Assessing Electrode Resistivity Through Comprehensive Factory Testing Methods and Standards

Understanding Electrode Resistivity Tests in Industrial Settings

In industrial applications, the measurement of electrode resistivity is critical for ensuring the efficiency and reliability of electrical systems. Electrode resistivity tests help evaluate the performance of electrodes used in various electrical and electrochemical processes, ranging from corrosion prevention to energy storage in batteries. Understanding the principles, methods, and implications of these tests is essential for manufacturers and engineers alike.

The Importance of Electrode Resistivity

Electrode resistivity refers to the electrical resistance of an electrode material, which directly affects its conductivity and performance in a given application. High resistivity can lead to energy losses, reduced efficiency, and potential failures in electrical systems. Therefore, conducting resistivity tests during the manufacturing process is vital to ensure that electrodes meet the specified performance criteria.

The resistivity of materials is influenced by several factors, including temperature, material composition, and manufacturing processes. For example, impurities or defects in the electrode material can significantly increase resistivity, leading to inefficient operation. Thus, understanding the properties of the materials used and how they are processed is crucial for optimizing electrode performance.

Testing Methods

There are several methods used to determine the resistivity of electrodes, each with its own advantages and limitations. One of the most common methods is the four-point probe technique, which involves placing four probes in contact with the electrode material. Current is passed through the outer probes, while voltage is measured across the inner probes. This method minimizes the effects of contact resistance, providing a more accurate measurement of the intrinsic resistivity of the material.

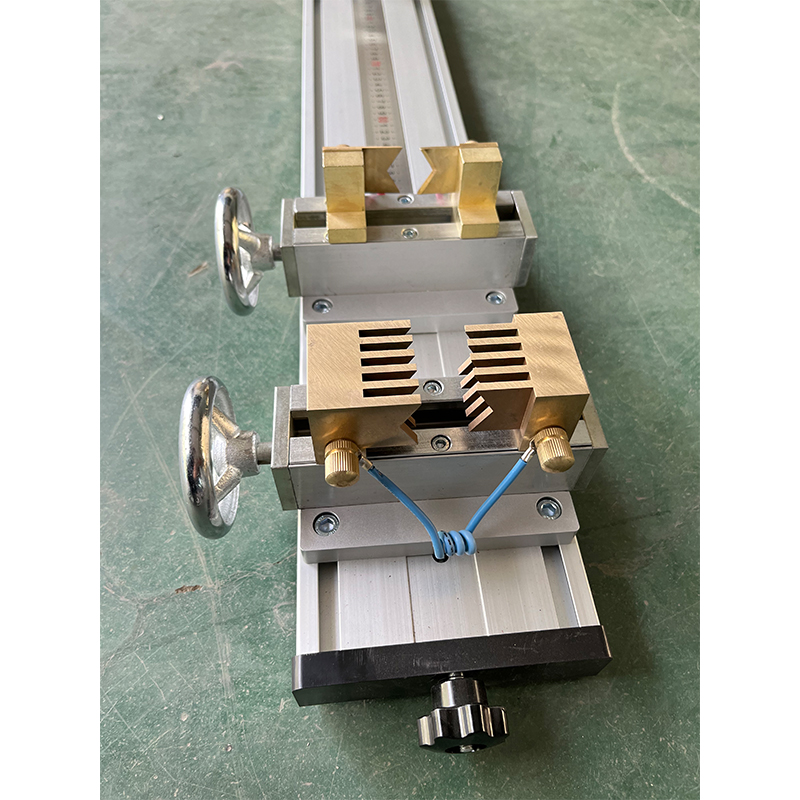

electrode resistivity tests factory

Another widely used method is the two-point probe measurement, which is simpler but can be affected by contact resistance, especially in high-resistivity materials

. When using the two-point method, it’s critical to ensure that the probes are properly contacting the material to obtain reliable measurements.Moreover, modern advancements in technology have also allowed for the development of portable resistivity meters, making it easier for factories to conduct on-site testing. This not only enhances the efficiency of quality control processes but also reduces downtime associated with off-site testing.

Industry Applications

Electrode resistivity tests have a broad range of applications across various industries. In the field of electrochemistry, for instance, the performance of electrodes in batteries and fuel cells is significantly influenced by their resistivity. Low resistivity electrodes can lead to higher energy efficiencies and longer operational lifetimes, which are crucial for consumer electronics and electric vehicles.

In the context of corrosion prevention, resistivity measurements can help determine the effectiveness of cathodic protection systems. These systems protect metal structures from corrosion by ensuring that the current is adequately distributed across the surface of the electrode. Maintaining optimal resistivity levels is vital for these systems to function correctly.

Conclusion

Electrode resistivity tests play a pivotal role in ensuring the quality and reliability of electrical components across multiple sectors. By employing effective testing methods and understanding the properties of the materials used, manufacturers can enhance the performance of their products, reduce costs, and extend the lifespan of their systems. As technology advances, the ability to conduct real-time resistivity measurements is expected to improve, paving the way for even more efficient and reliable industrial applications. Overall, keeping a close eye on electrode resistivity is essential for optimizing performance and maintaining the integrity of electrical systems in any manufacturing environment.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy