measure machine for cables

Measuring Machines for Cables Enhancing Precision and Efficiency

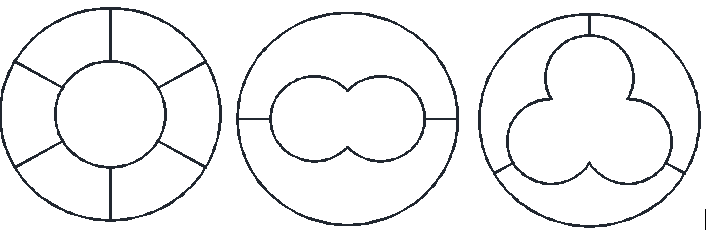

In today's rapidly evolving technological landscape, the demand for high-quality cables is more critical than ever. From telecommunications to power distribution, cables serve as the lifelines of modern infrastructure. As such, ensuring the integrity and reliability of these cables is paramount. This is where measuring machines for cables come into play, offering precision and efficiency in production and quality control.

Measuring Machines for Cables Enhancing Precision and Efficiency

One of the primary advantages of using measuring machines is their ability to provide real-time data. In a manufacturing environment, this means that any deviations from acceptable standards can be identified and rectified immediately, reducing the risk of defective products entering the market. Such immediate feedback not only enhances product quality but also minimizes waste and operational costs.

measure machine for cables

Moreover, the automation of measurement processes significantly boosts productivity. Traditional manual measurement methods can be time-consuming and prone to human error. In contrast, modern measuring machines are often equipped with advanced sensors and software that streamline the measurement process, allowing for high-speed inspections without compromising accuracy. This automation is particularly beneficial in high-volume production settings where consistency is key.

In addition to ensuring quality during the manufacturing process, measuring machines for cables are also vital in research and development phases. Engineers and designers can use these machines to test new materials and designs, gathering critical data that inform their decisions. This iterative process helps in innovating better, more efficient cable designs that meet the ever-growing demands of various industries.

Furthermore, as sustainability becomes a pressing concern globally, measuring machines can assist in assessing the environmental impact of cable production. By enabling accurate measurement of materials used and waste generated, manufacturers can adopt more sustainable practices. This not only contributes to corporate responsibility but also aligns with growing consumer expectations for environmentally friendly products.

In summary, measuring machines for cables play an essential role in the modern manufacturing landscape. By providing precise measurements, facilitating automation, and supporting research and development, these machines enhance the quality and reliability of cable products. As technology continues to advance, the importance of accurate measurement in ensuring product integrity will only grow, positioning measuring machines as indispensable assets in the cable manufacturing industry. Investing in sophisticated measuring technologies will ultimately lead to improved performance, customer satisfaction, and a stronger market presence for manufacturers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy