cable thermal elongation test supplier

Understanding Cable Thermal Elongation Testing A Guide for Buyers

When it comes to ensuring the quality and reliability of electrical cables, thermal elongation testing is a vital assessment. This test measures how much a cable can expand due to temperature variations, which is crucial for applications where cables might experience significant thermal changes. For industries reliant on electrical cables, understanding this testing method is essential, especially when searching for a reliable supplier.

What is Thermal Elongation Testing?

Thermal elongation testing evaluates the length changes of a cable when subjected to varying temperatures. This testing is crucial because cables can expand and contract based on the temperature they encounter during use. If a cable elongates excessively, it may cause issues in installations, such as increased wear on connectors, cable damage, or even failures in electrical connectivity.

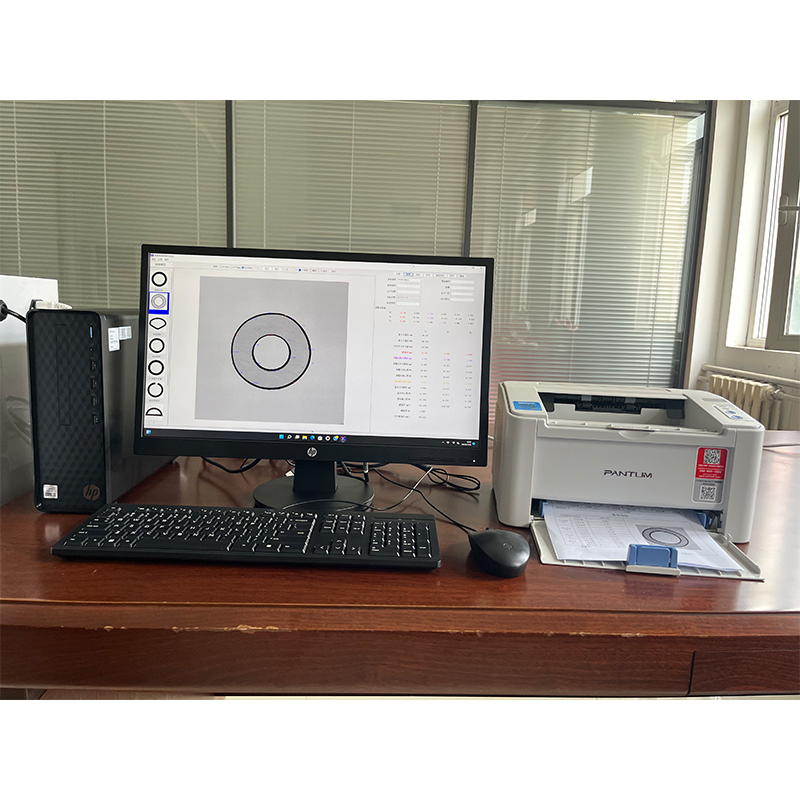

The process typically involves subjecting the cable to a standardized temperature change, allowing it to reach thermal equilibrium, and then measuring any length variations. Suppliers that provide this testing usually adhere to international standards, ensuring that the results are reliable and can be compared across different cables and applications.

Why Choose a Reliable Supplier?

As an industry professional, selecting a supplier that conducts thorough and certified thermal elongation tests is crucial for several reasons

cable thermal elongation test supplier

1. Quality Assurance A reputable supplier will ensure that all their cables have undergone rigorous testing, thereby reducing the risk of failure in real-world applications. Cables that have been properly tested for thermal elongation are less likely to lead to catastrophic failures, which can be costly in terms of repairs and downtime.

2. Compliance with Standards Many industries require compliance with specific standards regarding cable performance under thermal stress. A supplier who provides testing services usually meets these standards, which is essential for regulatory compliance and ensuring the safety of installations.

3. Enhanced Longevity Cables that are subjected to thorough thermal elongation tests tend to exhibit greater durability over time. By choosing a supplier that prioritizes this testing, companies can enhance the longevity of their installations and maintain operational efficiency.

4. Custom Solutions Many suppliers offer customized testing services that align with specific project requirements. This level of flexibility can be critical for projects demanding specialized cables or unique environmental conditions.

5. Expert Insight Suppliers that specialize in thermal elongation testing often have a wealth of knowledge about the factors affecting cable performance. Partnering with such experts can provide invaluable insights into material selection, installation methods, and maintenance practices.

Conclusion

In conclusion, cable thermal elongation testing is not just a regulatory requirement; it is a crucial step in ensuring the reliability and safety of cable-based systems. When searching for a supplier, prioritize those who provide comprehensive testing services, adhere to recognized standards, and can offer expert guidance. By doing so, you will not only protect your projects from potential failures but also contribute to the development of safer and more reliable electrical installations. Investing time in selecting the right partner will pay off in the long run, ensuring that your electrical systems perform optimally under varying thermal conditions.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy