china cable bending test machine

Understanding the China Cable Bending Test Machine A Critical Tool for Quality Assurance

In today's fast-paced technological environment, the integrity and reliability of cables are paramount. The China Cable Bending Test Machine has emerged as an essential piece of equipment that plays a crucial role in ensuring the quality and durability of various types of cables. This article delves into the significance of cable bending tests, the features of these test machines, and their applications in the industry.

The Importance of Cable Bending Tests

Cables, whether they are used in telecommunications, electronics, or industrial applications, are subjected to a range of stresses during their operational life. One of the most significant stressors is bending, which can occur during installation, routine use, or as a result of environmental factors. Continuous bending can lead to wear and tear, resulting in cable failure, which can have devastating consequences, including system outages or safety hazards.

To mitigate these risks, manufacturers must conduct rigorous tests to assess how well their cables can withstand bending. The bending test simulates real-world conditions, allowing manufacturers to evaluate the performance of their products under stress. Such testing is crucial for ensuring compliance with industry standards and for maintaining customer trust.

Features of the China Cable Bending Test Machine

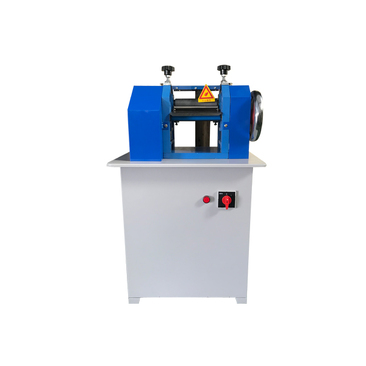

The China Cable Bending Test Machine is designed specifically to evaluate the bending performance of cables. Here are some of its notable features

1. Adjustable Test Angles Many machines offer the ability to adjust the bending angle, which allows for varied testing scenarios. This adaptability is crucial for cables designed for different applications requiring specific bending tolerances.

2. Automatic Control Systems Modern bending test machines often come with advanced computerized systems that can automatically control the bending cycle. This ensures consistency in testing, as machine operators can set parameters such as speed and duration.

china cable bending test machine

3. Data Acquisition and Analysis These machines are equipped with systems that record performance data during testing. By analyzing this data, manufacturers can identify potential weaknesses in their cables, make necessary design adjustments, and improve overall quality.

4. Robust Construction Given the mechanical stresses involved, these test machines are built to withstand tough operating conditions. High-quality materials are used to ensure longevity and reliability in testing.

5. User-Friendly Interface Many machines feature intuitive interfaces, making it easier for operators to configure settings and interpret results. This is essential in busy manufacturing environments where efficiency is key.

Applications in the Industry

The applications of the China Cable Bending Test Machine are extensive. Industries such as telecommunications, automotive, consumer electronics, and aerospace rely heavily on these machines to ensure the reliability of their products.

In telecommunications, for instance, cables must endure frequent bending during installation and ongoing use; therefore, manufacturers utilize bending test machines to guarantee their products meet rigorous standards. The automotive industry, with its emphasis on safety and reliability, also uses these machines to test wiring harnesses and other critical components.

Furthermore, manufacturers can ensure regulatory compliance by using cable bending test machines, which aligns with industry standards such as IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories) guidelines.

Conclusion

In conclusion, the China Cable Bending Test Machine is an indispensable tool for manufacturers aiming to ensure the quality, reliability, and safety of their cables. With its advanced features, ability to simulate real-world conditions, and applications across various industries, this testing equipment not only enhances product performance but also supports manufacturers in maintaining their reputations in an increasingly competitive market. By investing in quality assurance through rigorous testing, companies can mitigate risks, foster trust with consumers, and ultimately contribute to advancements in technology that rely on robust and durable cable systems.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy