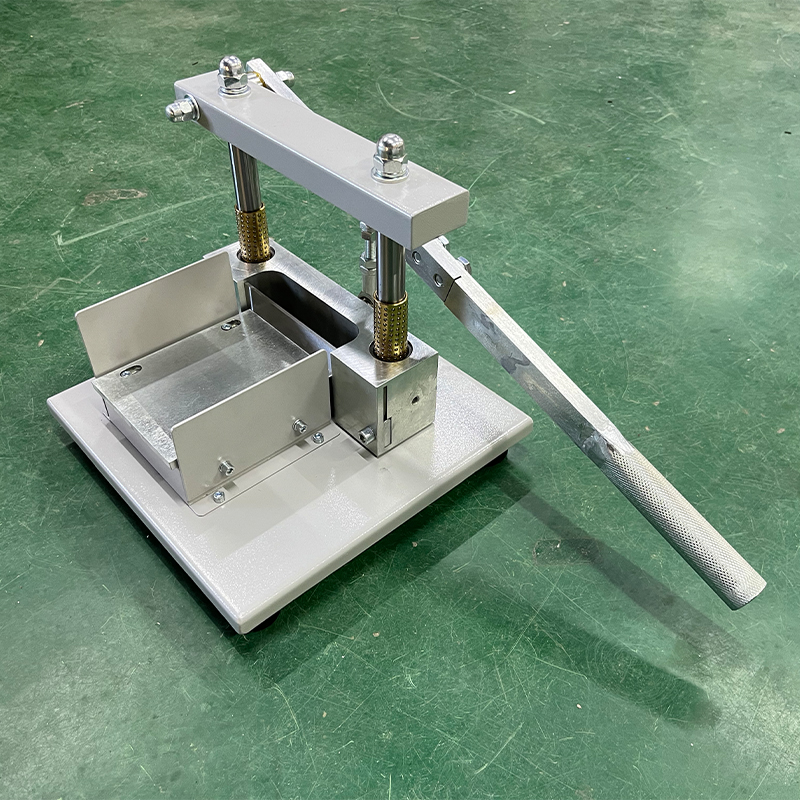

computer control tensile strength testing equipment

Computer-Controlled Tensile Strength Testing Equipment Revolutionizing Material Testing

The field of material testing has undergone significant transformation over the past few decades, particularly with the integration of computer technology into tensile strength testing equipment. With the demand for higher precision, efficiency, and reliability in material testing, computer-controlled systems have become essential tools in laboratories and industrial settings. This article explores the advantages, components, and applications of computer-controlled tensile strength testing equipment, shedding light on its critical role in modern material science.

Understanding Tensile Strength Testing

Tensile strength testing is a fundamental procedure used to determine how a material responds to tension—essentially, how much force is required to stretch or break the material. It provides vital information regarding a material’s mechanical properties, such as yield strength, ultimate tensile strength, and elongation. Traditionally, tensile testing was conducted using hydraulic or mechanical machines operated manually, which often involved significant variability and human error. With technological advancements, computer-controlled systems have emerged to provide consistency, accuracy, and enhanced functionality.

Advantages of Computer-Controlled Equipment

1. Precision and Accuracy One of the most significant benefits of computer-controlled tensile strength testing equipment is the high degree of accuracy it offers. Automated systems eliminate variability associated with manual operations, ensuring that each test is performed under the same conditions. This precision is essential for producing reliable and reproducible results, which are critical in quality assurance and research applications.

2. Data Management Computer-controlled systems often come equipped with sophisticated software that facilitates real-time data collection and analysis. This software not only captures the raw data from the tests but also processes it to generate meaningful insights through graphical representations and reports. Users can easily track trends, compare results, and compile comprehensive datasets for further analysis.

3. User-Friendly Interfaces Modern tensile testing devices are designed with user-friendly interfaces, making it easier for operators to set up and execute tests. Intuitive software guides users through the process, allowing even those with minimal experience to perform complex tests effectively. This accessibility enhances productivity and reduces the likelihood of human error.

4. Versatility Computer-controlled tensile strength testing equipment is incredibly versatile, capable of testing a wide range of materials, including metals, polymers, and composites. Various accessories and setups can be integrated into the system to accommodate different testing standards and specimen geometries. This adaptability is crucial in industries such as aerospace, automotive, and construction, where diverse materials are used.

5. Real-Time Monitoring Advanced testing systems allow for real-time monitoring of the materials being tested. This feature enables technicians to observe the behavior of materials under stress as the test is in progress, leading to immediate insights and the ability to make adjustments if necessary.

computer control tensile strength testing equipment

Key Components of a Computer-Controlled Tensile Strength Tester

1. Load Frame The load frame is the core component of any tensile tester, designed to apply controlled tensile forces to the specimen. In computer-controlled systems, load frames are typically servo-controlled, allowing for precise force application.

2. Grips and Fixtures These components hold the test specimen in place during testing. Advanced grips may include hydraulic or pneumatic mechanisms for easy specimen handling, while ensuring that there is minimal slippage or deformation.

3. Sensors and Transducers Load cells and extensometers are critical for measuring force and elongation, respectively. These sensors provide real-time data that the computer system analyzes to produce accurate measurements of the material's properties.

4. Control Software The accompanying software is integral for setting test parameters, monitoring real-time data, and generating reports. It can also store historical data for comparative analysis and quality control.

Applications in Industry and Research

Computer-controlled tensile strength testing equipment is indispensable across a multitude of industries. In aerospace and automotive sectors, it is used to ensure materials meet stringent safety standards. In construction, it helps verify the integrity of building materials, ensuring structures can withstand applied loads. Research and development labs utilize this equipment to innovate new materials, contributing to advancements in technology and manufacturing processes.

Conclusion

The advent of computer-controlled tensile strength testing equipment marks a significant leap forward in material testing methodologies. The enhanced precision, data management capabilities, and user-friendly interfaces not only improve the reliability of the results but also streamline the testing process across various industries. As material science continues to evolve, embracing technology in tensile testing will undoubtedly play a vital role in shaping the future of engineering and manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy