Spark Testing Equipment Manufacturing Facility Overview

The Role of Spark Test Machine in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, ensuring the quality and reliability of products has become paramount. One of the essential tools that have emerged to enhance quality assurance is the spark test machine. This device plays a critical role in the factory setting, particularly in assessing the insulation quality of electrical components and systems.

Understanding Spark Testing

The spark test machine operates by applying a high voltage across the insulation of electrical parts. The primary aim is to detect any weaknesses or defects in the insulation materials, which could lead to short circuits or equipment failure. During the spark test, the machine generates a controlled high-voltage spark that jumps through any potential gaps in the insulation. If the insulation is intact and functioning as intended, the spark will not bridge the gap. Conversely, if there is a fault, the spark will create a visible discharge, signaling the presence of a defect.

Importance of Spark Testing in Manufacturing

Quality assurance is crucial in every manufacturing process, especially in industries that rely heavily on electrical components, such as automotive, aerospace, and electronics. The consequences of poor insulation can be catastrophic, ranging from equipment failures to potential safety hazards for users. By implementing spark testing as part of the production line, manufacturers can ensure that each component meets the necessary standards before it is assembled into a final product. This proactive approach minimizes the likelihood of defects that could lead to product recalls or warranty claims, ultimately protecting the brand's reputation and financial stability.

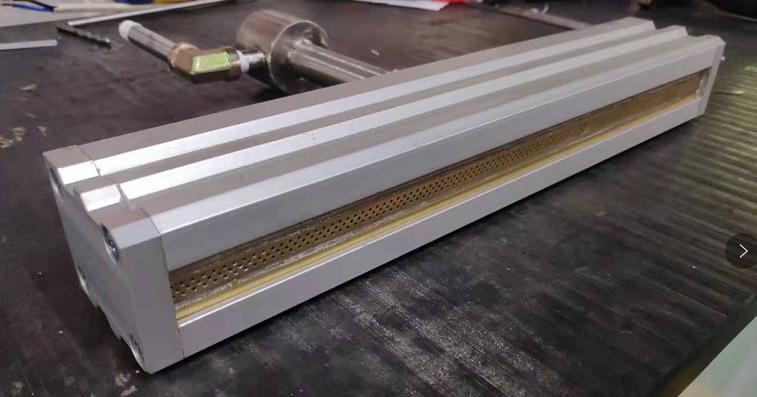

spark test machine factory

Efficiency and Reliability

The spark test machine not only enhances safety but also improves operational efficiency. Traditional testing methods can be time-consuming and may not provide precise results. In contrast, spark testing is relatively quick, allowing manufacturers to conduct quality checks without significant delays in the production schedule. Moreover, modern spark test machines are equipped with advanced features such as automatic data logging and analysis, enabling manufacturers to track trends over time and identify potential issues before they escalate.

Compliance with Standards

In addition to quality control, using a spark test machine helps manufacturers comply with industry standards and regulations. Many sectors have specific requirements regarding electrical safety and insulation performance. Employing a spark testing protocol demonstrates a commitment to adhering to these standards, which is often a prerequisite for obtaining certifications from regulatory bodies. This compliance is not only vital for legal reasons but also serves as a market differentiator, instilling confidence in customers regarding the reliability and safety of the products they purchase.

Conclusion

In conclusion, the spark test machine is an invaluable asset in the manufacturing process, ensuring the integrity and safety of electrical components. By detecting insulation defects early, manufacturers can mitigate risks, enhance product quality, and maintain compliance with industry standards. As technology continues to advance, the capabilities of spark test machines are likely to expand further, incorporating features like artificial intelligence for predictive analysis and smarter quality control processes. Embracing such innovations will be essential for manufacturers that aim to thrive in an increasingly competitive landscape, ultimately leading to safer products and a more sustainable manufacturing future.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy