Supplier of Equipment for Testing Tensile Strength in Various Materials and Applications

The Importance of Choosing the Right Tensile Strength Testing Equipment Supplier

In the manufacturing and materials testing industries, tensile strength testing plays a crucial role in assessing the durability and reliability of various materials. Tensile strength is a measure of how much pulling or tensile load a material can bear before failure. It's essential for professionals in fields such as construction, automotive, aerospace, and manufacturing to understand both the mechanical properties of the materials they use and to have access to high-quality testing equipment.

Selecting a reliable tensile strength testing equipment supplier is pivotal for several reasons. This article explores some key considerations and the role of the right supplier in facilitating effective material testing.

Quality and Accuracy of Equipment

When considering a tensile strength testing equipment supplier, the quality and accuracy of their products are paramount. High-quality testing machines are designed to adhere to industry standards, ensuring precise and reproducible test results. Suppliers that invest in advanced technology and adhere to international testing standards are likely to provide equipment that meets the stringent requirements of various industries. Therefore, choosing a company with a solid reputation for engineering excellence should be a top priority.

Variety of Testing Solutions

Different applications require different testing solutions. A reputable supplier should offer a diverse range of tensile testing equipment, from basic machines for standard testing to advanced systems capable of conducting complex tests under various conditions. These may include universal testing machines, electronic extensometers, and fixtures designed for specific materials. By providing a comprehensive selection, suppliers can meet the unique needs of various clients, whether they are testing metals, polymers, or composites.

Technical Support and Service

Another crucial factor is the level of technical support and customer service offered by the supplier. Testing equipment can be complex, and issues may arise during operation. A reliable supplier will provide not just the equipment itself but also ongoing support to ensure that clients can operate the machines effectively. This may include installation, training, and routine maintenance services, ensuring that the equipment operates at peak performance and delivering accurate results over time.

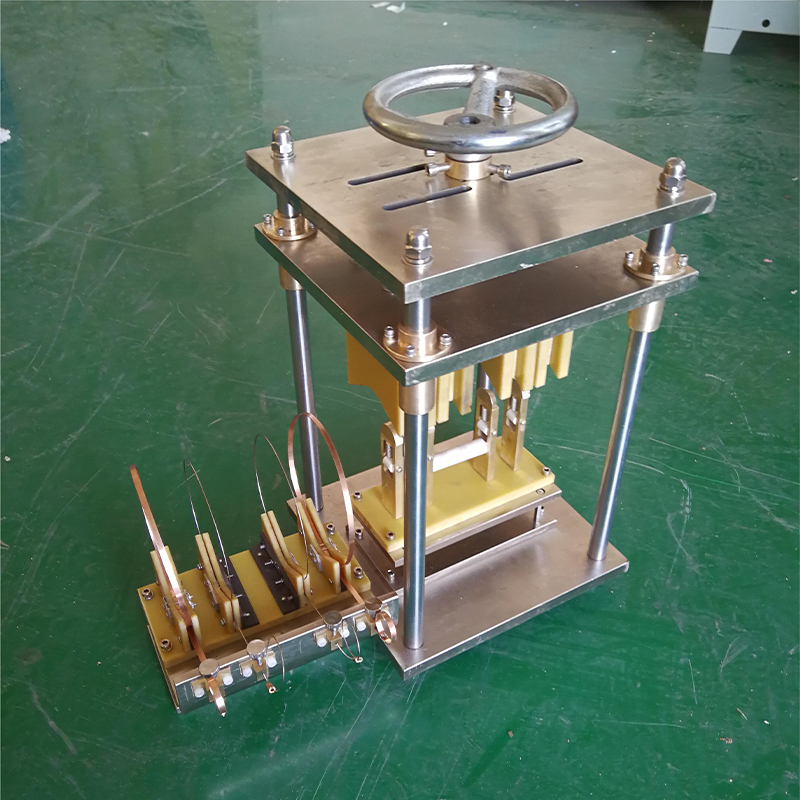

tensile strength testing equipment supplier

Calibration and Compliance

Calibration is a critical aspect of tensile strength testing. Regular calibration ensures that the equipment maintains its accuracy and complies with relevant standards. A good supplier will offer calibration services as part of their product support. This commitment to compliance not only enhances the reliability of test outcomes but also helps clients fulfill regulatory requirements, thus avoiding potential liabilities.

Customer Testimonials and Case Studies

Before selecting a supplier, it can be beneficial to review customer testimonials and case studies that demonstrate the effectiveness of their equipment. Engaging with previous clients can provide insights into the supplier’s reliability and the performance of their equipment in real-world applications. Additionally, looking for suppliers with a proven track record in your specific industry can help ensure that you’re selecting a partner who understands your needs and challenges.

Cost vs. Value

While cost is always a consideration, it should not be the sole deciding factor. Selecting the cheapest option may save money initially but could lead to higher costs in the long run due to equipment failure, inaccurate results, or poor customer support. When evaluating suppliers, consider the overall value, including quality, reliability, and support services, in addition to price.

Conclusion

In conclusion, the choice of a tensile strength testing equipment supplier can significantly impact the quality of material testing and the success of projects across multiple industries. By focusing on quality, variety, support, calibration, and overall value, professionals can partner with suppliers that not only meet their immediate testing needs but also contribute to their long-term success. Making informed decisions in this regard is crucial for ensuring that materials perform as expected in critical applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy