feb. . 17, 2025 18:18

Back to list

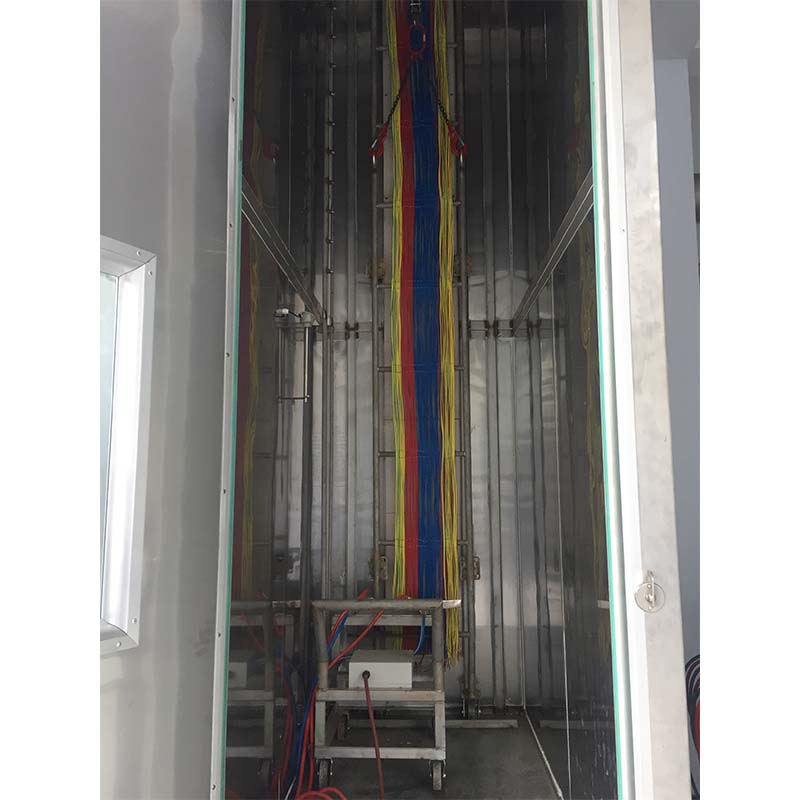

smoke density chamber test factory

Navigating the world of material testing can be daunting, especially when it comes to understanding the intricacies of the smoke density chamber test. As an industry expert with years of experience working closely with prominent test facilities, I provide a comprehensive look into why the smoke density chamber test is crucial, and how a dedicated factory environment elevates the standard of these tests.

Authoritativeness is another attribute fostered within the confines of a specialized factory. Facilities dedicated to smoke density testing often collaborate with regulatory bodies, research institutions, and industry leaders to stay abreast of the latest developments and legislative changes. This collaboration enhances the factory's authority, enabling it to provide insights that go beyond mere compliance, offering foresight into future trends and requirements in material safety. Trustworthiness is perhaps the most intangible yet vital component when choosing a smoke density chamber test factory. Reliability in results fosters trust, which is built through transparency in testing methodologies and data reporting. Factories adhering to ethical practices openly share their procedures, calibrations, and validation techniques with clients. This transparency not only builds trust but also enables clients to make informed decisions about material choices and safety implementations. Furthermore, dedicated test factories often engage in continuous improvement initiatives, regularly updating and calibrating equipment and processes to maintain cutting-edge capabilities. This commitment to excellence and innovation underpins the trust that clients place in their testing services, reinforcing the factory's reputation as a leader in smoke density testing. In conclusion, the integration of a factory setting tailored specifically for smoke density chamber tests offers unmatched benefits in terms of precision, expertise, authority, and trust. These dedicated environments ensure that tests are conducted under optimal conditions, utilizing advanced technology and adhering to internationally recognized standards, while also fostering a culture of transparency and continuous improvement. For industries where safety and compliance are paramount, choosing a reputable smoke density chamber test factory represents an indispensable investment in quality and reliability.

Authoritativeness is another attribute fostered within the confines of a specialized factory. Facilities dedicated to smoke density testing often collaborate with regulatory bodies, research institutions, and industry leaders to stay abreast of the latest developments and legislative changes. This collaboration enhances the factory's authority, enabling it to provide insights that go beyond mere compliance, offering foresight into future trends and requirements in material safety. Trustworthiness is perhaps the most intangible yet vital component when choosing a smoke density chamber test factory. Reliability in results fosters trust, which is built through transparency in testing methodologies and data reporting. Factories adhering to ethical practices openly share their procedures, calibrations, and validation techniques with clients. This transparency not only builds trust but also enables clients to make informed decisions about material choices and safety implementations. Furthermore, dedicated test factories often engage in continuous improvement initiatives, regularly updating and calibrating equipment and processes to maintain cutting-edge capabilities. This commitment to excellence and innovation underpins the trust that clients place in their testing services, reinforcing the factory's reputation as a leader in smoke density testing. In conclusion, the integration of a factory setting tailored specifically for smoke density chamber tests offers unmatched benefits in terms of precision, expertise, authority, and trust. These dedicated environments ensure that tests are conducted under optimal conditions, utilizing advanced technology and adhering to internationally recognized standards, while also fostering a culture of transparency and continuous improvement. For industries where safety and compliance are paramount, choosing a reputable smoke density chamber test factory represents an indispensable investment in quality and reliability.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy