Testing Equipment for Constant Temperature Conductor Resistance Measurement

Understanding Conductor Resistance Constant Temperature Test Equipment

In the world of electrical engineering, the reliability and efficiency of conductive materials—such as wires and cables—are of paramount importance. One of the key parameters that determine the performance of these materials is their resistance. Consequently, accurate measurement of electrical resistance in conductors is vital, especially in applications that utilize these materials in high-stakes environments, such as power generation, transmission, and distribution.

To ensure that resistance measurements are accurate and reliable, engineers and technicians utilize Conductor Resistance Constant Temperature Test Equipment. This specialized equipment is designed to measure the resistance of conductive materials under controlled temperature conditions, effectively eliminating variables that could lead to inaccurate results.

The Importance of Temperature Control

The resistance of conductive materials is significantly influenced by temperature. According to the principles of physics, the resistance of a conductor increases as temperature rises. This characteristic poses a challenge in measuring resistance, as variations in ambient temperature can lead to inconsistent results. Therefore, the ability to maintain a constant temperature during testing is crucial for obtaining reliable data.

Constant temperature testing is essential for several reasons

1. Accuracy By controlling the temperature, the equipment ensures that the resistance readings are unaffected by environmental fluctuations, allowing for precise measurements.

2. Consistency Repeating tests at a constant temperature ensures that results will be comparable across different tests and specimens, leading to more reliable data for application in design and quality control.

3. Standardization Engineers can adhere to industry standards and specifications more readily when testing conditions are standardized, facilitating better communication and data sharing across projects and companies.

Components of Conductor Resistance Constant Temperature Test Equipment

Typically, this testing equipment comprises several key components that work together to facilitate accurate measurement

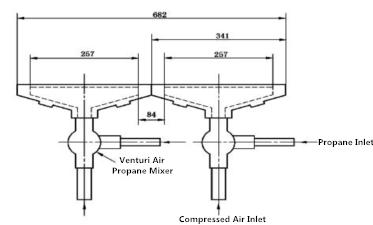

conductor resistance constant temperature test equipment

1. Temperature Control System This system maintains the specimen at a specified temperature, often utilizing thermostats and heating or cooling elements, ensuring that the test environment remains stable throughout the duration of the measurement.

2. Resistance Measuring System This includes high-precision instruments such as micro-ohmmeters, which offer excellent accuracy in measuring low resistance values common in conductive materials.

3. Data Acquisition System Many modern setups include a digital interface for data logging and analysis. This system can store measurements, allowing engineers to track changes over time and generate reports efficiently.

4. Test Fixtures These are designed to hold the conductor securely during testing and often come equipped with thermocouples or other temperature-sensing devices to monitor conditions closely.

5. Power Supply Adequate and stable power supply systems enable the accurate application of current during resistance measurements, which is critical in conforming to standardized testing protocols.

Applications and Benefits

The applications of conductor resistance constant temperature test equipment are vast and varied. It is used extensively in industries including

- Electrical Utilities For testing and maintenance of transmission and distribution lines. - Telecommunications To ensure the integrity and performance of cable infrastructures. - Manufacturing In the production of electrical components, ensuring quality control through rigorous testing.

The benefits of utilizing this technology are numerous. It promotes safety and efficiency in electrical systems by ensuring that components operate as intended under specified conditions, thereby reducing the risk of failure. Additionally, it enhances the lifespan of conductive materials by identifying issues before they escalate, enabling proactive maintenance strategies.

Conclusion

Conductor resistance constant temperature test equipment plays a crucial role in modern electrical engineering. By ensuring accurate and reliable resistance measurements while controlling for temperature fluctuations, this equipment supports the development, assessment, and maintenance of electrical systems across various applications. As technology continues to evolve, these testing methodologies will remain integral in maintaining the efficiency and safety of the electrical infrastructure that our society relies on. In an age where precision and reliability are paramount, investing in high-quality measurement equipment is not just an option; it is a necessity.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy