cable flexibility test machine suppliers

Understanding Cable Flexibility Test Machines and Their Suppliers

In the ever-evolving field of electrical and electronic engineering, the demand for high-quality cables has skyrocketed. With applications ranging from telecommunications to automotive industries, cables must not only transmit signals or power effectively but also withstand various environmental stresses. This is where flexibility and durability tests become crucial. Cable flexibility test machines play an essential role in evaluating the performance of cables under different bending conditions, ensuring they meet industry standards. Understanding the suppliers of these machines can significantly impact the quality of cable testing processes.

The Importance of Cable Flexibility Testing

Cable flexibility testing involves assessing how well a cable can bend and twist without sustaining damage. This process is vital because many applications require cables to be routed in tight spaces where flexibility is crucial. A cable that is too rigid may break when subjected to specific movements or temperatures, leading to operational failures and safety hazards.

The flexibility test generally involves subjecting the cable to repeated bending and flexing cycles while monitoring for any signs of wear, cracking, or insulation failure. Establishing a standardized method of testing can help manufacturers produce cables that not only fit their application requirements but also ensure reliability over time.

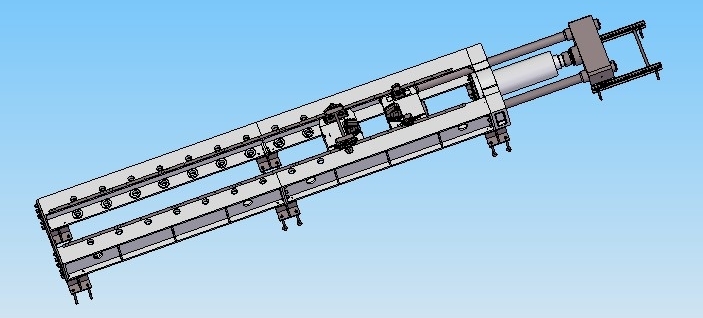

Key Features of Cable Flexibility Test Machines

Cable flexibility test machines come equipped with various features that make them suitable for rigorous testing. Some of these include

1. Adjustable Mandrels To accommodate different cable sizes and types, machines often come with interchangeable mandrels of various diameters.

2. Automated Testing Cycles Advanced machines can automate the bending cycles, allowing for consistent testing while reducing the likelihood of human error.

3. Data Acquisition and Analysis Many modern machines are equipped with software that can track performance metrics and provide detailed reports on cable flexibility and durability. This capability allows manufacturers to make informed decisions regarding cable designs.

4. Safety Features Safety is paramount in testing environments. Machines are often designed with features to prevent injuries during operation, such as emergency stop buttons and guards.

cable flexibility test machine suppliers

5. Compact Design Space is often a premium in manufacturing facilities, making compact machines an attractive option for manufacturers looking to maximize floor space.

Leading Suppliers of Cable Flexibility Test Machines

A number of reputable suppliers specialize in manufacturing cable flexibility test machines. Here are some of the prominent players in the market

1. Qualitest Known for its high-standard testing equipment, Qualitest provides a versatile range of cable testing machines, including flexibility testers. Their equipment often integrates advanced technology to ensure accurate results.

2. Instron A leader in material testing machinery, Instron offers cable flexibility test machines that combine precision with durability. Their machines are often used in research institutions as well as in commercial settings.

3. ZwickRoell This company specializes in testing systems and provides tailored solutions for cable testing. ZwickRoell machines are recognized for their reliability and innovative features.

4. Universal Testing Machines They offer a variety of testing machines, including cable flexibility test setups, providing customizable options to fit specific testing needs.

5. SANS With a focus on providing comprehensive cable testing solutions, SANS has built a reputation for quality and service in the electrical testing market.

Conclusion

The importance of cable flexibility testing in ensuring the quality and safety of electrical cables cannot be overstated. As industries continue to evolve, and with the growing complexity of cable applications, having access to reliable and efficient flexibility test machines is crucial. Selecting the right supplier can make a significant difference in the testing process, impacting not only the performance of the cables but also the overall success of manufacturing operations.

Investing in advanced cable flexibility test machines from reputable suppliers helps manufacturers comply with industry standards, improves product reliability, and drives innovation in cable design. As the market grows, it will be exciting to see how suppliers respond to new challenges and present solutions that enhance cable testing methodologies.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy