Qer . 28, 2024 11:30

Back to list

Automatic Optical Measurement Machine Vendors A Guide to Top Suppliers

Automatic Optical Measurement Machines A Game Changer for Precision

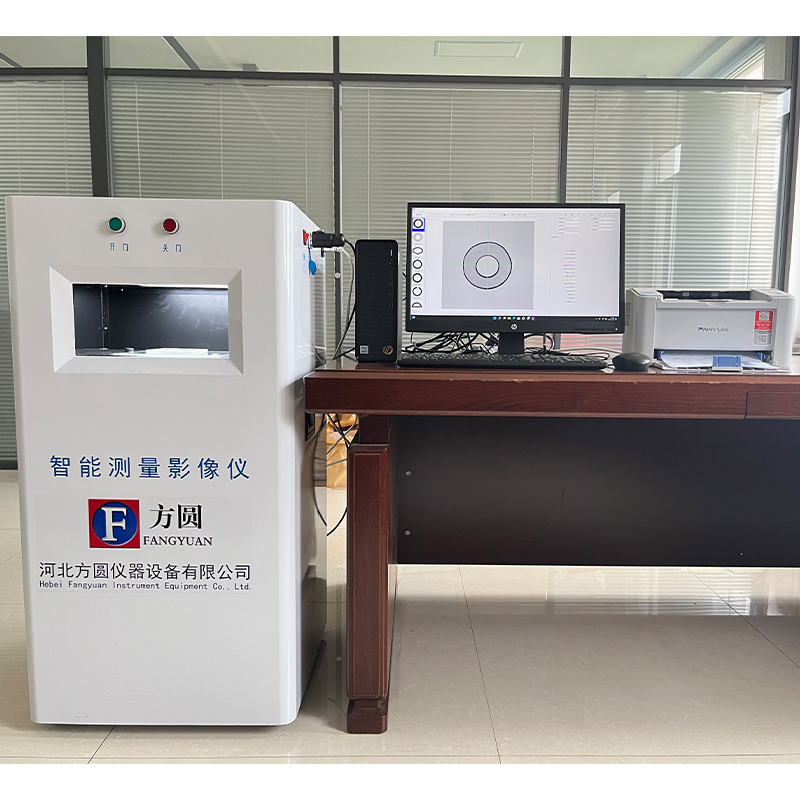

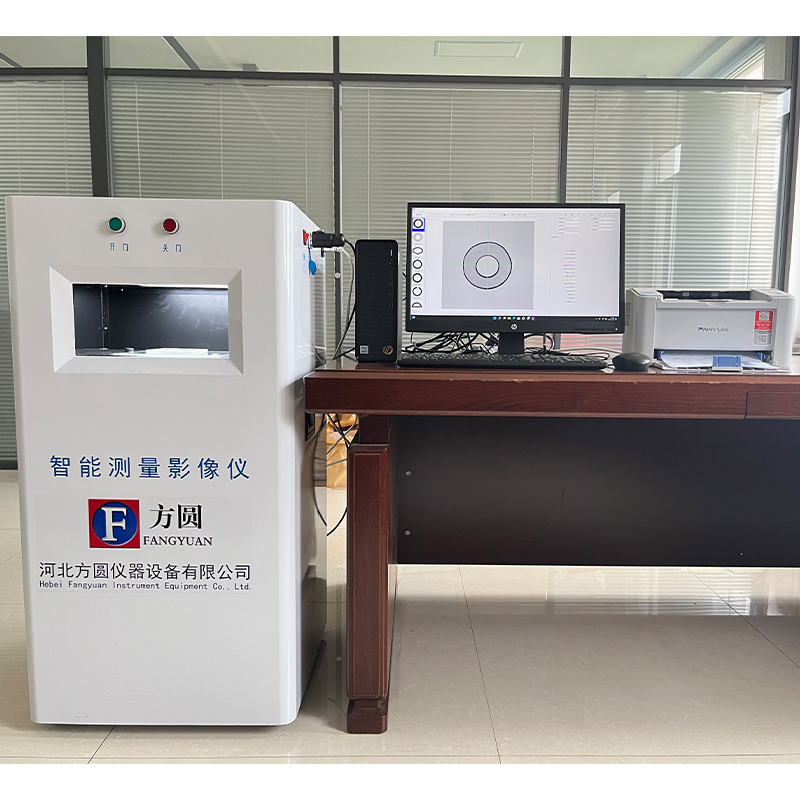

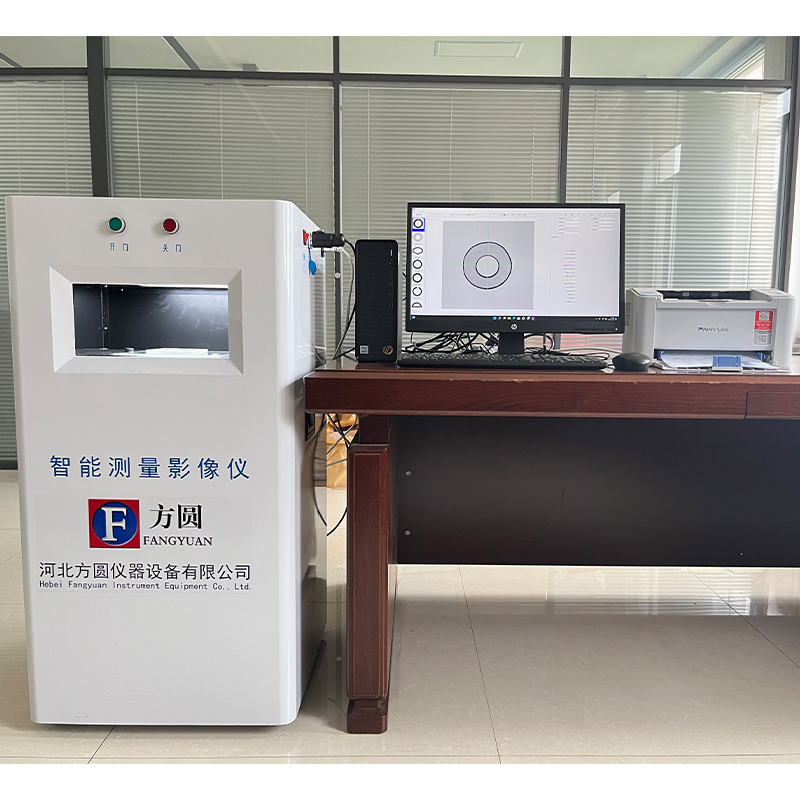

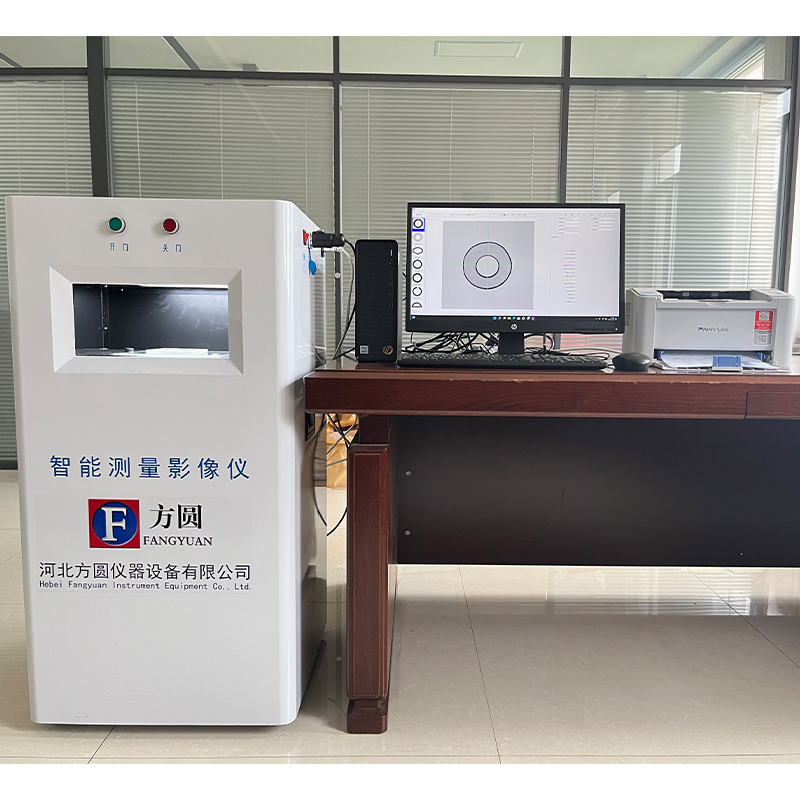

In the realm of precision engineering and quality control, automatic optical measurement machines have emerged as a revolutionary tool, transforming the way manufacturers ensure accuracy and consistency in their products. These sophisticated devices leverage advanced optics and digital image processing to perform complex measurements with unparalleled speed and accuracy, making them invaluable for suppliers who demand the highest standards in their offerings.

The operation of an automatic optical measurement machine is a testament to modern technological prowess. Equipped with high-resolution cameras and specialized lighting, these machines capture detailed images of components or assemblies. Through the use of sophisticated software algorithms, they can then analyze these images to measure dimensions, detect defects, and assess the overall quality of the item under inspection. This process is not only faster than manual measurements but also eliminates human error, ensuring that every part meets exacting specifications.

For suppliers, investing in such technology can be a strategic advantage. It allows them to provide consistent, high-quality products to their clients, enhancing their reputation for reliability and excellence. Moreover, the data gathered by automatic optical measurement machines can be used to refine manufacturing processes, leading to continuous improvement and innovation within the supply chain.

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration automatic optical measurement machine suppliers. Suppliers must evaluate factors such as the types of measurements required, the size and complexity of the parts, and the throughput needed for their operations. They must also consider the ease of integration with existing production lines and the level of technical support offered by the machine's manufacturer.

As we look to the future, it's clear that automatic optical measurement machines will continue to play a pivotal role in shaping the landscape of manufacturing and supply chain management. With their ability to provide rapid, accurate, and non-contact measurements, these machines are poised to become even more integral as industries strive for greater efficiency and quality control.

In conclusion, for suppliers seeking to maintain a competitive edge, embracing automatic optical measurement machines is not just a choice but a necessity. The precision and reliability they offer are essential for meeting the stringent demands of modern markets. As technology advances, these machines will undoubtedly become even more sophisticated, further solidifying their place at the heart of industrial quality assurance.

automatic optical measurement machine suppliers. Suppliers must evaluate factors such as the types of measurements required, the size and complexity of the parts, and the throughput needed for their operations. They must also consider the ease of integration with existing production lines and the level of technical support offered by the machine's manufacturer.

As we look to the future, it's clear that automatic optical measurement machines will continue to play a pivotal role in shaping the landscape of manufacturing and supply chain management. With their ability to provide rapid, accurate, and non-contact measurements, these machines are poised to become even more integral as industries strive for greater efficiency and quality control.

In conclusion, for suppliers seeking to maintain a competitive edge, embracing automatic optical measurement machines is not just a choice but a necessity. The precision and reliability they offer are essential for meeting the stringent demands of modern markets. As technology advances, these machines will undoubtedly become even more sophisticated, further solidifying their place at the heart of industrial quality assurance.

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration

However, selecting the right automatic optical measurement machine requires careful consideration automatic optical measurement machine suppliers. Suppliers must evaluate factors such as the types of measurements required, the size and complexity of the parts, and the throughput needed for their operations. They must also consider the ease of integration with existing production lines and the level of technical support offered by the machine's manufacturer.

As we look to the future, it's clear that automatic optical measurement machines will continue to play a pivotal role in shaping the landscape of manufacturing and supply chain management. With their ability to provide rapid, accurate, and non-contact measurements, these machines are poised to become even more integral as industries strive for greater efficiency and quality control.

In conclusion, for suppliers seeking to maintain a competitive edge, embracing automatic optical measurement machines is not just a choice but a necessity. The precision and reliability they offer are essential for meeting the stringent demands of modern markets. As technology advances, these machines will undoubtedly become even more sophisticated, further solidifying their place at the heart of industrial quality assurance.

automatic optical measurement machine suppliers. Suppliers must evaluate factors such as the types of measurements required, the size and complexity of the parts, and the throughput needed for their operations. They must also consider the ease of integration with existing production lines and the level of technical support offered by the machine's manufacturer.

As we look to the future, it's clear that automatic optical measurement machines will continue to play a pivotal role in shaping the landscape of manufacturing and supply chain management. With their ability to provide rapid, accurate, and non-contact measurements, these machines are poised to become even more integral as industries strive for greater efficiency and quality control.

In conclusion, for suppliers seeking to maintain a competitive edge, embracing automatic optical measurement machines is not just a choice but a necessity. The precision and reliability they offer are essential for meeting the stringent demands of modern markets. As technology advances, these machines will undoubtedly become even more sophisticated, further solidifying their place at the heart of industrial quality assurance. Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy