conductor resistance test factory

The Importance of Conductor Resistance Testing in Manufacturing

In the electrical engineering field, the reliability and efficiency of electrical systems hinge on the performance of conductors. The conductor resistance test factory plays a pivotal role in ensuring that these components meet strict quality standards before they are deployed in various applications. This article delves into the significance of conductor resistance testing, the methodologies employed, and its impact on overall electrical performance.

Understanding Conductor Resistance

Conductor resistance refers to the opposition that a conductor offers to the flow of electric current. This resistance is influenced by various factors, including the material of the conductor, its length, cross-sectional area, and temperature. In practical applications, low resistance is crucial for minimizing energy losses and preventing overheating, ultimately enhancing the efficiency of electrical systems.

The Conducting Testing Process

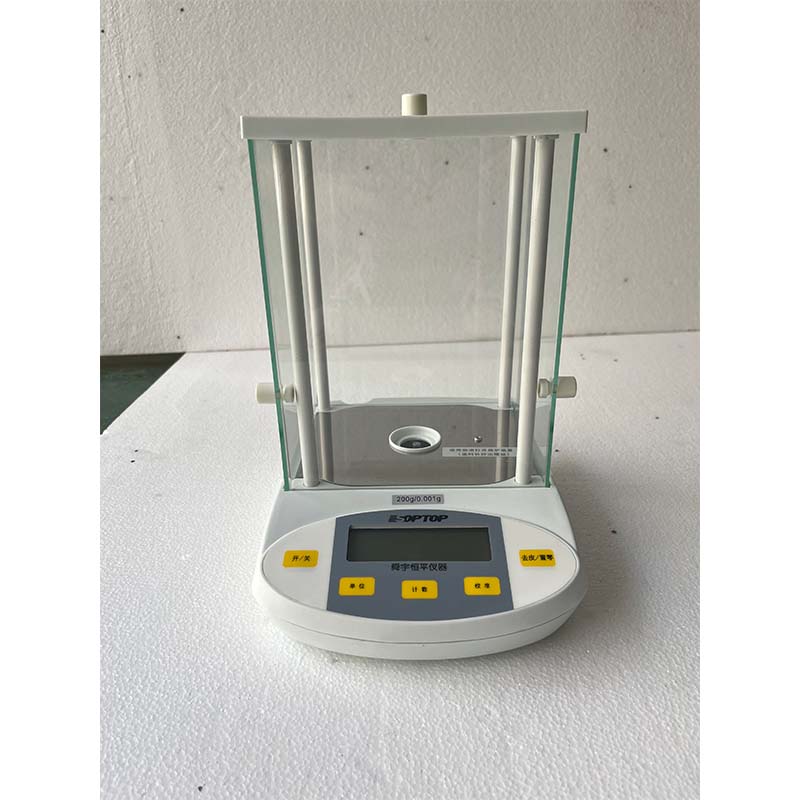

At a conductor resistance testing factory, a series of rigorous tests are conducted to evaluate the resistance of different conductor types, such as copper, aluminum, and alloys. The testing procedures typically involve the use of precise measurement instruments, such as ohmmeters and multimeters, to assess the resistance values accurately. These tests may be performed under controlled temperature conditions to ensure consistency and reliability in the results.

conductor resistance test factory

One common method used in testing is the four-wire measurement technique, which minimizes errors caused by lead and contact resistances. In this method, two wires are used to supply current while the other two measure the voltage drop across the conductor. This setup allows for highly accurate resistance measurements, essential for ensuring that the conductors adhere to industry standards.

Quality Assurance and Compliance

Conductor resistance testing is not just a technical requirement; it is also a critical aspect of quality assurance in manufacturing. By implementing rigorous testing protocols, factories can identify defects and inconsistencies in conductor materials before they enter the market. This proactive approach helps in mitigating potential failures and ensuring compliance with international standards, such as IEC and ASTM, which govern the performance of electrical components.

Conclusion

In conclusion, conductor resistance testing is an indispensable process in the manufacturing of electrical systems. It not only ensures the quality and reliability of conductors but also enhances the overall performance and safety of electrical installations. As industries continue to demand higher efficiency and reliability in their electrical systems, the role of conductor resistance test factories will only become more prominent, driving innovation and excellence in the field of electrical engineering. Ensuring low resistance in conductors ultimately supports the development of sustainable and efficient energy solutions for the future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy