wire fatigue bending test equipment manufacturer and supplier for quality assurance

Wire Repeated Bending Test Machine An Overview of Its Importance and Functionality

In the realm of materials testing, the wire repeated bending test machine holds significant importance. This specialized equipment is designed to assess the performance and durability of wires under repeated bending stress. Such testing is crucial in various industries, including construction, automotive, electronics, and manufacturing, where the integrity of wire components can directly influence the safety and reliability of the final products.

Understanding the Wire Repeated Bending Test

The wire repeated bending test involves subjecting a specimen wire to a series of bending cycles. The primary goal is to simulate real-world conditions where wires may be subjected to repeated bending and flexing over their lifespan. By applying a predetermined amount of strain, engineers can measure the wire's fatigue resistance, assess its mechanical properties, and predict its failure point.

This test is particularly important for applications where wires are frequently bent, such as in electrical connectors, springs, and various other components. The repeated bending can lead to fatigue failure—a phenomenon where materials crack or break after undergoing numerous cycles of stress, even if the individual stress levels are below the material's ultimate tensile strength.

Key Features of the Wire Repeated Bending Test Machine

1. Precision and Control Modern wire repeated bending test machines are equipped with advanced control systems that allow precise adjustments to bending angles, frequencies, and cycles. This precision ensures that tests can accurately replicate potential real-life scenarios.

2. Data Acquisition Systems These machines often come with integrated data acquisition systems that monitor key parameters during testing. This can include load, displacement, and the number of cycles completed. Such data is invaluable for analyzing the performance of various wire materials under stress.

wire repeated bending test machine factory

3. Versatility The design of the test machine enables it to accommodate wires of different materials, diameters, and configurations. This versatility makes it an essential tool for manufacturers looking to evaluate a wide range of wire products.

4. User-Friendly Interface Many machines are equipped with software that provides a user-friendly interface for setting up tests, monitoring progress, and analyzing results. This software often includes capabilities for generating detailed reports, which can be crucial for quality assurance and compliance with industry standards.

Applications of the Wire Repeated Bending Test Machine

In the automotive industry, for example, wires are used in various applications including electrical systems, safety mechanisms, and structural components. Testing these wires under conditions that mimic operational stresses helps ensure that they will perform reliably over time, thus enhancing vehicle safety.

In the construction sector, wires are integral to reinforced structures. Their performance during bending tests can guide engineers in selecting the appropriate materials for specific applications, ensuring that buildings and infrastructure are safe and durable.

Additionally, in electronics manufacturing, wire connectors and other components must withstand repeated stress without failing. The use of a repeated bending test machine enables manufacturers to produce more reliable products, thereby increasing consumer confidence and reducing warranty claims.

Conclusion

The wire repeated bending test machine is an indispensable tool in material testing, contributing to advancements in multiple industries where performance and reliability are non-negotiable. By accurately simulating real-world conditions and providing comprehensive data on wire behavior under stress, manufacturers can make informed decisions about material selection and product design. This not only enhances product quality but also plays a critical role in ensuring consumer safety. As industries continue to evolve, the importance of such testing machines will only grow, underpinning innovation and excellence in product development.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

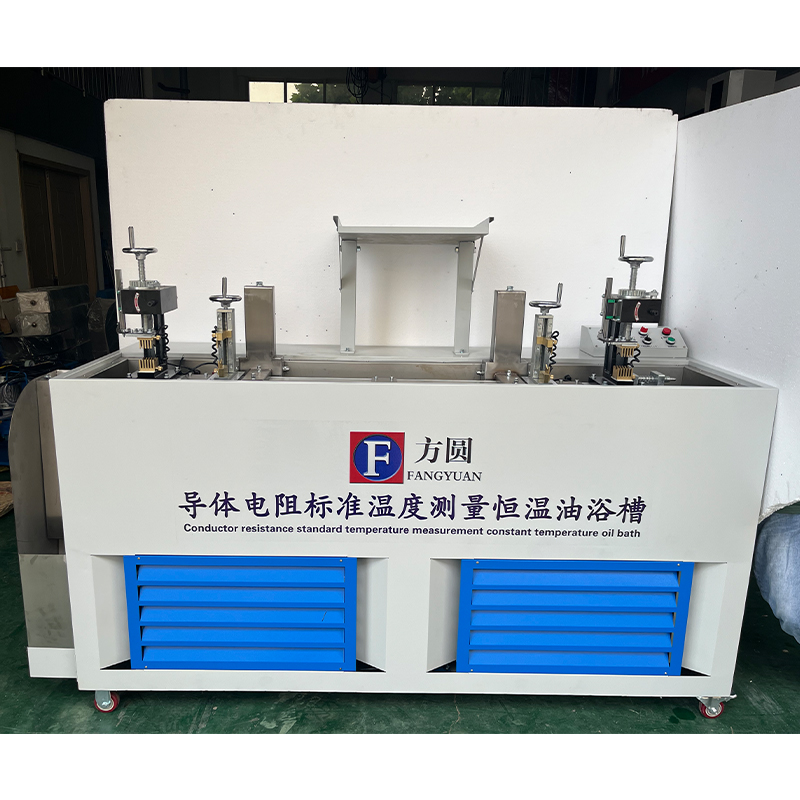

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy