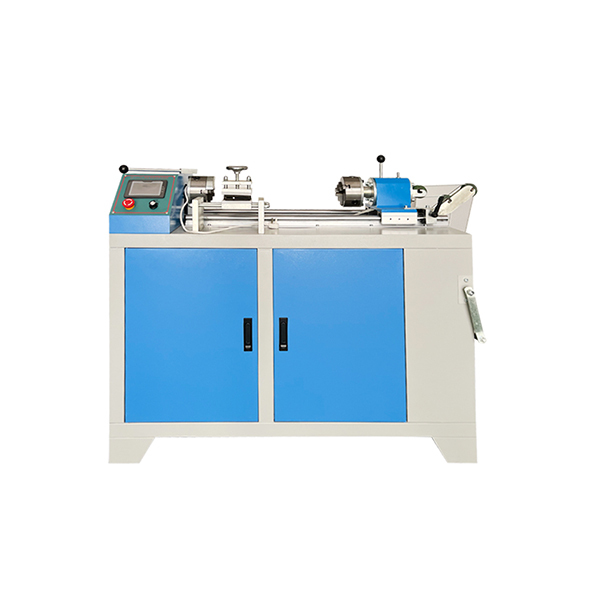

Suppliers of High-Quality Cable Bend Test Machines for Rigorous Performance Evaluation and Reliability Testing

Understanding the Importance of Cable Bend Test Machines and Their Suppliers

In an era where technology intertwines with daily life, the reliability and performance of electrical cables are paramount. One critical test in ensuring that cables maintain integrity and functionality under various conditions is the cable bend test. As industries continually seek to improve product quality and durability, cable bend test machines have emerged as essential testing equipment. This article delves into the importance of these machines and how to select a reputable supplier.

What is a Cable Bend Test Machine?

A cable bend test machine is designed to assess a cable's ability to withstand bending stresses over time without suffering damage or failure. The test typically involves bending a cable to a specific angle and radius for a predetermined number of cycles while monitoring its response. The outcomes are crucial for establishing compliance with international standards and ensuring the cable's longevity and performance in real-world applications.

Importance of Cable Bend Testing

1. Durability Assurance Cables are often subjected to bending in their intended environments, such as electrical installations, industrial applications, and consumer electronics. Testing the cables' endurance against bending ensures that they can perform their functions without degrading over time.

2. Compliance with Standards Many regulatory standards, such as IEC and UL, require thorough testing of electrical components. Utilizing a cable bend test machine aids manufacturers in meeting these compliance requirements, thus enhancing their credibility and marketability.

3. Preventing Failures By simulating real-life bending scenarios, manufacturers can identify potential points of failure early in the development process. This proactive approach minimizes the risk of costly recalls and repairs after the cables are in use, safeguarding both the company’s reputation and customer safety.

4. Quality Improvement Regular use of cable bend testing helps manufacturers refine their production processes, leading to improvements in product quality. Insights gained from testing can inform material selection and design choices, ultimately resulting in superior end products.

cable bend test machine supplier

Choosing a Reliable Supplier

When it comes to acquiring a cable bend test machine, selecting a reliable supplier is crucial to ensuring long-term success. Here are key considerations during the selection process

1. Reputation Research potential suppliers thoroughly. Look for reviews and testimonials from other companies in your industry. Suppliers with a proven track record are more likely to provide quality machines and customer service.

2. Technical Expertise A supplier should not only offer machines but also demonstrate comprehensive knowledge of testing protocols and standards. Their experts should provide valuable advice on selecting the right equipment tailored to your specific testing needs.

3. After-Sales Support Consider the level of support the supplier offers post-purchase. This includes machine installation, training for personnel, and timely replacement parts. Strong after-sales support can significantly enhance operational efficiency.

4. Custom Solutions Different organizations may have unique requirements for cable testing. A good supplier should be willing to offer customized solutions and modifications to their standard machines to cater to specific client needs.

5. Innovation and Technology The technology used in testing machines is continually evolving. Opt for suppliers who stay abreast of the latest innovations and offer advanced features such as digital monitoring, automated reporting, and integration with other testing systems.

Conclusion

In conclusion, cable bend test machines play a vital role in guaranteeing the reliability and safety of electrical cables. As industries invest in technology and quality assurance, partnering with a reputable supplier becomes essential. By focusing on reputation, expertise, support, customization, and innovation, businesses can ensure that they select the right supplier to meet their testing needs effectively. With the appropriate machine in hand, manufacturers can confidently produce cables that meet the rigorous demands of the modern world, ultimately contributing to enhanced safety and performance.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy