projector 9-point measurement factory

The 9-Point Measurement Factory Revolutionizing Projections for Precision

In the ever-evolving landscape of industrial manufacturing, precision and accuracy are paramount. One of the most innovative and effective tools in achieving these standards is the 9-point measurement factory, specifically designed for projectors and other optical instruments. This method not only enhances productivity but also ensures the meticulous accuracy required in various applications ranging from automotive to aerospace, and from electronics to textiles.

Understanding 9-Point Measurement

The 9-point measurement technique involves taking measurements at nine specific points across a given surface or object. This approach provides a comprehensive understanding of the dimensional properties and ensures a high level of accuracy in evaluating the object’s geometry. In a typical factory setting, this measurement process is facilitated by high-precision projectors, which use optical technology to project an image of the measured object onto a screen where precise measurements can be taken.

The Benefits of 9-Point Measurement in Manufacturing

1. Enhanced Accuracy One of the most significant advantages of the 9-point measurement method is its ability to provide highly accurate data. By assessing nine separate locations, any anomalies or defects in shape can be identified quickly and addressed before they escalate into more significant issues. This level of detail is crucial in industries like aerospace, where even minute discrepancies can lead to severe consequences.

2. Improved Efficiency The 9-point method streamlines the measurement process. Instead of taking multiple random points without a systematic approach, this methodology employs a structured process that leads to quicker results. Manufacturers can utilize these findings to refine their production processes, ultimately boosting overall efficiency and productivity.

3. Cost-Effectiveness By minimizing errors and enhancing the precision of the manufacturing process, companies can significantly reduce waste and rework. The initial investment in a measurement system based on this methodology is offset by the long-term savings in materials and labor costs. Additionally, by ensuring quality products from the outset, companies can maintain customer satisfaction and loyalty.

Implementing the 9-Point Measurement Process

projector 9-point measurement factory

The successful implementation of the 9-point measurement process within a factory setting requires both proper training and cutting-edge equipment. Operators must be well-acquainted with the measurement devices and methodologies to ensure accurate data is collected.

1. Selection of Equipment Choosing the right projector is critical. Modern projectors equipped with advanced optics and digital measurement capabilities can greatly enhance the speed and accuracy of the measurement process. Additionally, investing in quality software for analysis can help in streamlining the data collection process and facilitating easier interpretation of results.

2. Training Personnel Employees should undergo rigorous training to familiarize themselves with the equipment and the 9-point measurement process. This includes not only handling the equipment but also understanding the underlying principles of measurement and error analysis.

3. Continuous Monitoring and Evaluation Once implemented, the 9-point measurement system should be continuously monitored and evaluated for improvements and adaptations. Regular assessments can help in identifying potential areas for calibration and can also lead to the discovery of new best practices within the measurement process.

Future Prospects

As technology progresses, the scope of the 9-point measurement factory will expand. With the integration of Artificial Intelligence (AI) and machine learning, real-time data processing and analysis will become increasingly feasible. This will not only further enhance the accuracy of measurements but also allow for predictive maintenance of the measurement equipment, reducing downtime and increasing the overall efficiency of the production process.

Conclusion

The 9-point measurement factory represents a significant advancement in precision measurement technology. With its manifold advantages, including enhanced accuracy, increased efficiency, and cost savings, it is swiftly becoming an indispensable part of modern manufacturing. As industries continue to pursue higher standards of quality and efficiency, the role of sophisticated measurement techniques will only grow, pushing forward the boundaries of what is possible in manufacturing. Embracing such innovations will undoubtedly lead to a new era of precision engineering, ensuring that industries remain competitive in a rapidly changing global market.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

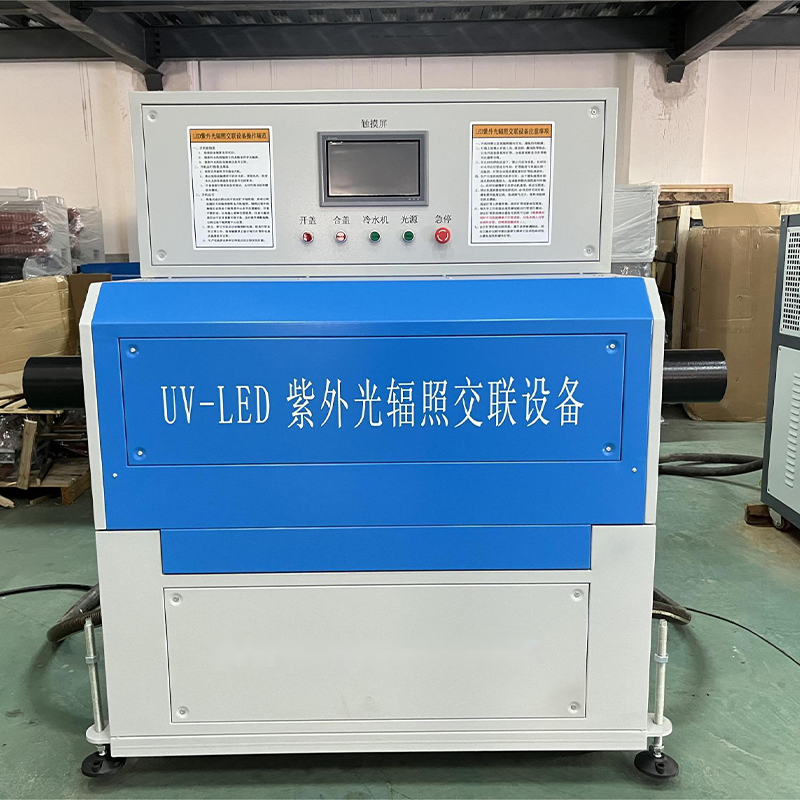

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy