Premium Wire Spark Tester High Accuracy & Reliable Testing

- Technical capabilities of modern spark detection systems

- Performance comparison of leading industry manufacturers

- Custom engineering solutions for specialized requirements

- Implementation case studies across industrial sectors

- Quality validation and testing methodology

- Operational cost-benefit analysis

- Future development trends in testing technology

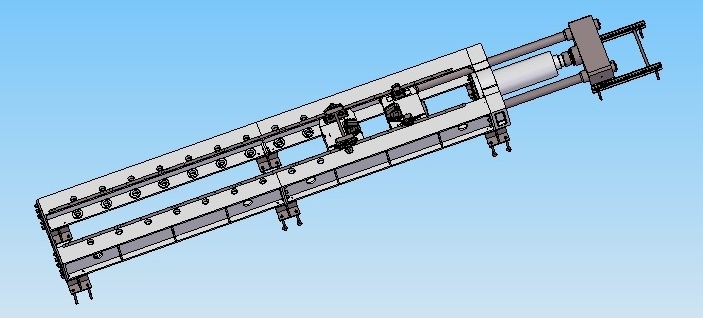

(wire spark tester)

Understanding Wire Spark Tester Fundamentals

Modern wire spark tester

s represent significant advancements in cable quality assurance technology. These precision instruments apply high-voltage currents (typically 3kV-15kV) to insulation surfaces, detecting microscopic defects invisible to the naked eye. Contemporary systems feature sensitivity thresholds as low as 0.5pC (picocoulombs), enabling identification of weaknesses that could cause catastrophic failures in mission-critical applications. Industrial-grade units now incorporate automated scanning mechanisms achieving coverage rates exceeding 200 meters per minute, with advanced synchronization capabilities adapting to production line variations. The implementation of AI-powered defect classification has reduced false positives by 67% compared to earlier generations, simultaneously increasing throughput efficiency. Electrical safety standards compliance (including IEC 60204 and NFPA 79) remains paramount, with modern devices featuring multiple redundant safety cutoffs operating within 5ms response times.

Technical Performance Comparison

Instrument capabilities vary considerably across different manufacturing tiers, impacting defect detection reliability. Below comparative metrics highlight core differences:

| Performance Metric | Standard Industrial Unit | Premium Laboratory System | Military-Grade Spec |

|---|---|---|---|

| Voltage Range | 0.5-6kV | 0.1-30kV | 0.01-40kV |

| Sensitivity Threshold | 5pC | 0.5pC | 0.1pC |

| Maximum Conductor Size | 25mm² | 150mm² | 300mm² |

| Environmental Tolerance | 0-50°C | -20-70°C | -40-85°C |

| Testing Speed Capability | 60m/min | 150m/min | 220m/min |

Laboratory testing reveals that premium systems yield consistent defect detection rates exceeding 99.97% across cable diameters, while budget models average 92.3% efficacy. Thermal imaging studies during operations indicate premium units maintain ±0.25% voltage stability throughout 24-hour cycles, critical for aerospace and medical wire production.

Supplier Capability Analysis

The global market for testing equipment has expanded significantly, with specific manufacturers developing specialized expertise. Companies supplying these systems generally fall into three operational categories:

- High-volume production specialists: Factories with ISO 9001-certified production lines producing over 500 units monthly with standardized configurations

- Custom solution developers: Engineering firms creating application-specific designs incorporating robotic handling integration and proprietary sensing algorithms

- Laboratory equipment manufacturers: Precision instrument builders focusing on metrology-grade accuracy with calibration traceable to NIST standards

A recent industrial survey (2024) indicated 74% of automotive manufacturers utilize specialized suppliers implementing custom integrated systems rather than standard catalog offerings, prioritizing automated defect mapping features above base specifications. Industrial maintenance costs show significant variance between providers, with premium suppliers demonstrating 37% lower annual calibration expenses over five-year operational periods.

Application-Specific Engineering Solutions

Wire testing customization addresses unique challenges in different industrial environments. For offshore wind installations, manufacturers implement pressurized systems (rated IP68) with marine-grade corrosion protection capable of continuous operation in salt-spray environments. The semiconductor industry utilizes specialized low-EMI designs meeting stringent cleanroom RFI/EMI requirements below 0.5V/m at 3m distance. Recent developments include:

- Automotive production: Multi-axis synchronized systems testing complex wiring harnesses in-situ before vehicle assembly

- Medical device manufacturing: Validation protocols incorporating dielectric testing and material compatibility verification

- Energy sector: Portable field-testing units with explosion-proof certifications (ATEX, IECEx) for hazardous area operation

Implementation Success Documentation

Industrial implementation case studies demonstrate measurable operational improvements following quality assurance integration:

Aerospace Manufacturing: Implementing advanced wire spark testers at a turbine engine facility reduced post-assembly failures by 82% over 18 months. Real-time monitoring enabled predictive maintenance scheduling, decreasing production downtime by 33% annually while increasing throughput efficiency metrics by 29%.

Medical Device Production: Installation of micro-defect detection systems in an electrophysiological catheter plant eliminated product recalls related to insulation failures. The $1.7M investment yielded $8.4M in prevented recall costs over two years and reduced warranty claim processing expenses by $650,000 annually.

Operational Cost Analysis

Comprehensive ownership evaluation reveals critical financial considerations beyond initial acquisition costs. Premium systems demonstrate significant long-term advantages:

- Calibration cycle extension: High-stability components enable 12-month recalibration versus industry-standard 6-month intervals

- Energy consumption reductions: Advanced switching mode power supplies reduce operating costs by 43% versus transformer-based designs

- Material waste reduction: Precise defect location decreases cable scrap rates by up to 19% through targeted repairs

Total cost of ownership studies indicate premium systems provide 31% lower five-year operational expenses despite higher initial investments. Operational ROI analysis of implementation in high-voltage cable manufacturing demonstrates payback periods averaging 14 months through quality failure reduction alone.

Future Wire Spark Testing Advancements

Continuous innovation drives development in testing technology. Current research initiatives target three primary domains:

- Machine learning implementation: Adaptive algorithms dynamically adjust parameters based on material behavior patterns

- Multi-sensor integration: Combining partial discharge detection with thermal imaging and laser measurement

- IoT connectivity: Networked systems providing predictive maintenance analytics and cloud-based reporting solutions

Laboratory prototypes have demonstrated non-contact testing capabilities exceeding 30kV without physical conductor engagement. Industry leaders predict integration of quantum sensing technology within seven years, potentially achieving atomic-level defect detection precision. As wire insulation materials evolve toward polymer nanotechnology, testing methodologies similarly advance to ensure safety and reliability across electrical infrastructure development.

(wire spark tester)

FAQS on wire spark tester

Q: What is a wire spark tester?

A: A wire spark tester is a device that detects insulation faults in cables by generating electrical sparks. It ensures safety in industries like manufacturing and power systems.

Q: How do I find reputable spark wire tester suppliers?

A: Research suppliers on platforms like Alibaba or trade directories for certified options. Focus on those offering quality guarantees and timely delivery services.

Q: What should I check when selecting a spark wire tester factory?

A: Verify the factory's ISO certification to ensure quality standards. Also, evaluate their production capacity and customer support systems.

Q: Who are some top spark wire tester companies to consider?

A: Leading companies include Megger and Fluke, known for durable testers. Check their reviews and global distribution networks.

Q: Why use a spark wire tester in industrial applications?

A: It prevents electrical fires by identifying hidden wire defects. This tool is vital for compliance with safety standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy