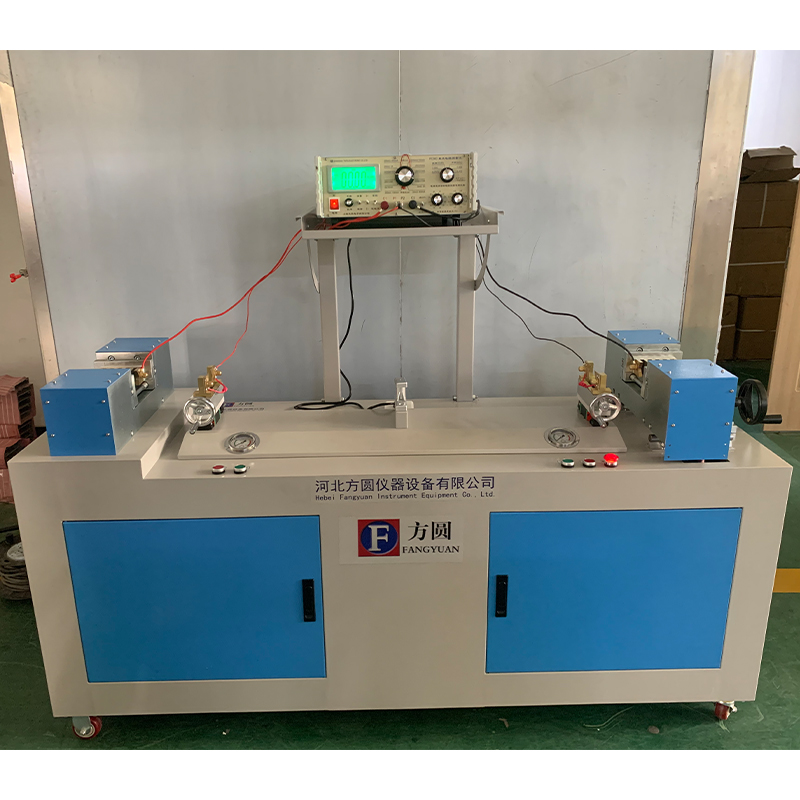

Resistance Testing Equipment Suppliers and Their Key Features for Quality Assurance

Understanding Resistance Test Manufacturers

Resistance testing is a critical process in various industries, including electrical, automotive, and manufacturing. It ensures that materials and components can withstand certain levels of resistance before being deployed in real-world applications. This testing measures resistance to flow, mechanical stress, and other factors that could affect performance and safety. To achieve reliable and accurate results, industries turn to specialized manufacturers that produce resistance testing equipment. This article explores the significance of resistance test manufacturers, the technology they employ, and the role they play in quality assurance.

The Importance of Resistance Testing

In many sectors, resistance testing serves as a vital gatekeeping function. For example, in the electrical industry, it helps ensure that conductors can handle the expected load without overheating or failing. In the automotive sector, resistance testing ensures that materials can withstand harsh conditions, such as extreme temperatures and mechanical stress. Manufacturers rely on these tests to comply with industry standards and regulations, ensuring safety and functionality.

Moreover, effective resistance testing can lead to cost savings. By identifying potential failures before products reach the market, companies can avoid costly recalls or replacements. Therefore, the role of resistance test manufacturers is essential in maintaining not only industry standards but also the integrity of products.

Role of Resistance Test Manufacturers

Resistance test manufacturers specialize in creating various types of testing equipment, including digital multimeters, insulation resistance testers, and specialized devices for measuring resistivity. These manufacturers continually innovate, developing more sophisticated tools that offer greater precision and ease of use.

The technological advancements in the field have made it possible for manufacturers to produce testing equipment that is compact, portable, and user-friendly. Instruments such as advanced handheld testers can provide real-time data and analytics, making it easier for technicians to assess the health and resistance of various materials on-site.

Key Features of Resistance Testing Equipment

resistance test manufacturers

Resistance testing equipment typically comes with several features that enhance its efficacy. Some of the key characteristics include

1. Accuracy and Precision Modern resistance testers are designed to provide highly accurate readings, which are crucial for compliance and safety. 2. User-Friendly Interfaces Many contemporary devices feature digital displays and intuitive controls, allowing users to navigate functions easily.

3. Data Logging and Analysis Some advanced models offer built-in data logging capabilities, enabling users to collect and analyze test results over time.

4. Versatility Quality resistance testing equipment can often be used in various applications, making it a flexible choice for manufacturers who operate in multiple sectors.

Challenges Faced by Resistance Test Manufacturers

While the demand for resistance testing equipment is significant, manufacturers face challenges that impact their operations. Rapid technological advancements mean that companies must invest in research and development to keep their products competitive. Additionally, the increasing focus on sustainability and eco-friendly practices is pushing manufacturers to develop energy-efficient devices.

Furthermore, the global supply chain disruptions caused by events such as the COVID-19 pandemic have led to delays in sourcing materials and components needed for production. Manufacturers must navigate these challenges while continuing to meet the demands of their customers.

Conclusion

Resistance test manufacturers are vital to ensuring the safety, reliability, and performance of products across various industries. By providing advanced testing equipment and solutions, these manufacturers play a crucial role in quality assurance and compliance. As technology evolves, the resistance testing industry will undoubtedly continue to grow and adapt, meeting the challenges of a changing world while ensuring the integrity of products used in critical applications. Investing in reliable resistance testing equipment is not just a regulatory requirement but also a strategic decision that can lead to long-term success and safety.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy