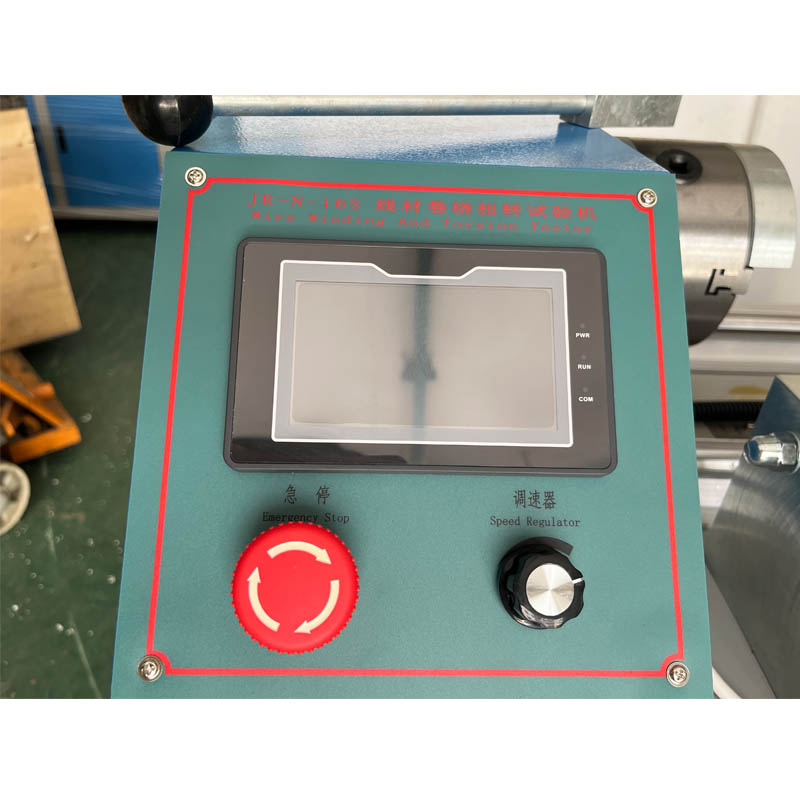

Factory Production of Wire Reverse Bending Test Machines for Precision Material Testing Applications

Wire Reverse Bending Test Machine A Key to Quality Assurance in Manufacturing

In the realm of quality assurance and material testing, the wire reverse bending test machine plays an essential role, particularly in industries that rely on wire products. These machines are designed to evaluate the mechanical properties of wire and ensure that they meet the necessary standards for durability and flexibility. As a critical tool for manufacturers and quality control engineers, understanding the functionality and importance of wire reverse bending test machines is vital.

What is a Wire Reverse Bending Test Machine?

A wire reverse bending test machine is a specialized device used to assess the performance of wire under bending stress. During the testing process, a wire specimen is subjected to repeated bending cycles, mimicking real-world applications where the wire may undergo flexing and bending throughout its lifecycle. The functionality of the machine allows for the measurement of parameters such as the number of bending cycles the wire can withstand before failure, the angle of bend, and the load applied during testing.

Importance in Quality Control

In industrial settings, quality control is paramount. Wire products must adhere to strict standards to ensure safety, performance, and longevity. The reverse bending test is crucial for identifying any potential weaknesses in the wire, including brittleness, poor tensile strength, and susceptibility to breakage. By conducting these tests, manufacturers can ascertain the reliability of their wire products, thereby minimizing the risk of product failure in the field.

Key Features of Reverse Bending Test Machines

wire reverse bending test machine factory

Modern wire reverse bending test machines are equipped with advanced features that enhance testing accuracy and efficiency. These machines often come with digital control systems and software that allow for precise adjustments to bending angles and load conditions. Additionally, many models include data acquisition systems that provide real-time monitoring and analysis of test results. This advanced technology enables manufacturers to capture detailed information about the wire's performance, facilitating better decision-making regarding material selection and manufacturing processes.

Applications Across Industries

Wire reverse bending test machines find applications across various industries, including automotive, aerospace, construction, and electrical. In the automotive sector, for instance, wire is used in the production of springs, cables, and other components that require high fatigue resistance. Similarly, in the aerospace industry, where safety and reliability are of utmost importance, these machines help ensure that wire used in critical systems meets stringent safety standards. In construction, reinforcing wires used in concrete structures must also be tested for reliability, making reverse bending tests essential for ensuring structural integrity.

The Future of Wire Testing

As technology continues to evolve, so too does the capabilities of wire reverse bending test machines. The integration of artificial intelligence and machine learning into testing processes promises to enhance predictive analytics, allowing manufacturers to foresee potential failures and address them proactively. Moreover, advancements in automation can streamline testing procedures, reducing human error and increasing efficiency.

Conclusion

In conclusion, the wire reverse bending test machine is an invaluable tool for quality assurance in wire manufacturing. By providing essential data on the mechanical properties of wire products, these machines help ensure that manufacturers meet industry standards and regulations. As industries continue to demand higher performance and reliability, the importance of robust testing methods like reverse bending tests will only grow, solidifying their role as vital components in the manufacturing process. Whether for safety, compliance, or performance optimization, investing in advanced wire testing technology is a commitment to quality and excellence in manufacturing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy