Leading Manufacturers of Fiber Tensile Strength Testing Equipment for Accurate Results

Understanding Fiber Tensile Strength Testers and Their Manufacturers

In the realm of materials testing, one of the most critical parameters to evaluate is tensile strength, particularly for fibers used in various industrial applications. The process of determining tensile strength is performed using specialized equipment known as fiber tensile strength testers. This article will explore the importance of these testers, how they function, and what to consider when selecting a manufacturer.

What is Tensile Strength?

Tensile strength refers to the maximum amount of tensile (stretching) stress a material can withstand before failure. For fibers, this property is vital, as it dictates how the material behaves under tension. High tensile strength is often required in applications like textiles, ropes, and composite materials used in construction and aerospace industries.

The Role of Fiber Tensile Strength Testers

Fiber tensile strength testers are specifically designed to measure the tensile strength of a variety of fibrous materials, such as natural and synthetic fibers. These testers apply a controlled force to a fiber sample until it reaches its breaking point. The equipment typically measures the force applied and the elongation of the material, helping manufacturers and researchers understand how a fiber will perform in real-world applications.

In addition to measuring tensile strength, these machines often provide insights into other mechanical properties, such as elongation at break, modulus of elasticity, and energy absorption. This comprehensive analysis is crucial for quality assurance, material selection, and product development.

Key Features of Fiber Tensile Strength Testers

When purchasing a fiber tensile strength tester, consider the following features

1. Testing Capacity Ensure the tester can handle the specific types of fibers you intend to test. Different fibers have varying strengths, so the machine must accommodate a wide range of tensile capacities.

2. Precision and Accuracy Look for testers with advanced sensors and data acquisition systems that guarantee precise measurements. Digital displays and computer interfaces can enhance ease of use and result interpretation.

fiber tensile strength tester manufacturer

3. Speed and Efficiency High testing speed can significantly reduce time during quality control processes. Automated functions can streamline testing, making it easier for laboratories to maintain productivity.

4. Versatility Many modern testers are designed to accommodate multiple testing standards (e.g., ASTM, ISO). This versatility is essential for manufacturers who export products and need to comply with different international standards.

5. User-Friendly Interface An intuitive interface for the operator adds a layer of convenience, allowing for quicker familiarity with the machine. Features like touchscreen controls, easy data export options, and detailed manuals can enhance the user experience.

Choosing the Right Manufacturer

Selecting a reliable manufacturer is critical to ensuring the quality and longevity of your fiber tensile strength tester. Here are some tips on how to choose

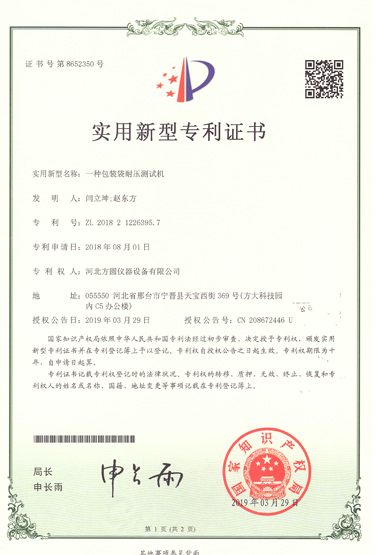

- Experience and Reputation Look for manufacturers with a solid industry reputation and years of experience in producing testing equipment. Reviews and testimonials can provide insight into the quality of their products and customer service.

- Technical Support and Service Opt for manufacturers that offer comprehensive technical support, including installation, calibration, and ongoing maintenance. This level of support is crucial, especially in the initial phases of using the equipment.

- Customization Options Some manufacturers offer customizable solutions tailored to specific testing needs. This flexibility can be invaluable, particularly for specialized applications.

- Price vs. Value While it might be tempting to go for the cheapest option, remember that quality and durability are essential. Evaluate the long-term value rather than just the upfront cost.

Conclusion

Fiber tensile strength testers play an indispensable role in ensuring the reliability and performance of fibrous materials across multiple industries. By understanding how these testers function and what to consider when selecting a manufacturer, businesses can make informed decisions that support their quality assurance goals. With advancements in technology, the future of material testing promises even greater accuracy and efficiency, solidifying the importance of these machines in material science.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy