јун . 13, 2024 14:13

Back to list

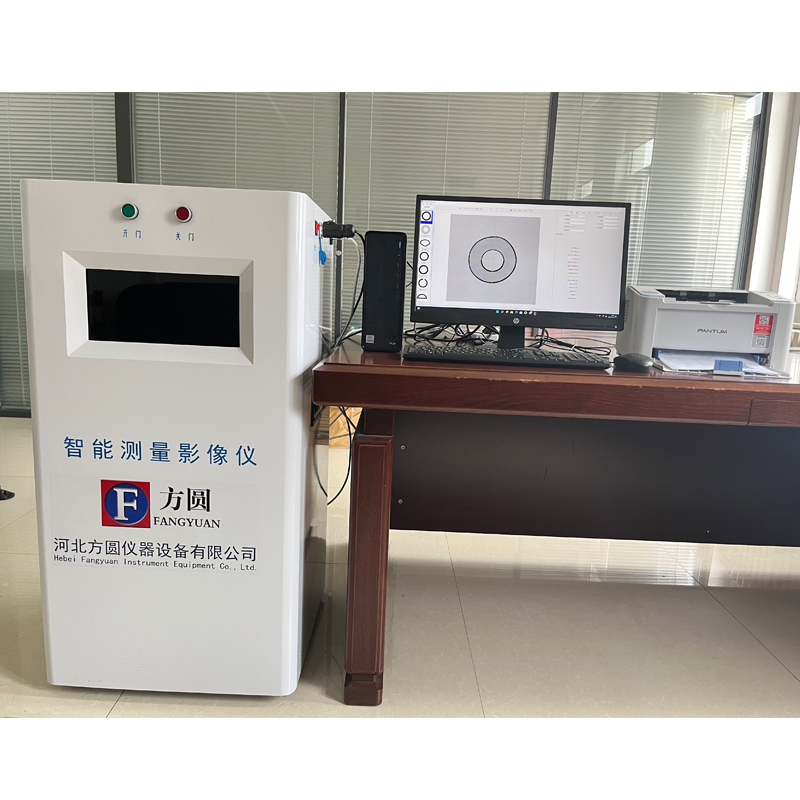

Short Sentence Assessing Imager Manufacturing Facilities

Measuring Imager Factories A Comprehensive Guide

In the realm of technology, imaging factories play a pivotal role in transforming raw data into detailed images that are paramount in various industries, such as healthcare, security, and research. These factories are equipped with state-of-the-art machinery and software designed to cater to the unique requirements of their respective industries.

The performance of these imaging factories is usually measured using specific parameters that highlight their operational efficiency, technological advancements, and quality output. The following sections delve deeper into the various aspects that need to be considered while measuring imager factories.

1. Production Output The primary measure of success for any factory is its productivity. To gauge this aspect, one must evaluate the number of images produced per unit time, considering factors like production rate, downtime, and maintenance intervals. Additionally, the consistency and quality of the images produced are vital indicators of the factory's overall performance.

2. Equipment Performance Sophisticated imaging equipment, such as digital cameras, microscopes, and spectrometers, form the backbone of these factories. Assessing the performance of these instruments not only helps in maintaining them in optimal working condition but also ensures that the images produced align with the required specifications. Key metrics to consider include resolution, sensitivity, dynamic range, and signal-to-noise ratio.

3. Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis

Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis measuring imager factories. Evaluating the integration capabilities of these software systems is essential, as they often interface with other critical systems within the factory. Factors such as ease of use, compatibility, scalability, and ability to integrate third-party tools greatly influence the overall performance of an imaging factory.

4. Quality Control Ensuring the quality of images produced is of utmost importance, as it directly impacts decision-making processes across industries. Regular quality control checks, coupled with statistical process control techniques, enable manufacturers to identify and address potential issues proactively. Metrics such as defect detection rate, pixel accuracy, and image uniformity provide insights into the effectiveness of the quality control measures employed by the factory.

5. Regulatory Compliance Imaging factories processing sensitive data must adhere to strict regulatory standards and guidelines, such as HIPAA (Health Insurance Portability and Accountability Act) in healthcare or FDA (Food and Drug Administration) regulations in pharmaceuticals. Failing to comply with these standards can result in severe penalties and damage to the factory's reputation. Therefore, assessing the factory's compliance record and understanding the associated risks is vital.

In conclusion, measuring imager factories involves evaluating various aspects, including production output, equipment performance, software integration, quality control, and regulatory compliance. By focusing on these areas, stakeholders can gain a comprehensive understanding of the factory's capabilities and work towards enhancing its overall performance.

measuring imager factories. Evaluating the integration capabilities of these software systems is essential, as they often interface with other critical systems within the factory. Factors such as ease of use, compatibility, scalability, and ability to integrate third-party tools greatly influence the overall performance of an imaging factory.

4. Quality Control Ensuring the quality of images produced is of utmost importance, as it directly impacts decision-making processes across industries. Regular quality control checks, coupled with statistical process control techniques, enable manufacturers to identify and address potential issues proactively. Metrics such as defect detection rate, pixel accuracy, and image uniformity provide insights into the effectiveness of the quality control measures employed by the factory.

5. Regulatory Compliance Imaging factories processing sensitive data must adhere to strict regulatory standards and guidelines, such as HIPAA (Health Insurance Portability and Accountability Act) in healthcare or FDA (Food and Drug Administration) regulations in pharmaceuticals. Failing to comply with these standards can result in severe penalties and damage to the factory's reputation. Therefore, assessing the factory's compliance record and understanding the associated risks is vital.

In conclusion, measuring imager factories involves evaluating various aspects, including production output, equipment performance, software integration, quality control, and regulatory compliance. By focusing on these areas, stakeholders can gain a comprehensive understanding of the factory's capabilities and work towards enhancing its overall performance.

Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis

Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis Software Integration Advanced software platforms play a crucial role in managing the entire imaging process, from image acquisition to analysis measuring imager factories. Evaluating the integration capabilities of these software systems is essential, as they often interface with other critical systems within the factory. Factors such as ease of use, compatibility, scalability, and ability to integrate third-party tools greatly influence the overall performance of an imaging factory.

4. Quality Control Ensuring the quality of images produced is of utmost importance, as it directly impacts decision-making processes across industries. Regular quality control checks, coupled with statistical process control techniques, enable manufacturers to identify and address potential issues proactively. Metrics such as defect detection rate, pixel accuracy, and image uniformity provide insights into the effectiveness of the quality control measures employed by the factory.

5. Regulatory Compliance Imaging factories processing sensitive data must adhere to strict regulatory standards and guidelines, such as HIPAA (Health Insurance Portability and Accountability Act) in healthcare or FDA (Food and Drug Administration) regulations in pharmaceuticals. Failing to comply with these standards can result in severe penalties and damage to the factory's reputation. Therefore, assessing the factory's compliance record and understanding the associated risks is vital.

In conclusion, measuring imager factories involves evaluating various aspects, including production output, equipment performance, software integration, quality control, and regulatory compliance. By focusing on these areas, stakeholders can gain a comprehensive understanding of the factory's capabilities and work towards enhancing its overall performance.

measuring imager factories. Evaluating the integration capabilities of these software systems is essential, as they often interface with other critical systems within the factory. Factors such as ease of use, compatibility, scalability, and ability to integrate third-party tools greatly influence the overall performance of an imaging factory.

4. Quality Control Ensuring the quality of images produced is of utmost importance, as it directly impacts decision-making processes across industries. Regular quality control checks, coupled with statistical process control techniques, enable manufacturers to identify and address potential issues proactively. Metrics such as defect detection rate, pixel accuracy, and image uniformity provide insights into the effectiveness of the quality control measures employed by the factory.

5. Regulatory Compliance Imaging factories processing sensitive data must adhere to strict regulatory standards and guidelines, such as HIPAA (Health Insurance Portability and Accountability Act) in healthcare or FDA (Food and Drug Administration) regulations in pharmaceuticals. Failing to comply with these standards can result in severe penalties and damage to the factory's reputation. Therefore, assessing the factory's compliance record and understanding the associated risks is vital.

In conclusion, measuring imager factories involves evaluating various aspects, including production output, equipment performance, software integration, quality control, and regulatory compliance. By focusing on these areas, stakeholders can gain a comprehensive understanding of the factory's capabilities and work towards enhancing its overall performance. Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy