Suppliers of 15 Ton Tensile Testing Machines for Material Strength Analysis

Exploring the Market for 15% 20 Ton Tensile Testers Suppliers and Innovations

In the realm of materials testing, particularly for metals and plastics, tensile testers play a crucial role. One specific category of these machines is the 15% 20 ton tensile tester, a device that is engineered to measure the tensile strength of various materials, thereby ensuring they meet industry standards and specifications. This article explores the suppliers of this equipment, market trends, and the innovations that are shaping the future of tensile testing.

Understanding the 15% 20 Ton Tensile Tester

A 15% 20 ton tensile tester is designed to exert a maximum pulling force of 20 tons, making it suitable for a wide variety of materials—from metals to polymers. The reference to 15% usually implies a certain tolerance or capability in terms of measurement precision and operational efficiency. Such machines are indispensable in industries that require rigorous testing protocols to guarantee product safety and quality, including construction, automotive, aerospace, and manufacturing sectors.

The Importance of Reliable Suppliers

When it comes to sourcing a 15% 20 ton tensile tester, businesses must consider their suppliers carefully. Reliable suppliers should not only provide high-quality equipment but also offer excellent customer service, technical support, and training. Several well-known suppliers in the industry stand out

1. Instron A leading name in materials testing, Instron offers a range of tensile testers, including models that cater to specific force requirements. Their machines are known for their accuracy and user-friendly interfaces, making them popular in laboratories around the globe.

2. MTS Systems Corporation Renowned for its innovative testing solutions, MTS provides advanced tensile testing machines that come equipped with state-of-the-art software for data analysis. Their products are well-suited for both standard tests and specialized applications.

3. ZwickRoell This company specializes in quality assurance systems and provides robust tensile testers that can handle a variety of testing scenarios. Their machines are renowned for their durability and precision, suitable for both production and research environments.

15 ton tensile tester suppliers

4. Tinius Olsen A veteran in the testing equipment market, Tinius Olsen offers versatile tensile testing machines capable of accommodating different materials and testing needs. Their equipment is tailored for flexibility and efficiency.

Trends in Tensile Testing Equipment

The market for tensile testers is continuously evolving, influenced by technological advancements and changing needs in various industries. Some notable trends include

- Automation Automation is increasingly becoming a key feature in tensile testing equipment. Suppliers are incorporating automated systems that allow for remote operation, saving time and reducing human error during testing procedures.

- Data Analysis Software The integration of advanced data analysis software is revolutionizing how results are processed and evaluated. Modern tensile testers often come with software that allows for real-time data acquisition, enabling precise adjustments and immediate reporting of results.

- Sustainability Considerations As industries move towards more sustainable practices, suppliers are now focusing on creating energy-efficient and environmentally friendly testing machines. This shift is not only beneficial for the planet but also enhances the brand image of manufacturers.

- User-Centric Design Today's tensile testers are designed with the end-user in mind, featuring intuitive interfaces, robust safety measures, and comfortable setups that make operation smoother and more efficient.

Conclusion

The market for 15% 20 ton tensile testers is rich with opportunities, driven by technological advancements and the critical need for quality assurance in industrial processes. Reliable suppliers play a pivotal role in this sector, providing not just equipment but also the support necessary for effective material testing. As the industry continues to adopt more automated, data-rich, and sustainable practices, the future of tensile testing looks promising, paving the way for innovations that will enhance the reliability of materials used across various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

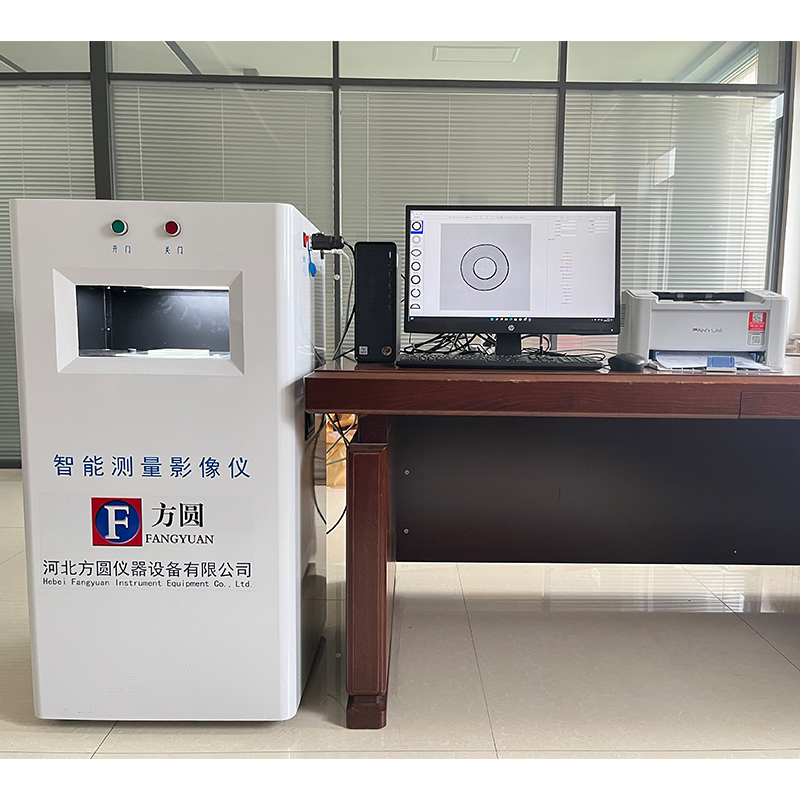

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy