hospitals to keeping data servers running smoothly in tech firms, the significance of faultless cable performance cannot be overlooked. The heat pressure test is an assurance to clients that their investment in custom cables will protect their operations and maintain their standards. A supplier of renewable energy systems adds an insightful perspective on this necessity For us, efficiency and reliability go hand-in-hand. If a system fails due to thermal stress, it can jeopardize both energy output and long-term goals of sustainability. The meticulousness of the heat pressure test guarantees that our cables sustain high-performance levels throughout their expected lifespan. The expertise and accountability that go hand-in-hand with conducting and certifying the results of a heat pressure test also serve to comfort customers and end-users. Knowing that cables have been rigorously tested and have passed stringent industry checks reassures buyers of their investment’s longevity and safety. In conclusion, the heat pressure test for custom cables is not merely a routine examination; it is a vital validation process that underscores commitment to quality and reliability. By identifying potential weaknesses before cables reach real-world scenarios, manufacturers arm industries with the confidence to operate at maximum efficiency, regardless of environmental challenges. As industries become more dependent on custom cable solutions, the heat pressure test remains a linchpin in building trust, ensuring safety, and guaranteeing sustained performance. In a landscape where the minutest failure can translate into significant repercussions, those selecting cable solutions must prioritize products that have seamlessly undergone such rigorous evaluations.

Trustworthiness in custom cables is critical, especially as industries scale in both complexity and demand. A failure in a cable can lead not only to operational hazards but also to significant safety risks. From powering life-sustaining medical devices in hospitals to keeping data servers running smoothly in tech firms, the significance of faultless cable performance cannot be overlooked. The heat pressure test is an assurance to clients that their investment in custom cables will protect their operations and maintain their standards. A supplier of renewable energy systems adds an insightful perspective on this necessity For us, efficiency and reliability go hand-in-hand. If a system fails due to thermal stress, it can jeopardize both energy output and long-term goals of sustainability. The meticulousness of the heat pressure test guarantees that our cables sustain high-performance levels throughout their expected lifespan. The expertise and accountability that go hand-in-hand with conducting and certifying the results of a heat pressure test also serve to comfort customers and end-users. Knowing that cables have been rigorously tested and have passed stringent industry checks reassures buyers of their investment’s longevity and safety. In conclusion, the heat pressure test for custom cables is not merely a routine examination; it is a vital validation process that underscores commitment to quality and reliability. By identifying potential weaknesses before cables reach real-world scenarios, manufacturers arm industries with the confidence to operate at maximum efficiency, regardless of environmental challenges. As industries become more dependent on custom cable solutions, the heat pressure test remains a linchpin in building trust, ensuring safety, and guaranteeing sustained performance. In a landscape where the minutest failure can translate into significant repercussions, those selecting cable solutions must prioritize products that have seamlessly undergone such rigorous evaluations.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy