uv irradiation cross-linked equipment manufacturer

The Role of UV Irradiation in Cross-linked Equipment Manufacturing

Ultraviolet (UV) irradiation has emerged as a critical technology in the manufacturing of cross-linked equipment, offering numerous advantages in terms of efficiency, durability, and versatility. This innovative method is at the forefront of materials science, especially in industries such as automotive, electronics, and consumer goods. Manufacturers harness the power of UV light to enhance material properties and optimize production processes, making cross-linked equipment more reliable and sustainable.

Understanding UV Irradiation and Cross-Linking

At its core, cross-linking refers to the process of chemically bonding polymer chains together, which enhances the overall strength and stability of the material. This technique is particularly valuable in creating thermosetting plastics and elastomers, which are widely used in various applications. UV irradiation serves as an effective method for initiating cross-linking reactions, leveraging the energy emitted by UV light to create reactive species that promote the bonding process.

The main advantage of UV cross-linking lies in its speed and efficiency. Traditional cross-linking methods, such as heat curing, often require extensive time and energy consumption. In contrast, UV curing can occur in seconds, with the intense light activating the curing agents in the polymer. This rapid processing not only expedites production timelines but also reduces energy costs, making it a more environmentally friendly option.

Innovative Applications of UV Cross-linked Equipment

The versatility of UV irradiation cross-linked equipment has paved the way for its application across various industries. In the automotive sector, for instance, UV-cured coatings provide superior resistance to scratches, chemicals, and UV degradation. These properties enhance the longevity and aesthetic appeal of vehicles, leading to increased customer satisfaction and brand loyalty.

In electronics, UV cross-linked materials are crucial in producing circuit boards and encapsulants. The precision and reliability of UV curing significantly improve the performance and durability of electronic devices, which are essential in today’s technology-driven world. Moreover, the ability to create lightweight and robust components contributes to the overall efficiency and functionality of electronic products.

uv irradiation cross-linked equipment manufacturer

Consumer goods manufacturers also benefit from UV cross-linking technology. Products such as adhesives, paints, and inks that undergo UV curing exhibit improved adhesion, flexibility, and resistance to wear and tear. This ensures that consumer products remain functional and appealing throughout their lifespan, thereby enhancing market competitiveness.

Selecting a UV Irradiation Equipment Manufacturer

As the demand for UV irradiation cross-linked equipment continues to rise, selecting a reliable manufacturer becomes paramount. Companies should look for manufacturers that not only provide high-quality UV curing equipment but also offer comprehensive support services, including installation, maintenance, and training.

It is essential to assess the manufacturer's experience and reputation in the industry. A well-established company usually has a proven track record of delivering innovative solutions tailored to specific customer needs. Additionally, manufacturers that prioritize research and development are more likely to stay ahead of market trends, ensuring that customers receive the latest advancements in UV curing technology.

Furthermore, companies must consider the range of products and services offered by a manufacturer. A robust portfolio that includes various UV curing systems, such as conveyorized systems, handheld units, and customized solutions, indicates the manufacturer's versatility and ability to cater to diverse production requirements.

Conclusion

In conclusion, the integration of UV irradiation in cross-linked equipment manufacturing represents a significant advancement in materials technology. This method enhances the performance, durability, and efficiency of various products across multiple industries. As manufacturers increasingly adopt UV curing processes, the selection of the right equipment and supplier becomes critical to maintaining competitiveness in the evolving market. Investing in high-quality UV irradiation technology will not only improve product quality but also contribute to sustainable manufacturing practices, aligning with modern environmental standards and consumer expectations.

-

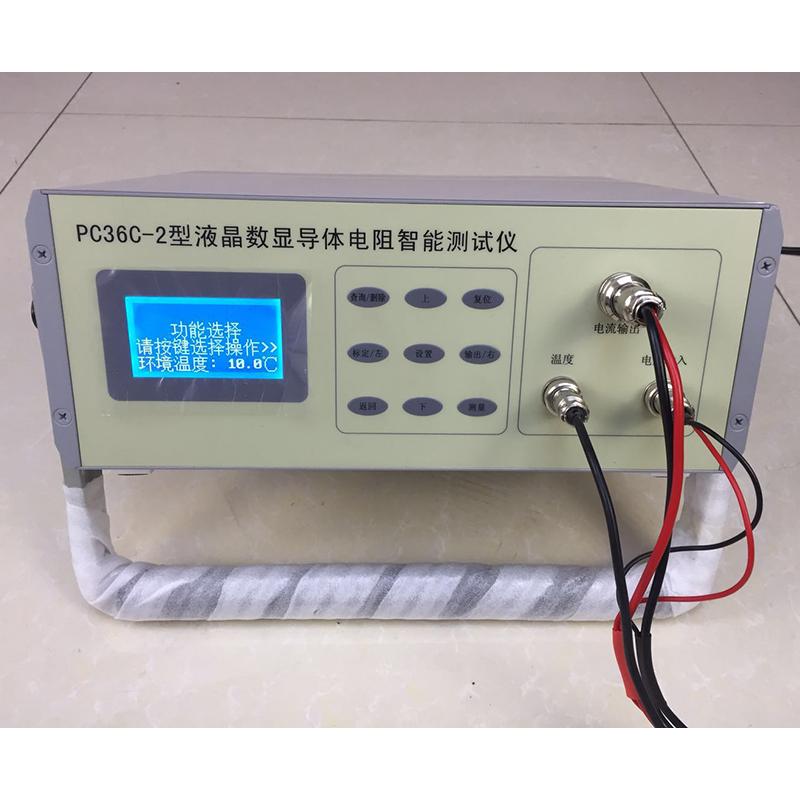

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy