custom cable repeated bending tester

Custom Cable Repeated Bending Tester Ensuring Durability and Reliability in Cable Design

In today's technology-driven world, cables are fundamental components that serve various applications, from simple household electronics to complex industrial machinery. However, the reliability and durability of these cables are paramount, especially in scenarios where they are subject to constant movement and bending. This is where a custom cable repeated bending tester plays a critical role in ensuring the quality and longevity of cable products.

The Importance of Bending Tests

Cables are often installed in environments where they undergo repeated flexing, twisting, and pulling. Over time, these physical stresses can lead to cable fatigue, resulting in insulation damage, conductor breakage, or, in worst-case scenarios, complete cable failure. Conducting bending tests helps manufacturers simulate real-world usage conditions, allowing them to assess a cable's performance and lifespan before it reaches the market.

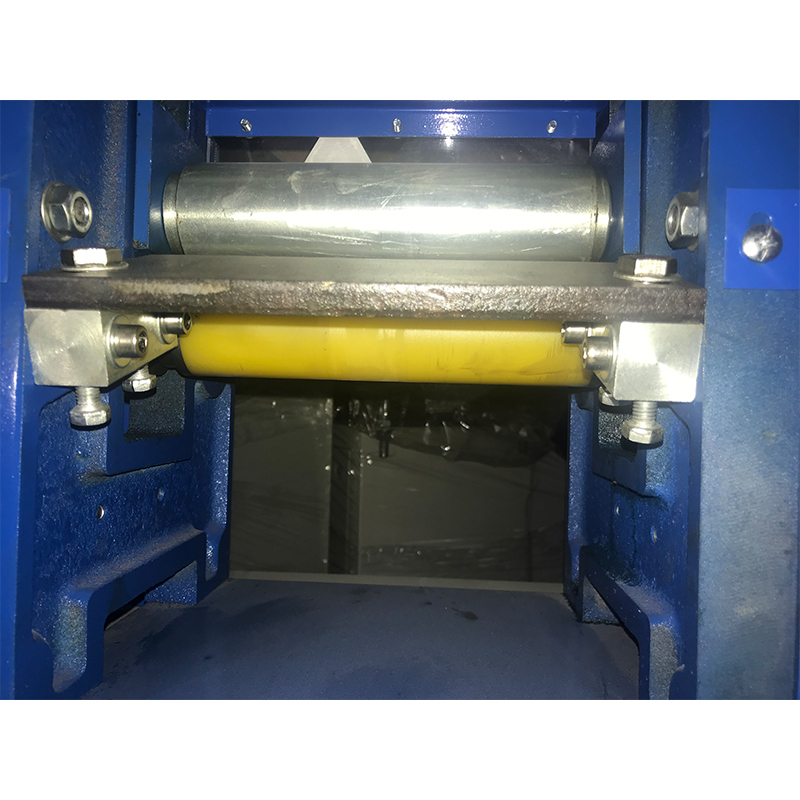

A custom cable repeated bending tester is designed to evaluate how well a cable can withstand a specified number of bending cycles without failing. This process typically involves bending the cable back and forth at a predetermined angle and radius, mimicking daily use conditions. By utilizing a specific testing machine, manufacturers can identify potential weaknesses in their cable designs early in the development phase.

Customization for Specific Needs

The versatility of a custom cable repeated bending tester lies in its ability to be tailored to specific testing requirements. Different cables may require different bending angles, frequencies, or cycle counts to accurately reflect their intended use. For example, a flexible data cable used in a robotic arm will undergo different bending patterns compared to a power cable used in stationary machinery.

Manufacturers can customize various parameters of the bending tester, including

1. Bending Angle and Radius Adjusting these dimensions can simulate the specific conditions that cables will face in their operational environments. 2. Cycle Count Different applications may require varying numbers of cycles, from hundreds to millions, to ensure comprehensive testing.

3. Environmental Conditions Testing can be conducted under specific environmental conditions—such as temperature and humidity—to mimic the operational environment of the cables.

custom cable repeated bending tester

4. Multiple Cable Types A versatile tester can accommodate various cable types (e.g., data, power, and hybrid cables) in a single system, leading to cost-effective testing solutions.

Advantages of Using a Repeated Bending Tester

1. Enhanced Reliability By proactively identifying weaknesses in cable designs, manufacturers can make the necessary adjustments, resulting in greater product reliability and customer satisfaction.

2. Cost-Effective Development Investing in a custom bending tester can save manufacturers money in the long run by minimizing product failures and reducing warranty claims.

3. Compliance Verification Many industries have stringent safety and performance standards that cables must meet. A reliable bending tester can help manufacturers ensure compliance with these regulations, allowing for smoother market entry.

4. Better Product Quality By implementing repeated bending tests, manufacturers can produce higher-quality cables that perform better in demanding applications, thus enhancing their market reputation.

Conclusion

As the demand for advanced cable solutions continues to grow, so does the need for thorough testing to ensure durability and safety. A custom cable repeated bending tester is invaluable for manufacturers aiming to produce reliable and sustainable cable products. By identifying potential vulnerabilities and ensuring compliance with industry standards, manufacturers can significantly enhance their product offerings, reduce costs associated with failures, and ultimately deliver superior solutions to their customers.

In a world where technology depends on the effectiveness of its components, investing in reliable testing solutions like a custom cable repeated bending tester is not just an option—it’s a necessity for maintaining competitiveness and ensuring consumer safety in the market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy