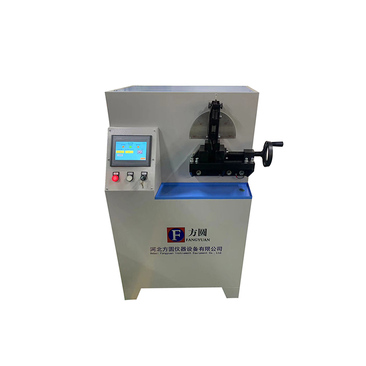

tensile tester astm d412 company

Understanding ASTM D412 Importance of Tensile Testing for Rubber Materials

In the realm of material testing, the ASTM D412 standard plays a pivotal role, particularly for organizations working with rubber and elastomeric materials. Developed by ASTM International, a globally recognized leader in the development and delivery of voluntary consensus standards, ASTM D412 outlines the procedures for testing the tensile properties of rubber, providing crucial insights into the performance and longevity of rubber products.

What is ASTM D412?

ASTM D412 is the standard test method for the tensile properties of rubber and thermoplastic elastomers. This standard specifies the apparatus, materials, and procedures necessary for determining the tensile strength, elongation at break, and other important mechanical properties of rubber samples. These properties are essential indicators of the material’s performance under stress and can significantly influence the safety, efficiency, and durability of rubber products.

The Importance of Tensile Testing

Tensile testing is critical for various industries that employ rubber materials, from automotive and aerospace to medical devices and consumer goods. Understanding the tensile properties of rubber is vital for ensuring that products can withstand operational stresses, environmental conditions, and long-term usage without failing.

1. Quality Control ASTM D412 testing helps manufacturers maintain quality control over their rubber products. By consistently measuring tensile properties, companies can ensure that their materials meet the specified performance criteria and regulatory requirements.

2. Material Selection The outcomes from tensile tests inform engineers and designers about the most suitable materials for specific applications. For example, the choice between different rubber compounds can depend on the type of stress the material will encounter in its end-use scenario.

3. Failure Analysis When rubber products fail or exhibit unexpected behavior, ASTM D412 testing can be instrumental in analyzing the cause of the failure. By comparing the tensile properties of failed samples to standard values, engineers can determine if the materials were properly selected and whether manufacturing processes adhered to specified standards.

Key Outcomes of ASTM D412 Testing

tensile tester astm d412 company

The findings from ASTM D412 testing typically provide vital information, including

- Tensile Strength This metric indicates the maximum amount of tensile (pulling) stress that a material can withstand before failure.

- Elongation at Break This measures how much a rubber sample can stretch before breaking. It is expressed as a percentage of the original length and is a critical factor in assessing the flexibility of the material.

- Modulus of Elasticity This parameter helps to evaluate the stiffness of rubber materials, indicating how much they will deform under a given stress.

Choosing a Competent Testing Lab

For companies pursuing ASTM D412 testing, selecting a reputable testing laboratory is imperative. A competent lab should be accredited and adhere strictly to ASTM standards to ensure accurate and reliable results. Furthermore, labs with advanced testing equipment and experienced personnel can significantly enhance the quality of testing services provided.

The results obtained from such tests not only aid in product development but also support compliance with regulatory standards, thereby enhancing customer satisfaction and trust in the brand.

Conclusion

In conclusion, ASTM D412 testing of rubber materials is an essential procedure for manufacturers and suppliers in various industries. As the demand for high-performance rubber products continues to grow, the importance of understanding and applying tensile properties cannot be overstated. By adhering to ASTM D412 standards, industries can ensure that their rubber products are not only safe and reliable but also capable of withstanding the rigors of their intended applications. For any company involved in the manufacturing or utilization of rubber products, investing in tensile testing is a step toward greater quality assurance and innovation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy