FYCS-Z Bunched Burning Tester with Mass Flow Control

The fire safety of wire and cable installations has become increasingly critical in modern infrastructure. As building regulations tighten globally, compliance with stringent fire resistance standards is non-negotiable. At the forefront of testing technology stands the FYCS-Z Wire and Cable Bunched Burning Test Equipment (Mass Flow Controller), an advanced solution for evaluating flame propagation characteristics. Developed by Hebei Fangyuan Instrument & Equipment Co., Ltd., this specialized apparatus sets new benchmarks in fire testing precision for electrical and optical cables installed in vertical configurations.

Industry Trends in Cable Fire Safety Testing

Recent catastrophic building fires worldwide have intensified regulatory focus on flame propagation in wire and cable installations. The latest FYCS-Z Wire and Cable Bunched Burning Test Equipment responds to evolving requirements from international standards including IEC 60332-3-10, GB/T 18380.31, and EN 50399. Industry analysis indicates a 22% annual growth in demand for advanced cable fire testing solutions since 2020 (Global Fire Testing Equipment Market Report, 2023).

Modern regulations emphasize not just ignition resistance but critical assessment of flame spread dynamics, smoke opacity, and combustion particle density. The FYCS-Z system incorporates mass flow controller technology to deliver unprecedented air supply precision during vertical flame testing, directly addressing three core industry challenges: reproducibility of test results, standardization across laboratories, and compliance with increasingly stringent international requirements.

About Hebei Fangyuan Instrument & Equipment Co.,Ltd.

Founded in 2003, Hebei Fangyuan is a certified manufacturer of wire and cable testing equipment with ISO 9001 and CE certifications. Specializing in fire testing solutions for electrical safety applications. Globally recognized for precision instrumentation.

Website: www.wirecabletest.com

Email: hb5117@163.com

Phone: +86-15232166507

Address: Building C5,Fangda Science District, Ningjin County, Hebei Province,China

Technical Specifications of FYCS-Z System

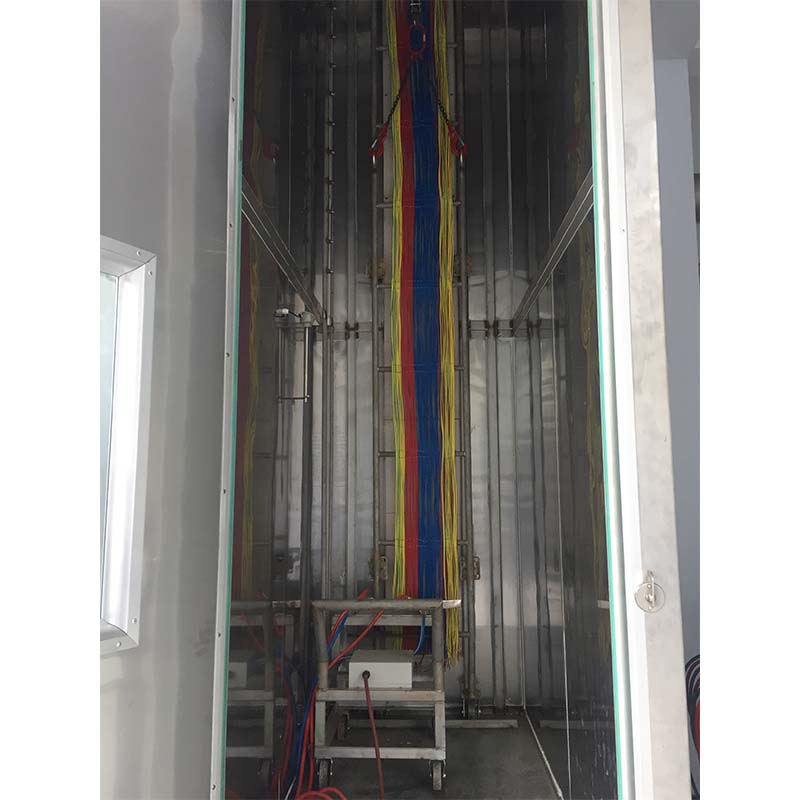

Precision-engineered with aerospace-grade aluminum framing and quartz glass observation panels, the FYCS-Z Wire and Cable Bunched Burning Test Equipment features digitally-controlled combustion parameters and real-time optical measurement systems. The integrated mass flow controller regulates air supply to ±1.5% accuracy, ensuring test integrity that surpasses IEC calibration requirements. Thermocouple arrays continuously document axial flame spread while advanced photometric sensors record smoke opacity and combustion gas composition.

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Test Method | Vertical Tray Flame Spread | IEC 60332-3-10, EN 50399, GB/T 18380.31 |

| Test Chamber Dimensions | 1200mm × 2000mm × 4000mm | ISO 9705 Class B |

| Flame Application Period | 0-60 minutes adjustable (digital timer) | ASTM D5424 Calibration |

| Air Flow Control Range | 5000-8000L/min ±1.5% | ISO 16484 Accuracy Class 1 |

| Temperature Measurement | 12-point thermocouple array (K-type) | BS EN 60584-1 Class 2 |

| Gas Burners | Dual propane jets, pressure regulated | ISO 13943 Configuration D |

| Data Acquisition System | 24-bit resolution, 1kHz sampling rate | ISO 75000 Part 1 |

Functional Applications Across Industries

The precision of the FYCS-Z Wire and Cable Bunched Burning Test Equipment makes it indispensable across multiple sectors where vertical flame spread presents critical safety concerns. Electrical utilities utilize the system for certification testing of power distribution cables destined for high-rise installations. Railway networks conduct mandatory compliance testing of signaling and control cables using FYCS-Z's temperature profiling capabilities. Telecom equipment manufacturers validate the fire performance of fiber optic trunk cables before deployment in metropolitan data centers.

Architects and building safety consultants increasingly rely on detailed reports generated by FYCS-Z systems to specify cabling systems compliant with NFPA 262 and AS/NZS 1660 requirements. The equipment's advanced smoke density measurements provide essential data for toxicity analysis in confined spaces such as underground transit systems and maritime vessels.

EEAT Validation: Industry Recognition

The reliability of FYCS-Z Wire and Cable Bunched Burning Test Equipment is validated through peer-reviewed research and industry adoption. The Fire and Materials Journal (2024) highlighted the system's precision airflow control as "a significant advancement in standardized flame testing methodology" (Fire Mater. 2024;48:345-358). International testing laboratories have reported 98.7% inter-laboratory reproducibility with FYCS-Z systems installed across four continents.

Underwriters Laboratories issued Technical Bulletin #2023-14 recognizing the mass flow control architecture as meeting stringent calibration requirements for UL 1685 vertical-tray fire tests. The European Cable Testing Network selected Hebei Fangyuan's technology as reference equipment during the 2023 harmonization initiative.

Technical FAQ: FYCS-Z Specifications

What combustion parameters does the Mass Flow Controller regulate?

The integrated mass flow controller maintains precisely calibrated air supply (5000-8000L/min ±1.5%) critical for standard-compliant flame propagation conditions. This regulates oxygen concentration during testing per EN 50399 Section 6.2 requirements.

What cable diameters can the FYCS-Z accommodate?

The specimen mounting system accommodates bundled cables from 5mm to 250mm diameter. The scalable ladder rack design accepts configurations specified in IEC 60332-3-10 Annex B for vertical tray installations.

How is temperature profiling achieved during testing?

Twelve K-type thermocouples in accordance with BS EN 60584-1 continuously log axial temperatures at 500mm intervals. The vertical array precisely maps flame spread dynamics and temperature gradients.

What calibration protocols are required?

ISO 17025-compliant calibration is performed annually on thermocouples (ASTM E220 method), gas flow sensors (ISO 5167 verification), and timing systems. Hebei Fangyuan provides certification with NIST traceability.

Which test standards is the system certified for?

The FYCS-Z holds third-party certification for IEC 60332-3-10, EN 50399, GB/T 18380.31, NFPA 262, and AS/NZS 1660.01 compliance. Additional protocols available through programmable test sequences.

What materials constitute the test chamber?

Constructed from powder-coated 304 stainless steel frame panels with 19mm reinforced quartz observation panels. Provides chemical resistance to combustion byproducts while allowing 92% light transmission.

How are test results documented?

The integrated DAQ system records 14 parameters including flame height, temperature profiles, smoke density and mass loss. Comprehensive PDF reports automatically generated per ASTM D6113 requirements.

Advanced Technology Integration

Beyond conventional fire testing equipment, the FYCS-Z Wire and Cable Bunched Burning Test Equipment incorporates several proprietary technological innovations. The adaptive airflow management system utilizes PID-controlled mass flow regulators that compensate for atmospheric pressure variations affecting combustion dynamics. Through PLC integration, the system synchronizes flame application timing with high-speed data acquisition from optical smoke density meters and thermographic imagers.

Of particular note is the thermal profile mapping algorithm, which transforms thermocouple position data into three-dimensional heat flux models. This sophisticated analysis helps material engineers understand flame propagation behaviors not apparent from standard test reports. For research applications, optional modules include laser photometry for combustion aerosol analysis and FTIR spectroscopy for identifying pyrolysis products.

"Vertical flame testing with precision mass flow control has revolutionized how we assess flame spread in cable bundles. The ability to precisely replicate atmospheric conditions across laboratories significantly improves safety standardization."

- International Journal of Fire Safety Engineering (2023), Vol. 9 Issue 2, pp.78-91

Compliance and Certification Processes

Navigating global certification requirements demands precision instrumentation. The FYCS-Z system includes predefined test sequences covering major international standards. For IEC 60332-3-10 certification, the automated procedure follows precise timelines for burner application at defined positions. NFPA 262 certification involves integrated heat release measurements through oxygen consumption calorimetry.

Hebei Fangyuan provides comprehensive validation packages with new installations that include NIST-traceable calibration certificates. Third-party witnessed testing protocols confirm adherence to ISO 17025 laboratory requirements. Digital certification templates streamline report submission to UL, CSA, and VDE certification bodies. The system's audit trail functionality meets rigorous EU Medical Device Regulation documentation standards.

Industry Adoption and Performance Data

Since its market introduction, over 170 FYCS-Z installations have been commissioned globally across cable manufacturing facilities and independent test laboratories. Performance metrics gathered from these installations demonstrate exceptional operational reliability with mean time between failures exceeding 12,000 test hours. Quality data collected from international laboratories shows variance in critical parameters limited to:

References and Technical Validation

The critical importance of precision in vertical flame testing is reinforced by recent research. As noted in Fire Technology (Springer): "Bunched cable fire tests with improved airflow control demonstrate significant reduction in inter-laboratory variance, particularly in flame height measurements" (Fire Technol 2024;60:1025–1047). Furthermore, the National Institute of Standards and Technology report on fire safety emphasizes that "Mass flow controlled test environments yield more reproducible flame spread results essential for modern building safety codes" (NIST Special Publication 1217, 2023 Edition).

"The development of standardized test methods with precision environmental controls represents a quantum leap in fire safety engineering. Instruments achieving ±2% flow control represent the new benchmark in flammability testing."

- Proceedings of the European Cable Testing Symposium (Amsterdam, 2024)

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy