Factory for High-Quality Tensile Testing Grips and Accessories Manufacturing Solutions

Understanding Tensile Tester Grips A Guide to Their Importance in Material Testing

In the realm of material testing, tensile testers serve as crucial instruments for evaluating the mechanical properties of various materials. Among the essential components of these testing systems are grips, which play a pivotal role in ensuring accurate and reliable results. This article explores the significance of tensile tester grips, their types, and their importance to the testing process.

Tensile testing, inherently, involves subjecting a material to a controlled tensile force to measure how it responds to stretching until failure. The primary objective is to determine key properties such as tensile strength, elongation, yield strength, and modulus of elasticity. To achieve accurate and repeatable results, the way the material is secured and pulled during the test is of paramount importance—this is where grips come into play.

Types of Tensile Tester Grips

Tensile tester grips come in various designs, each suitable for specific testing requirements

. The two primary categories are mechanical grips and pneumatic grips.1. Mechanical Grips These grips operate through a clamping mechanism that tightly holds the specimen. They are straightforward in design and often used for testing metals or materials that can withstand high forces without slipping. Mechanical grips often incorporate features such as adjustable jaws that can accommodate different specimen sizes and shapes.

2. Pneumatic Grips Instead of a manual clamping mechanism, pneumatic grips utilize air pressure to secure specimens. These grips provide a more uniform holding force and are particularly advantageous for delicate or soft materials that might get damaged by excessive clamping pressure. Their ability to quickly adapt to varying specimen sizes makes them a popular choice in settings that require high throughput.

Significance of Grips in Material Testing

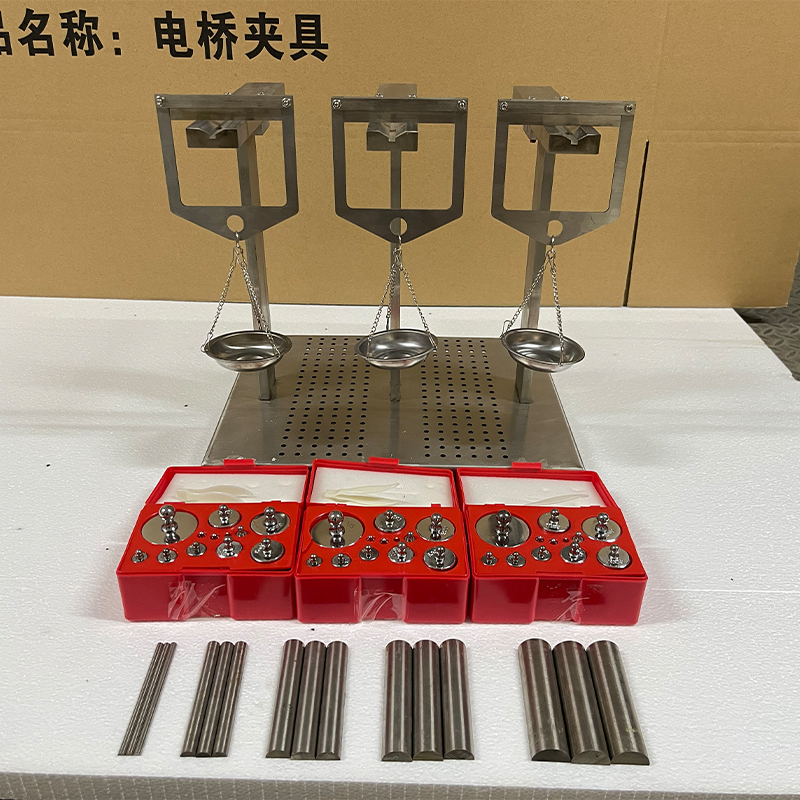

tensile tester grips factory

The effectiveness of tensile testing hinges significantly on the performance of the grips. A firm and consistent hold ensures that the specimen does not slip during the test, generating reliable data. Any movement can lead to inaccuracies in measurements, resulting in erroneous conclusions about a material's properties.

Moreover, the geometry and material of the grips are also critical. Grips designed with special coatings can enhance friction, ensuring a stronger hold on the specimen, which is particularly important for slippery materials such as plastics or rubbers. The choice of grip should always consider the type of material being tested to avoid damaging the specimen or affecting test outcomes.

Quality Control and Standardization

In industries where material performance is vital, such as aerospace, automotive, and construction, standardized testing is crucial. Grips must comply with testing standards set by organizations like ASTM and ISO. These standards dictate not only the design and material composition of grips but also specify testing procedures to guarantee that results across different laboratories are consistent and reliable.

Manufacturers of tensile tester grips play an essential role in this process. They focus on producing high-quality grips that can withstand rigorous testing environments while maintaining precision. Advances in technology have led to the development of grips with improved ergonomics, better material selection, and enhanced functionality, catering to the evolving needs of various industries.

Conclusion

In conclusion, while tensile testers are primarily recognized for their capability to measure the properties of materials, the grips used in these tests are equally important. They ensure that materials are held securely and tested accurately under tension. As technology progresses, the development of innovative grip designs will continue to enhance the effectiveness of tensile testing, leading to improved materials and, ultimately, safer and more reliable products. Understanding the nuances of tensile tester grips is essential for anyone involved in the field of material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy