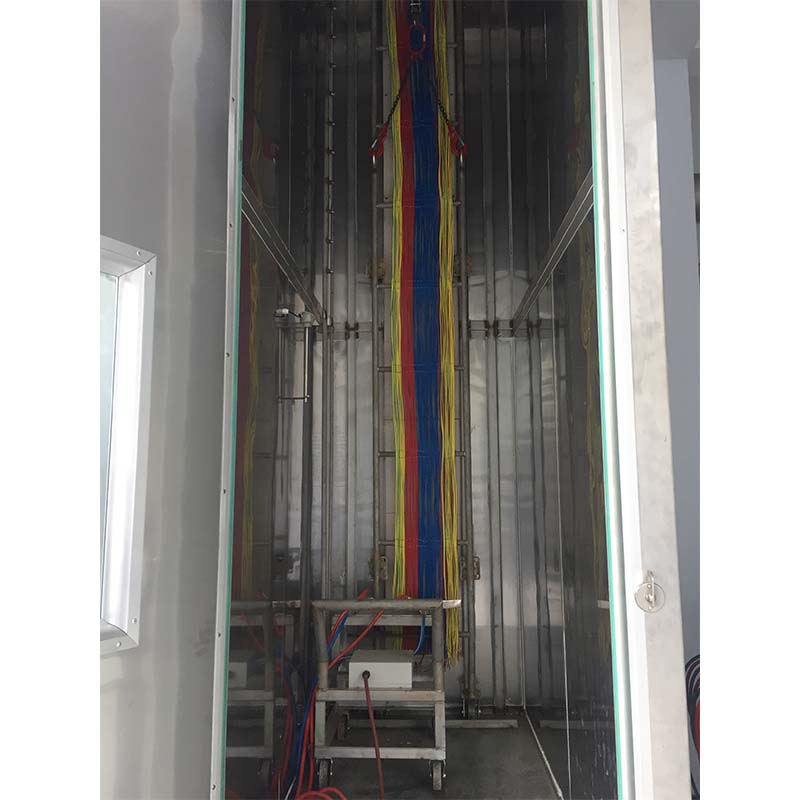

custom electronic universal tensile testing machine

Custom Electronic Universal Tensile Testing Machine An Overview

In the realm of materials testing, the importance of accurate measurements and reliable data cannot be overstated. Among the various testing machines used to evaluate material properties, the custom electronic universal tensile testing machine stands out for its versatility and precision. This article delves into the functionalities, benefits, and customizability of these testing machines, underscoring their significance in research and industrial applications.

Understanding the Basics

A tensile testing machine is designed to measure the tensile strength of materials, which is a critical property in various industries, including construction, aerospace, automotive, and manufacturing. These machines are capable of pulling materials such as metals, plastics, and composites to determine parameters like yield strength, ultimate tensile strength, and elongation.

The universal aspect refers to the machine's capability to test a wide range of materials under different conditions, making it suitable for various applications. Traditionally, tensile testing machines were mechanical, but the advent of electronic systems has significantly enhanced their performance, accuracy, and user-friendliness.

Key Features of Custom Electronic Universal Tensile Testing Machines

1. Precision Control Custom electronic universal tensile testing machines are equipped with advanced control systems that allow operators to set specific parameters for their tests. This precision helps in obtaining high-quality data, which is essential for research and quality assurance.

2. User-Friendly Interface Most modern tensile testing machines come with intuitive software interfaces that make it easy for users to input data and analyze results. This ease of use is critical in laboratory settings, where time efficiency is paramount.

3. Data Acquisition and Analysis These machines are often integrated with sophisticated data acquisition systems that can record and analyze test results in real time. This ensures that any anomalies can be quickly identified, allowing for immediate corrective actions.

custom electronic universal tensile testing machine

4. Customizable Testing Configurations One of the standout features of these machines is their customizability. Depending on the specific requirements, manufacturers can adjust various parameters such as load capacity, speed, and attachment types. This makes the machines suitable for testing diverse materials.

5. Multi-Functionality Beyond tensile testing, many modern machines can perform compression, bending, and cyclic tests. This multi-functionality enables laboratories to conduct a wide range of assessments using a single device, thus saving space and resources.

Advantages of Customization

Customization is a significant advantage when it comes to electronic universal tensile testing machines. The ability to tailor the machine to specific requirements allows organizations to enhance their testing capabilities without investing in multiple devices. For example, a factory that primarily deals with polymers might need a machine with specific grips and temperatures that accommodate the unique properties of its materials. Custom solutions also ensure compliance with industry standards and regulations, which can vary by sector.

Applications Across Industries

The applications of custom electronic universal tensile testing machines are vast and varied. In construction, they are used to test the tensile strength of concrete and steel to ensure structural integrity. In the aerospace industry, materials must meet rigorous safety standards, making precise tensile testing essential. In the automotive sector, manufacturers rely on these machines to ensure that components can withstand the stresses of operation.

Conclusion

Custom electronic universal tensile testing machines play an indispensable role in modern material testing, offering precision, versatility, and extensive customization options. By investing in such technologies, industries can not only ensure product quality but also innovate and improve their materials for future applications. As technology continues to advance, these machines will undoubtedly play a crucial role in materials science and engineering, paving the way for safer, more efficient, and higher-performing products across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy