resistance fixture manufacturer

The Importance of Resistance Fixture Manufacturers in Today's Industries

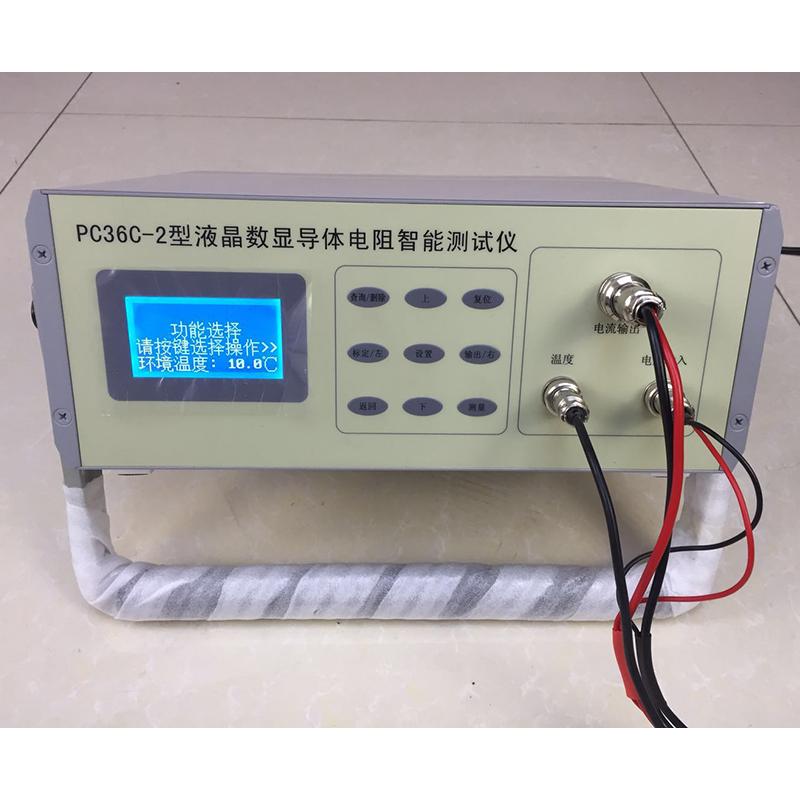

In the ever-evolving landscape of manufacturing and engineering, the role of resistance fixture manufacturers has gained paramount importance. These specialized companies design and produce fixtures that are crucial for testing and measuring the resistance of various materials and components. As industries increasingly rely on precise measurements for quality assurance, safety, and efficiency, the demand for high-quality resistance fixtures has surged.

Resistance fixtures are essential tools in numerous sectors, including automotive, aerospace, electronics, and materials science. They are used to evaluate the electrical resistance of materials, ensuring that products meet stringent industry standards. A well-designed resistance fixture can help identify defects, improve product quality, and accelerate research and development processes. For manufacturers, this means reduced downtime, lower production costs, and enhanced overall performance.

One of the critical aspects of a resistance fixture manufacturer is their ability to customize products to meet specific client needs. Every industry has its own set of challenges, and a one-size-fits-all approach seldom suffices. Leading manufacturers work closely with clients to understand their unique requirements, offering tailored solutions that enhance testing accuracy and reliability. This collaborative approach not only fosters innovation but also strengthens partnerships within the supply chain.

resistance fixture manufacturer

Moreover, the integration of advanced technologies in the production of resistance fixtures has transformed the landscape. Manufacturers are increasingly adopting automation, artificial intelligence, and data analytics to improve the design and testing processes. This technological shift not only enhances precision but also optimizes production efficiency, allowing manufacturers to produce fixtures that are both cost-effective and high-performing.

Another notable trend is the growing emphasis on sustainability in the manufacturing process. Resistance fixture manufacturers are also increasingly focusing on eco-friendly practices by utilizing sustainable materials and energy-efficient production methods. Companies that prioritize sustainability not only contribute to environmental preservation but also appeal to a broader market that values eco-conscious practices.

In conclusion, resistance fixture manufacturers play a vital role in ensuring the integrity and quality of products across various industries. Their ability to provide customized solutions, embrace technological advancements, and commit to sustainable practices positions them as essential partners in the manufacturing process. As industries continue to evolve, the contributions of these manufacturers will be instrumental in driving innovation and maintaining high standards of quality and performance. Investing in exceptional resistance fixtures is not just a technical necessity; it is a strategic advantage for businesses aiming to thrive in a competitive market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy