15 Ton Tensile Tester Manufacturer for Quality Material Testing Solutions

Understanding the Role of a 15% 20 Ton Tensile Tester Factory in Material Testing

In the realm of material science and engineering, the ability to test the mechanical properties of materials is paramount. Among the various methods employed in material testing, tensile testing stands out as one of the most fundamental processes. It provides critical data on how materials behave under tensile (pulling) forces. A vital component in this testing process is the tensile tester, and among the various types available, the 15% 20 ton tensile tester holds a significant position within specialized factories.

What is a Tensile Tester?

A tensile tester, also known as a tensile testing machine, is an instrument used to measure a material's strength, ductility, and other mechanical properties through the application of a stretching force until the material fails. The 20-ton capacity of a tensile tester indicates the maximum load it can apply to the specimen, while the designation of '15%' typically reflects the desired elongation or strain of the material being tested.

The Importance of the 15% 20 Ton Capacity

The specification of 15% in a 20-ton tensile tester is crucial for various engineering applications, particularly in industries such as construction, manufacturing, and aerospace. Materials that can elongate up to 15% before failure are often utilized in applications where flexibility and high tensile strength are necessary. This is vital for ensuring that the materials can withstand significant forces without breaking or deforming permanently.

The Manufacturing Process in a Tensile Tester Factory

A factory dedicated to manufacturing 15% 20 ton tensile testers adheres to stringent quality controls and technical precision. The process typically begins with the design phase, where engineers utilize computer-aided design (CAD) software to develop detailed specifications. Once the designs are finalized, manufacturing commences, often employing high-grade materials like steel and aluminum to ensure durability and accuracy.

15 ton tensile tester factory

Each component of the tensile tester, such as the frame, grips, and load cells, is meticulously crafted to ensure that they can withstand the high stresses encountered during testing. After fabrication, these components undergo rigorous quality assurance tests to guarantee their performance aligns with international standards.

Calibration and Testing Procedures

Calibration is a critical aspect of manufacturing tensile testers. A factory producing these machines employs precise methods to ensure that the load and elongation readings are accurate. This involves using standard reference weights and materials with known properties to adjust the machine's readings. Regular calibration checks are essential not just for new machines but also for ensuring consistent performance in existing testers, particularly in research and production settings.

Once a tensile tester is manufactured and calibrated, it undergoes extensive testing to assess its performance. This phase helps manufacturers identify any defects or inconsistencies before the machine is delivered to a buyer. The testing process simulates real-world conditions, challenging the machine with different materials to ensure it delivers reliable data.

Applications in Various Industries

The 15% 20 ton tensile tester finds applications across diverse fields. In the automotive industry, for example, it is employed to test metals and composites used in vehicle frameworks to ensure they meet safety standards. In the construction sector, it assesses materials like steel and concrete that are critical for building structures. Such testing is not only essential for quality assurance but also for regulatory compliance.

Conclusion

The role of a 15% 20 ton tensile tester factory is indispensable in the landscape of material testing. By developing and manufacturing high-quality tensile testers, these factories contribute significantly to various industries' ability to analyze and ensure the integrity of materials. As technology advances, the demand for accurate and reliable material testing will only increase, driving innovation within these specialized factories. Through dedication to precision and quality, tensile tester factories uphold the standards that support safety and durability in engineering applications worldwide.

-

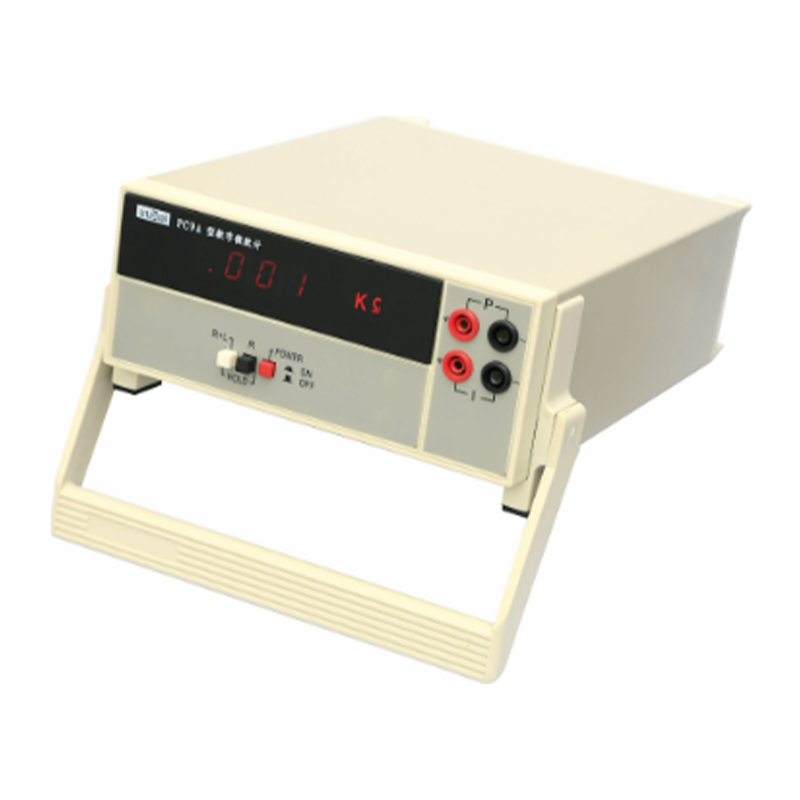

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy