Jan . 10, 2025 12:51

Back to list

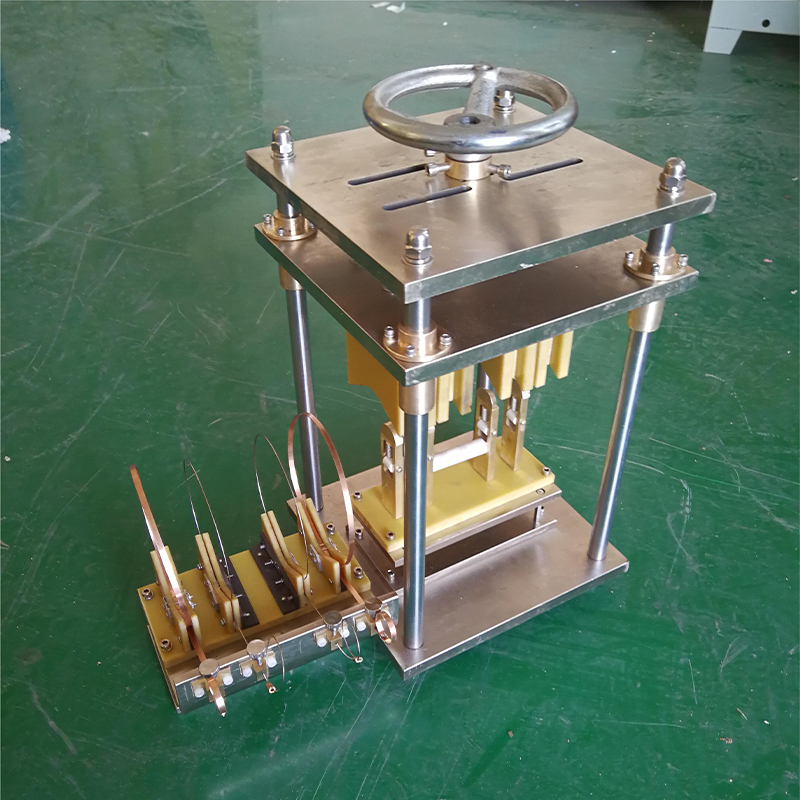

cable smoke density test machine company

The cable thermal elongation test is a crucial process in evaluating the performance and reliability of cables used in various industries. This test measures how much a cable lengthens when exposed to high temperatures, providing essential data for manufacturers and engineers to ensure product quality and longevity.

The authority of conducting such tests rests in adhering to stringent industry standards and guidelines. Recognized bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) set forth specific protocols to follow, ensuring that the tests yield reliable and comparable results across different manufacturers. Companies that follow these authoritative guidelines demonstrate their commitment to maintaining high-quality standards, thus gaining trust from their clients and industry peers. Establishing trustworthiness in cable manufacturing is paramount, as the integrity of electrical systems heavily depends on the cables used. Manufacturers and suppliers who prioritize testing and quality assurance measures are often preferred by industry professionals. By using cables that have undergone rigorous thermal elongation testing, companies can assure their clients of the reliability and durability of their products, fostering confidence and minimizing the risk of failure in critical applications. In conclusion, the cable thermal elongation test is an essential component of ensuring the reliability and safety of cables used across various sectors. The expertise involved in conducting these tests, adherence to authoritative industry standards, and the resulting trustworthiness of the products underscore their importance in the broader context of electrical and mechanical engineering. Whether for construction, data centers, or other industrial applications, thoroughly tested cables provide peace of mind and a foundation for successful operations across the globe.

The authority of conducting such tests rests in adhering to stringent industry standards and guidelines. Recognized bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) set forth specific protocols to follow, ensuring that the tests yield reliable and comparable results across different manufacturers. Companies that follow these authoritative guidelines demonstrate their commitment to maintaining high-quality standards, thus gaining trust from their clients and industry peers. Establishing trustworthiness in cable manufacturing is paramount, as the integrity of electrical systems heavily depends on the cables used. Manufacturers and suppliers who prioritize testing and quality assurance measures are often preferred by industry professionals. By using cables that have undergone rigorous thermal elongation testing, companies can assure their clients of the reliability and durability of their products, fostering confidence and minimizing the risk of failure in critical applications. In conclusion, the cable thermal elongation test is an essential component of ensuring the reliability and safety of cables used across various sectors. The expertise involved in conducting these tests, adherence to authoritative industry standards, and the resulting trustworthiness of the products underscore their importance in the broader context of electrical and mechanical engineering. Whether for construction, data centers, or other industrial applications, thoroughly tested cables provide peace of mind and a foundation for successful operations across the globe.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy