conductor resistance test machine exporter

Understanding and Exploring the Conductor Resistance Test Machine An Exporter's Perspective

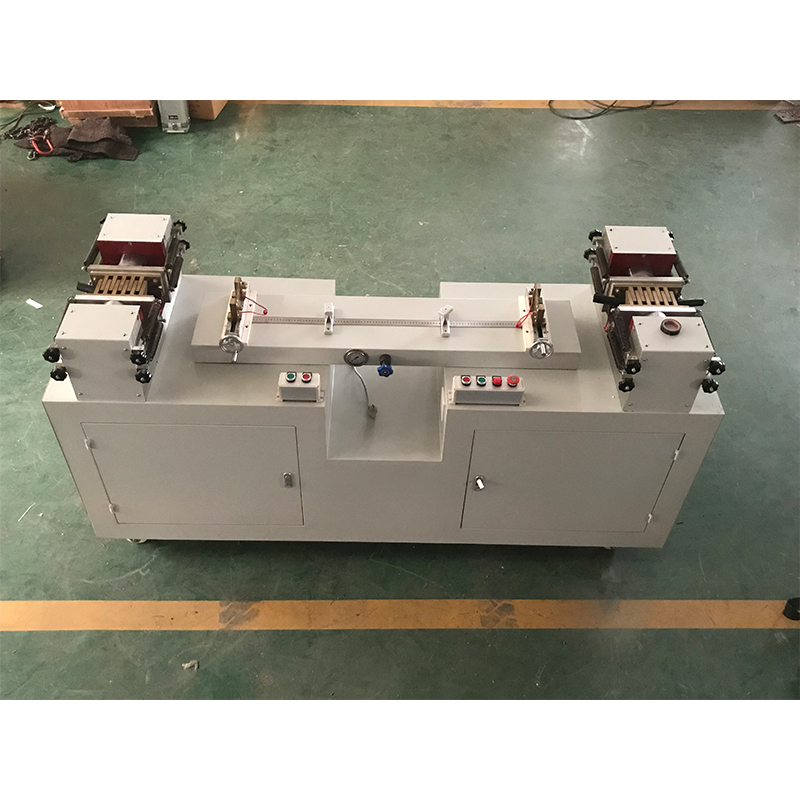

The conductor resistance test machine plays a pivotal role in the electrical industry, ensuring that power transmission and distribution systems operate without impediments. As the demand for reliable and efficient electrical systems skyrockets, so does the need for testing equipment that guarantees the integrity of electrical conductors. In this context, the conductor resistance test machine emerges as a crucial exporter’s product, catering to markets worldwide.

What is a Conductor Resistance Test Machine?

A conductor resistance test machine is specifically designed to measure the electrical resistance of conductors, which may include copper, aluminum, or alloy cables. Accurate measurement of resistance is vital because it allows technicians to assess the quality of the conductor, ensuring that it meets industry standards and performance criteria. High resistance can indicate poor connections, inferior materials, or manufacturing defects, which can lead to overheating, energy loss, and equipment failure.

Importance of the Conductor Resistance Test

The importance of testing conductor resistance is underscored by several factors. First, it ensures compliance with industry standards such as ASTM and IEC. Testing is not only a regulatory requirement but also a best practice to ensure that electrical conductors can handle the intended load without excessive heat generation. Consequently, it enhances the safety and longevity of electrical systems.

Moreover, conductor resistance tests are crucial during the commissioning phase of new installations, as well as for regular maintenance of existing systems. A periodic resistance check can identify issues before they escalate into serious problems, thereby protecting investments in infrastructure and minimizing downtime.

Key Features of Conductor Resistance Test Machines

Modern conductor resistance test machines come equipped with advanced technology, making them user-friendly and efficient

. Key features often include1. High Precision Measurement Utilizing four-wire (Kelvin) methods to eliminate errors from lead and contact resistances, these machines provide highly accurate readings.

2. Wide Range of Measurement They can measure a vast range of resistances, accommodating various conductor types and sizes, which is essential for diverse applications.

conductor resistance test machine exporter

3. Data Reporting and Analysis Many machines are equipped with data logging capabilities, allowing for easy analysis and trend assessment over time. This feature is invaluable for ongoing maintenance and compliance documentation.

4. Portability Many models are designed to be compact and lightweight, which enables field testing. This makes it convenient for technicians to carry out tests on-site without hindrance.

5. User-Friendly Interfaces Intuitive interfaces and clear displays make operation straightforward, even for less experienced users, thereby reducing training time.

Export Opportunities in the Global Market

The demand for conductor resistance test machines is steadily increasing in several regions, driven by the expansion of renewable energy infrastructure, growth in electric vehicle charging stations, and modernization of power grids. As an exporter, this presents a lucrative opportunity to offer high-quality testing solutions to contractors, electrical utilities, and manufacturers.

When considering entering the export market for conductor resistance test machines, it’s essential to understand the regulatory requirements of the target country. Compliance with local standards will not only enhance product acceptance but also strengthen the brand’s reputation in new markets.

Challenges and Considerations

While the export potential is significant, challenges exist. Heavy competition from established manufacturers and the need for continuous innovation can pose hurdles. Moreover, navigating logistics, customs, and tariffs are vital for ensuring timely delivery and maintaining cost-effectiveness. Therefore, building strong relationships with local distributors and end-users can greatly enhance market penetration.

Conclusion

As the world shifts toward a more electrified future, the importance of reliable electrical testing equipment can’t be overstated. The conductor resistance test machine stands at the forefront of ensuring electrical integrity and safety across many applications. As an exporter, understanding the machine's functionality, market demands, and compliance intricacies will allow businesses to tap into this growing market effectively. Investing in quality testing solutions not only fosters innovation in electrical design but also enhances operational efficiency, safety, and sustainability in energy consumption.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy