Cable Crosslinking Equipment Manufacturer for Enhanced Connectivity Solutions and Quality保障

Cable Crosslinking Machine Factory Innovating the Future of Cable Production

In today’s rapidly evolving technological landscape, the demand for high-quality cables is at an all-time high. From telecommunications to power distribution, cables play a crucial role in ensuring connectivity and functionality. One of the key innovations revolutionizing the cable manufacturing process is the cable crosslinking machine. This article delves into the significance of cable crosslinking machines, their manufacturing process, and the critical role that factories dedicated to this technology play in the industry's evolution.

What is Cable Crosslinking?

Cable crosslinking refers to the process of chemically or thermally bonding the polymer chains in cable insulation materials, transforming them into a three-dimensional network. This enhances their thermal stability, mechanical strength, and resistance to environmental factors, ultimately increasing the lifespan and reliability of cables. Crosslinked polyethylene (XLPE) cables are prevalent in electrical applications due to their superior performance characteristics.

The Role of Cable Crosslinking Machines

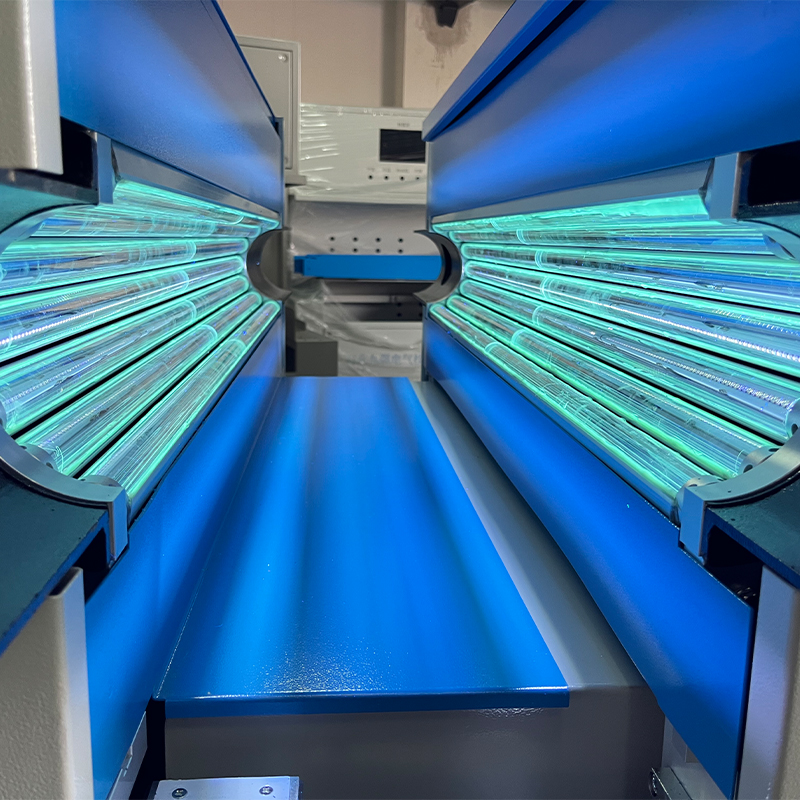

Cable crosslinking machines are specialized equipment designed to facilitate this complex process. They utilize different methods, such as irradiation, chemical crosslinking, or heat, to achieve the desired polymer structure. These machines allow manufacturers to produce cables that meet stringent industry standards while optimizing production efficiency.

Manufacturing Process Overview

The manufacturing process in a cable crosslinking machine factory typically includes several steps

1. Material Preparation Raw materials, including various types of polymers and additives, are sourced and prepared for the crosslinking process. This stage is critical as the choice of materials significantly influences the final product's performance.

2. Extrusion The prepared materials are fed into an extruder, which melts and homogenizes them. The extruded material is then shaped into the desired cable form, often as insulation or sheathing.

cable crosslinking machine factory

3. Crosslinking This is the crucial stage where the actual crosslinking occurs. Depending on the machine's design, this can be achieved through different methods. For instance, irradiation crosslinking employs electron beams to create crosslinked structures, while chemical methods use crosslinking agents that react under heat.

4. Cooling and Stabilization After the crosslinking process, the cables must be cooled and stabilized to ensure dimensional integrity and resist deformation. This involves passing the cables through a cooling chamber or water bath.

5. Quality Control and Testing Once the cables are produced, they undergo rigorous testing to ensure they meet various performance criteria such as tensile strength, elongation, and thermal resistance. Factories typically have dedicated testing laboratories staffed with engineers and technicians who ensure the cables comply with international standards.

Importance of Crosslinking Machine Factories

The establishment of dedicated cable crosslinking machine factories represents a significant advancement in cable manufacturing. These factories are integral to the industry's growth, as they ensure that production methods can keep pace with increasing demand from sectors like renewable energy, telecommunications, and electrical infrastructure.

1. Innovation and Technology Factories that specialize in cable crosslinking machine production invest heavily in research and development. They continuously innovate to improve the efficiency, safety, and environmental sustainability of their machines. This not only benefits manufacturers but also reduces the carbon footprint associated with cable production.

2. Economic Growth As demand for advanced cable solutions grows, so does the need for skilled labor and production facilities. Cable crosslinking machine factories contribute significantly to local economies by creating jobs and fostering a skilled workforce.

3. Global Market Reach With the rise of global supply chains, factories that produce high-quality cable crosslinking machines are positioned to supply manufacturers worldwide. This enhances competition and encourages the sharing of best practices across borders.

Conclusion

The cable crosslinking machine factory is at the forefront of a technological revolution in cable manufacturing. Through innovative processes and advanced machinery, these factories enhance the performance and reliability of cables that are vital for modern infrastructure. As technology continues to advance, the importance of cable crosslinking machines and their production facilities will undoubtedly grow, offering exciting opportunities for both manufacturers and consumers alike. The future of cable manufacturing lies in the hands of these pioneers, driving the industry toward greater efficiency and sustainability.

-

High-Precision Digital Profile Projector for Advanced Measurement

NewsApr.10,2025

-

High-Precision Tensile Testing Machine for Reliable Material Strength Analysis

NewsApr.10,2025

-

High-Precision Resistance Tester for Accurate Electrical Measurements

NewsApr.10,2025

-

Enhance Accuracy with a High-Precision Resistance Measurement Fixture

NewsApr.10,2025

-

Advanced Cable Crosslinking Equipment for High-Performance Cable Manufacturing

NewsApr.10,2025

-

Advanced Cable Combustion Testing Machine for Reliable Fire Safety Assessment

NewsApr.10,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy