Advanced Cable Crosslinking Equipment for High-Performance Cable Manufacturing

Efficient and precise crosslinking technology is essential for enhancing the durability, heat resistance, and mechanical strength of cable insulation. Our cutting-edge Cable Crosslinking Equipment is designed to deliver superior crosslinking results, ensuring optimal cable performance for various industrial applications.

Differences Between UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine and Traditional UV Equipment

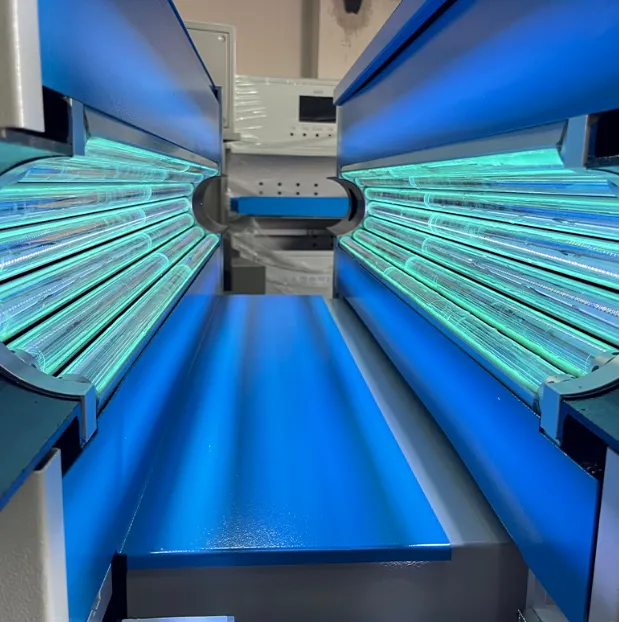

The UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine represents a revolutionary advancement in crosslinking technology compared to traditional UV equipment. Unlike conventional systems that rely on mercury lamps, this machine utilizes high-efficiency LED ultraviolet radiation to achieve precise and uniform crosslinking of polyolefin materials.

Traditional UV crosslinking equipment generates excessive heat, leading to energy wastage and material degradation. In contrast, the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine operates at lower temperatures, reducing thermal damage while enhancing the consistency of the crosslinking process.

Another key advantage is its longer lifespan and lower maintenance costs. Mercury-based UV lamps degrade over time, requiring frequent replacements and increasing downtime. The UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine eliminates this issue by offering a stable, long-lasting UV source that maintains efficiency over extended operational periods.

The Environmental Impact and Sustainability of UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine

Sustainability is a major focus in modern cable manufacturing, and the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine aligns perfectly with eco-friendly production practices.

Traditional UV systems contribute to environmental pollution due to the hazardous mercury content in their lamps. By switching to LED-based crosslinking, the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine eliminates mercury usage, making it a safer and more sustainable choice for manufacturers.

Additionally, this machine significantly reduces energy consumption. Traditional UV lamps require high power levels and generate excess heat, leading to increased cooling costs. The UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine minimizes energy waste by producing targeted UV wavelengths with higher efficiency, reducing carbon footprints without compromising performance.

By adopting this advanced crosslinking technology, businesses not only improve production efficiency but also contribute to a greener, more sustainable future.

UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine: What Factors Affect the Final Crosslinking Effect?

Achieving optimal crosslinking performance depends on multiple factors, all of which are carefully controlled in the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine to ensure maximum efficiency.

The intensity and wavelength of UV radiation are critical. Unlike traditional UV systems with fluctuating output, this machine delivers precise and stable UV exposure, ensuring uniform crosslinking across polyolefin materials.

Material composition also plays a key role. Different formulations of polyolefin require specific UV dosages for effective crosslinking. The UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine is equipped with adjustable settings, allowing manufacturers to customize the process according to material properties.

Production speed influences the final crosslinking effect as well. If the processing speed is too high, exposure time may be insufficient for complete crosslinking. This machine is designed to provide optimal exposure at various production rates, ensuring consistent quality across all output levels.

Upgrade Your Manufacturing with Advanced Cable Crosslinking Equipment

For manufacturers seeking efficient, eco-friendly, and high-performance crosslinking solutions, our Cable Crosslinking Equipment is the ultimate choice. The innovative UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine outperforms traditional UV systems by providing precise control, energy efficiency, and long-term reliability.

By integrating this cutting-edge technology into your production line, you can achieve superior cable durability, reduce operational costs, and support sustainable manufacturing practices. Invest in the future of cable crosslinking with the most advanced equipment available.

UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine FAQs

How does the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine differ from mercury-based UV systems?

Unlike traditional mercury-based UV equipment, the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine uses LED technology, which offers better energy efficiency, longer lifespan, and eliminates toxic mercury waste.

What are the environmental benefits of the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine?

This machine reduces energy consumption, eliminates mercury usage, and lowers carbon emissions, making it an eco-friendly choice for sustainable manufacturing.

Can the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine be adjusted for different materials?

Yes, it features customizable UV intensity settings, allowing manufacturers to fine-tune the crosslinking process for different polyolefin compositions.

What factors affect the crosslinking efficiency of this machine?

Key factors include UV intensity, material composition, and production speed. The machine ensures stable and uniform exposure for optimal crosslinking results.

Why should manufacturers switch to the UV-LED Ultraviolet Radiation Polyolefin Crosslinking Machine?

Switching to this machine improves production efficiency, reduces maintenance costs, enhances cable durability, and supports environmentally friendly manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NoviceJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NoviceJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NoviceJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NoviceJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NoviceJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NoviceJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy