Exporters of Winding and Torsion Testing Equipment for Quality Assurance in Manufacturing

The Role of Winding and Torsion Testers in Quality Control

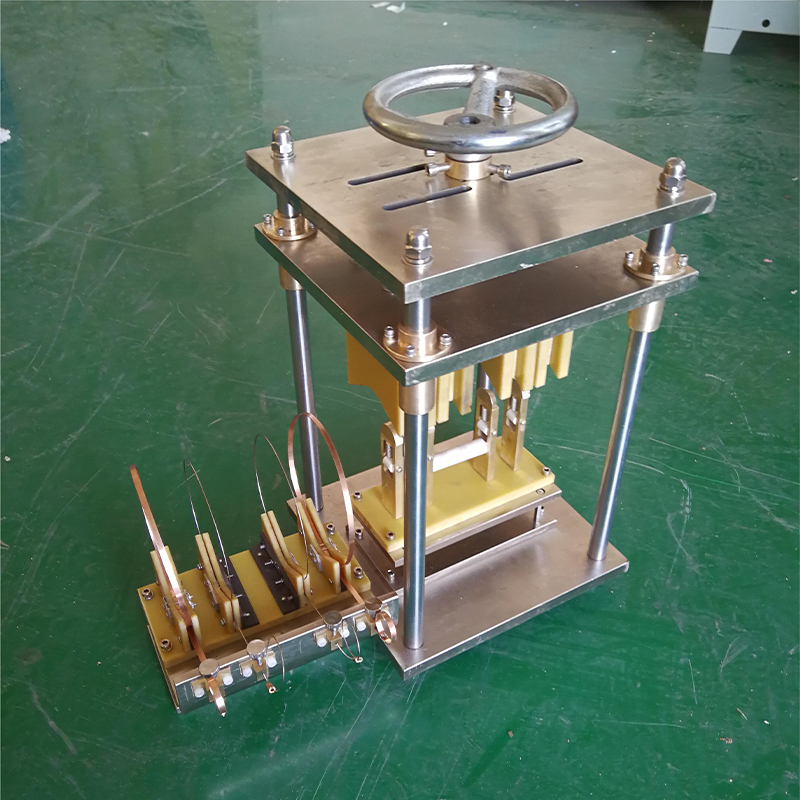

In the realm of manufacturing and material testing, winding and torsion testers play a crucial role in ensuring product quality and durability. As industries continue to advance, particularly in sectors such as textiles, aerospace, and automotive, the demand for precise testing instruments has increased significantly. Exporters specializing in winding and torsion testers contribute not only to product reliability but also to adhering to international quality standards.

Understanding Winding and Torsion Testing

Winding tests are crucial for evaluating the mechanical properties of materials used in ropes, cables, and textiles. These tests assess how materials behave under different winding conditions and help identify their tensile strength, elasticity, and durability. Torsion testing, on the other hand, measures a material's resistance to twisting forces. This is particularly important in applications where materials are subjected to high rotational forces, such as in automotive components or structural applications.

Combining these tests provides a comprehensive understanding of a material's performance in real-world conditions, contributing to product development and refinement. Manufacturers utilizing winding and torsion testers can better predict failures, improve product design, and enhance overall safety.

The Export Market for Winding and Torsion Testers

The global market for winding and torsion testers has observed significant growth, driven by the increasing requirements for stringent quality control across various industries. Exporters of these testing devices are strategically important as they provide advanced technology that enables manufacturers worldwide to maintain competitive advantage.

Countries such as Germany, Japan, and the United States are known for their innovation in testing technology, producing high-precision instruments that are sought after in international markets

. These exporters not only cater to local industries but also supply manufacturers in emerging markets, reinforcing the globalized nature of the manufacturing industry.winding and torsion tester exporters

Features of Advanced Winding and Torsion Testers

Modern winding and torsion testers come equipped with an array of features that enhance their functionality and usability. Digital displays, data logging capabilities, and automated testing protocols are common features that allow for accurate measurements and streamlined operations. Many testers also provide options for customization, enabling manufacturers to tailor tests to their specific needs.

Moreover, advancements in software integration allow for real-time data analysis and reporting, making it easier for quality assurance teams to make informed decisions quickly. As a result, companies can implement corrective actions more swiftly, reducing downtime and increasing productivity.

The Importance of Compliance and Standards

For exporters, compliance with international standards such as ISO and ASTM is of paramount importance. These standards dictate the methodologies for performing winding and torsion tests, ensuring that results are reliable and comparable across different laboratories and industries. Manufacturers relying on these testers must also maintain compliance to guarantee that their products meet the required specifications.

Exporters of winding and torsion testers invest significantly in understanding and adhering to these standards. This not only helps to establish their reputation in the global market but also assures clients that their testing equipment is of the highest quality, capable of providing accurate and reliable results.

Conclusion

Winding and torsion testers are vital tools in the manufacturing landscape, enabling companies to deliver safe, high-quality products. As industries continue to evolve, the role of exporters in providing advanced testing solutions becomes increasingly important. By upholding international standards and embracing technological advancements, these exporters contribute significantly to the overall integrity and reliability of products in various sectors. With the ongoing globalization of the manufacturing industry, the demand for quality testing equipment is likely to grow, ensuring that winding and torsion testers remain essential in the ongoing quest for product excellence.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy