Tensile Testing Machine for Material Strength Evaluation and Performance Analysis

Understanding the Tensile Tester Machine A Comprehensive Overview

The tensile tester machine, often referred to as a tensile testing machine or tensile strength tester, is a crucial instrument in materials science and engineering. It is designed to measure the mechanical properties of materials, particularly their tensile strength and elongation properties. These measurements are essential for determining how materials will perform under various types of stress and strain, which is critical for applications across multiple industries, including construction, automotive, aerospace, and manufacturing.

What is a Tensile Tester Machine?

A tensile tester machine operates by applying a uniaxial tensile load to a specimen—typically a sample cut from a material such as metal, plastic, or fabric—and recording the response of the material as it is stretched until failure. The machine generally consists of a load frame, grips for holding the specimen, a measuring system to record elongation, and a computer interface for data analysis.

Key Components

1. Load Frame The frame provides the support and stability needed to apply tension to the specimen without deformation. It often features a hydraulic or electromechanical system that can generate significant force to test both weak and robust materials.

2. Grips Gripping the specimen securely is vital for accurate testing. There are various types of grips, including wedge grips, pneumatic grips, and hydraulic grips, each suited for different materials and testing requirements.

3. Load Cell This component measures the amount of force being applied to the specimen. It converts the mechanical force into an electrical signal, which is then recorded for analysis.

4. Extensometer To measure the elongation of the specimen with precision, an extensometer is often attached. This device measures the distance between two points on the material to provide accurate strain data.

5. Software Modern tensile testers are equipped with sophisticated software that allows for real-time data collection, analysis, and reporting. Users can customize the testing parameters and generate detailed reports on the mechanical properties of the tested materials.

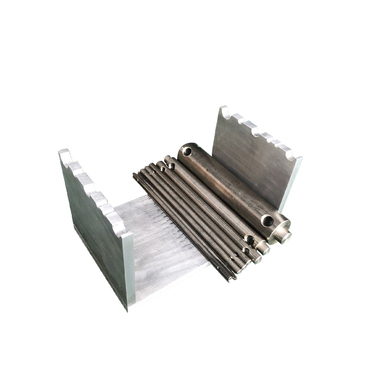

tensile tester machine

Testing Process

The tensile testing process typically begins with preparing the specimen by cutting it to specific dimensions, often in the shape of a dog bone to ensure uniform cross-sectional areas. Once prepared, the specimen is securely placed in the grips of the tensile tester. The machine is then calibrated, and the test starts by gradually applying the force while the machine measures the stress (force per unit area) and strain (deformation).

As the tension increases, the material will undergo elastic deformation, where it will return to its original shape once the load is removed, until it reaches the yield point. Beyond this point, plastic deformation occurs, and the specimen will not return to its original shape. The ultimate tensile strength is reached when the material fails, and the fracture point is recorded.

Applications of Tensile Testing

Tensile testing is crucial for various applications, including

- Material Quality Control Industries use tensile testers to ensure that materials meet specific grade requirements before they are utilized in manufacturing processes.

- Research and Development Engineers and scientists utilize tensile testing to develop new materials or improve existing ones, thereby enhancing performance and safety in products.

- Failure Analysis By understanding how materials fail—whether through fracture, yielding, or fatigue—engineers can better design products to withstand expected loads and reduce the risk of failure in service.

Conclusion

The tensile tester machine is an indispensable tool in today's materials testing landscape. Its ability to provide detailed insights into the mechanical behavior of materials under tensile stress allows engineers and manufacturers to ensure safety and reliability in their products. As technology advances, the capabilities of tensile testers will continue to improve, offering even greater accuracy and efficiency, thus playing a pivotal role in the ongoing quest for innovation in material sciences.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy