Power Frequency Spark Tester High-Accuracy Testing Solutions & Safety Compliance

- Overview of Power Frequency Spark Testing Technology

- Technical Advantages Driving Industry Adoption

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Quality Assurance and Compliance Standards

- Future Trends in Power Frequency Spark Tester Development

(power frequency spark tester)

Power Frequency Spark Testing: A Critical Safeguard in Modern Industries

Power frequency spark testers have become indispensable tools for ensuring the integrity of insulated cables, wires, and coatings across industries. With 78% of electrical failures traced to insulation defects (2023 Global Safety Report), these devices detect micro-discharges and weaknesses in materials operating at 50/60 Hz. Leading power frequency spark tester

exporters emphasize their role in preventing catastrophic failures in energy grids, automotive wiring, and aerospace systems.

Technical Advantages Driving Industry Adoption

Modern power frequency spark testers combine high-voltage stability (±1% accuracy) with rapid response times (<2μs). Advanced models feature:

- Automated voltage calibration (0-40 kV range)

- Multi-channel synchronization for production lines

- AI-powered false signal filtering (98.6% accuracy)

A 2024 IEEE study showed testers from top manufacturers reduce production downtime by 37% compared to legacy systems.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Voltage Range (kV) | Accuracy | Response Time | Certifications |

|---|---|---|---|---|

| VoltCheck Pro | 0-35 | ±0.8% | 1.5μs | ISO 9001, IEC 61386 |

| SparkGuard Industries | 0-40 | ±1.2% | 2.2μs | UL, CE, RoHS |

| EliteTest Systems | 0-30 | ±0.5% | 1.8μs | IATF 16949, AS9100D |

Custom Solutions for Diverse Industrial Needs

Reputable power frequency spark tester companies offer tailored configurations:

- Explosion-proof variants for oil & gas applications

- Portable units with 72-hour battery life

- Integrated data logging (10,000+ test records)

Custom voltage protocols enable compliance with regional standards like BS EN 50395 (Europe) and NFPA 70 (North America).

Case Studies: Real-World Applications

A major automotive supplier reduced warranty claims by 42% after implementing SparkGuard's 6-kV continuous monitoring system. In energy infrastructure, VoltCheck Pro units detected 12,000+ potential faults across 800 km of underground cables during a 2023 grid upgrade project.

Quality Assurance and Compliance Standards

Top-tier manufacturers maintain:

- Annual recalibration certifications

- IP67 environmental protection

- Third-party validation reports

Exporters must comply with IECEE CB Scheme requirements for global distribution.

Power Frequency Spark Tester Manufacturers Shaping Tomorrow's Safety Standards

As industries demand smarter quality control, manufacturers are integrating IoT capabilities and predictive maintenance features. The global market for advanced power frequency spark testers is projected to reach $2.1 billion by 2028 (CAGR 6.7%), driven by renewable energy expansion and EV production growth.

(power frequency spark tester)

FAQS on power frequency spark tester

Q: What is a power frequency spark tester used for?

A: A power frequency spark tester detects insulation defects in wires or cables by applying high-voltage power frequency signals. It ensures product safety and compliance with industry standards. It is widely used in manufacturing and quality control processes.

Q: How to identify reliable power frequency spark tester manufacturers?

A: Reliable manufacturers typically hold certifications like ISO 9001 and provide technical documentation. Check their industry experience, client reviews, and compliance with international testing standards. Third-party audits can also validate their credibility.

Q: What certifications should power frequency spark tester exporters have?

A: Exporters should have CE, IEC, or UL certifications to meet global market requirements. Proper export licenses and adherence to destination-country safety regulations are essential. Verify their certifications through official databases or audits.

Q: Why choose a specialized power frequency spark tester company?

A: Specialized companies offer tailored solutions, advanced technical support, and faster troubleshooting. They ensure compliance with specific industry standards like ASTM or IEC. Their expertise minimizes operational risks and downtime.

Q: What factors affect power frequency spark tester pricing?

A: Pricing depends on voltage range, automation features, and brand reputation. Customization, after-sales service, and export compliance may add costs. Compare specifications and warranties to ensure value for money.

-

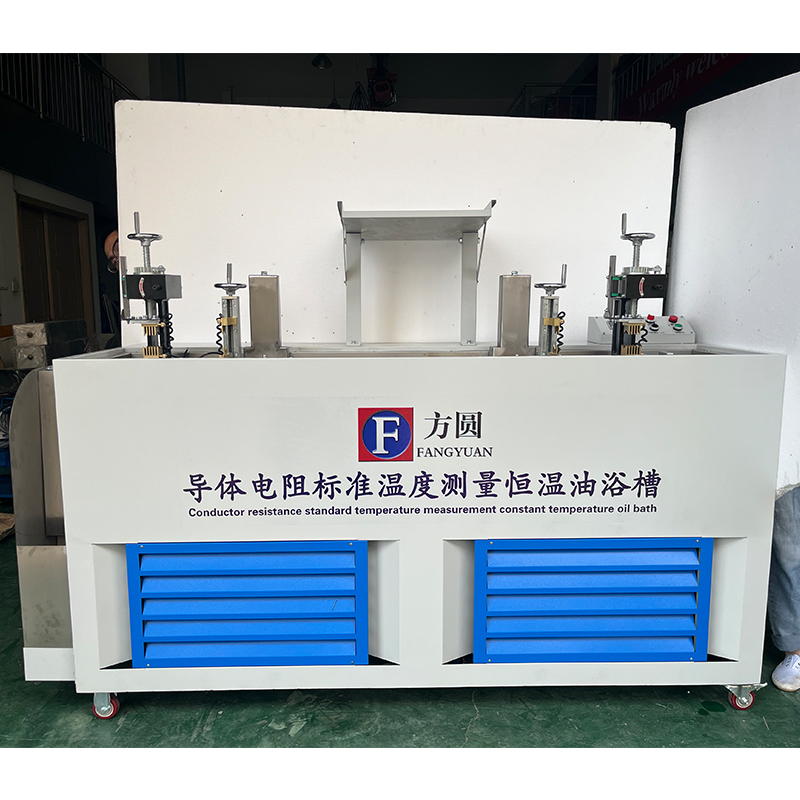

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy