Winding and Torsion Testing Equipment Manufacturer for Quality Assurance Solutions

Understanding Winding and Torsion Testing Machines

In the world of material science and engineering, the integrity of materials is paramount. Among the key equipment employed to assess these properties are winding and torsion testing machines. These machines are essential for evaluating materials' mechanical characteristics, such as tensile strength, elastic modulus, and torsional stress, in various applications including automotive, aerospace, and construction industries.

The Importance of Winding and Torsion Testing

Before diving into the specifics of these machines, it is crucial to comprehend why winding and torsion testing is significant. Materials used in critical applications must endure various forms of stress and strain while maintaining their performance and safety standards. Winding tests help ascertain how materials react when subjected to twisting or bending forces, providing valuable data on their elasticity and durability. Similarly, torsion testing evaluates how materials withstand rotational forces, offering insights into their structural integrity under different loading conditions.

Both tests are necessary for developing new materials and improving existing ones, particularly composites that are increasingly used in advanced engineering applications. With the rise in demand for lightweight yet strong materials, the ability to accurately measure and predict material behavior under various stresses has never been more critical.

Features of Winding and Torsion Testing Machines

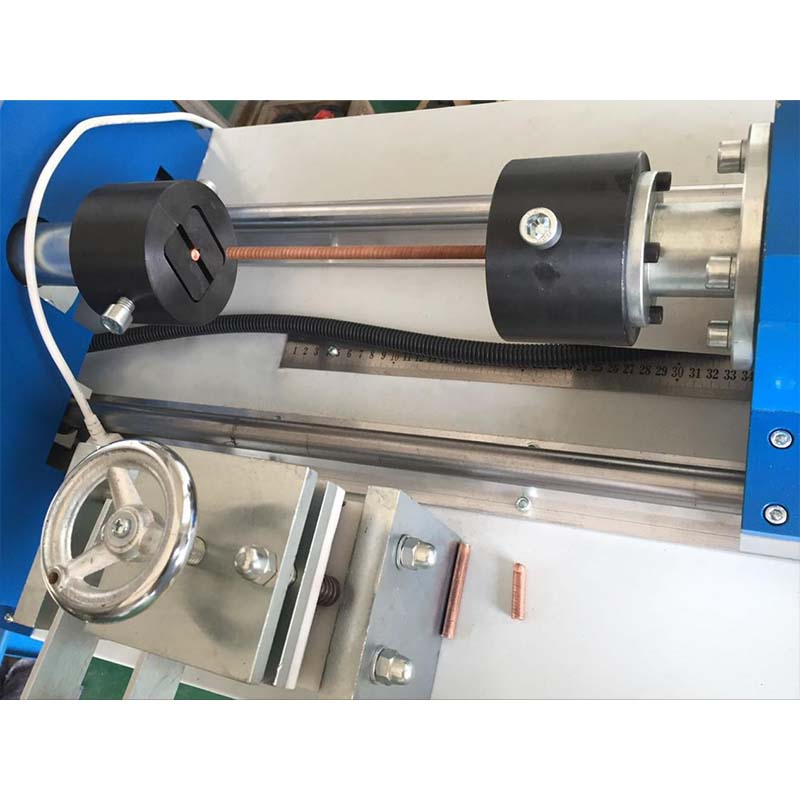

Modern winding and torsion testing machines are equipped with advanced features to ensure precise and reliable testing outcomes. These machines typically include digital control systems that allow for the real-time monitoring of stress and strain during tests. Furthermore, they often come with user-friendly software that enables engineers to analyze data quickly and efficiently. Such software can generate detailed reports, graphs, and statistical analyses, streamlining the process of data evaluation.

The machines are designed to accommodate various test specimens and configurations, ensuring versatility in testing different types of materials, from metals to complex polymers. Some advanced models even allow for simultaneous testing, enhancing productivity without compromising on accuracy. This adaptability makes them invaluable in laboratories and research institutions where different testing methods may be employed based on specific research objectives.

winding and torsion testing machine company

Applications Across Industries

Winding and torsion testing machines have a wide range of applications across numerous industries. In the aerospace sector, for example, materials must withstand extreme conditions, and the integrity of components can be life-critical. Thus, precise testing helps ensure that materials meet stringent safety regulations. Similarly, in the automotive industry, manufacturers depend on these tests to validate materials for performance under stress and to enhance vehicle safety and efficiency.

In construction, winding and torsion tests are vital for assessing the structural capabilities of building materials. These tests assist engineers in choosing the right materials for high-rise buildings, bridges, and other infrastructures that must endure significant loads and pressures over time.

Future Trends in Testing Technology

As technology advances, so too do the capabilities of winding and torsion testing machines. With the integration of artificial intelligence and machine learning algorithms, future testing machines are likely to offer even more accurate predictions of material behavior. This evolution will enable quicker development cycles for new materials and products, promoting innovation across multiple sectors.

Additionally, as environmental concerns become more pressing, there is a growing emphasis on sustainable materials. Testing machines will play a crucial role in validating the performance of these eco-friendly alternatives, ensuring they meet industry standards for both safety and effectiveness.

Conclusion

In summary, winding and torsion testing machines are indispensable tools in material testing, offering vital insights that help engineers and researchers ensure the safety and reliability of materials across a wide array of industries. As technology continues to evolve, the role of these machines will only become more significant, paving the way for advancements in material science and engineering. Their versatility and precision make them essential for the rigorous demands of modern engineering applications, contributing to safer, more innovative products for the future.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy