ian. . 21, 2025 01:45

Back to list

optical measurement machines

Optical measurement machines are revolutionizing the landscape of precision engineering and quality assurance across numerous industries. Their implementation ensures products meet stringent quality and design specifications by providing precise and reliable measurements. Here's an in-depth exploration of the advantages and applications of these machines, guided by firsthand experiences, expert opinions, and authoritative insights, to enhance your understanding and foster trust in these technological marvels.

Authoritative institutions, including leading research labs and quality assurance bodies, frequently conduct studies to validate the efficacy and reliability of optical measurement machines. Their findings underline the consistency and accuracy of these machines compared to traditional measurement methods like Coordinate Measuring Machines (CMMs). The high-resolution imaging and fast processing speed ensure comprehensive data collection, aiding in thorough analysis and informed engineering decisions. Trust in optical measurement machines is intrinsically linked to their adoption by industries governed by rigorous standards and regulations. Compliance with international standards such as ISO and ASME further solidifies their reputation. Case studies reveal substantial improvements in overall product quality and customer satisfaction among companies employing these technologies, underscoring their vital role in modern manufacturing environments. In summary, optical measurement machines are indispensable tools for industries that value precision, speed, and reliability. By offering a non-contact, flexible, and efficient measurement solution, they address the growing demands for quality and innovation in competitive markets. Insights from seasoned professionals, supported by authoritative research and industry compliance, establish these machines as trustworthy solutions for advanced measurement needs. Companies embracing this technology not only benefit from streamlined operations but also solidify their standing as leaders in quality and innovation.

Authoritative institutions, including leading research labs and quality assurance bodies, frequently conduct studies to validate the efficacy and reliability of optical measurement machines. Their findings underline the consistency and accuracy of these machines compared to traditional measurement methods like Coordinate Measuring Machines (CMMs). The high-resolution imaging and fast processing speed ensure comprehensive data collection, aiding in thorough analysis and informed engineering decisions. Trust in optical measurement machines is intrinsically linked to their adoption by industries governed by rigorous standards and regulations. Compliance with international standards such as ISO and ASME further solidifies their reputation. Case studies reveal substantial improvements in overall product quality and customer satisfaction among companies employing these technologies, underscoring their vital role in modern manufacturing environments. In summary, optical measurement machines are indispensable tools for industries that value precision, speed, and reliability. By offering a non-contact, flexible, and efficient measurement solution, they address the growing demands for quality and innovation in competitive markets. Insights from seasoned professionals, supported by authoritative research and industry compliance, establish these machines as trustworthy solutions for advanced measurement needs. Companies embracing this technology not only benefit from streamlined operations but also solidify their standing as leaders in quality and innovation.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

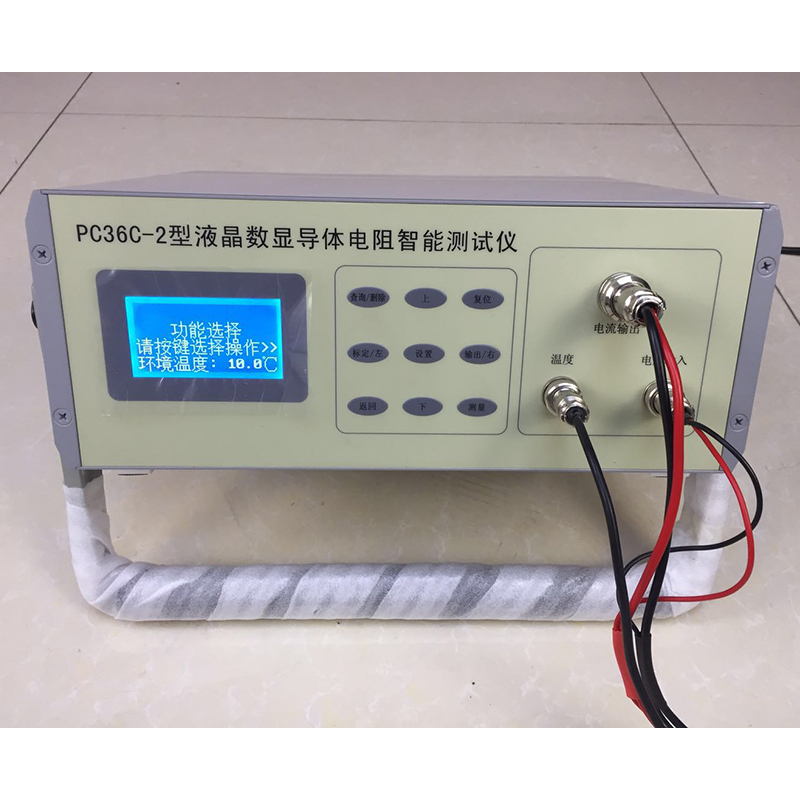

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy