Leading Manufacturers of Standard Resistance Testing Equipment for Accurate Measurements

Understanding Standard Resistance Tester Manufacturers

In today's fast-paced technological world, the importance of accurate and efficient testing instruments cannot be overstated. Among these, standard resistance testers play a vital role in ensuring the reliability of electrical components and systems. These instruments are crucial for industries, utilities, and laboratories that deal with the testing and maintenance of electrical systems. This article delves into the significance of standard resistance testers and highlights the key aspects to consider when looking for a reliable manufacturer.

What is a Standard Resistance Tester?

A standard resistance tester, also known as a micro-ohm meter, is an electronic device designed to measure small resistances very accurately. These testers are usually used to evaluate the resistance of electrical contacts, insulation, and various parts of electrical equipment. The measurement of resistance is essential for determining the integrity and performance of electrical systems, helping prevent failure and ensuring safety.

Key Applications

Standard resistance testers find applications in various fields, including electrical utility maintenance, manufacturing, and research laboratories. In electrical utility maintenance, they are used to measure the contact resistances in circuit breakers, bus bars, and joints. In manufacturing, they help in quality control by ensuring that components meet specified resistance levels. For research laboratories, precise resistance measurements are critical for experimental validation and the development of new technologies.

Choosing a Reliable Manufacturer

When it comes to selecting a standard resistance tester manufacturer, several factors need to be taken into account to ensure the chosen equipment meets your needs

1. Quality and Accuracy High-quality testers must provide accurate measurements. Reputable manufacturers invest in advanced technology and quality control processes to ensure that their products meet industry standards.

2. Variety of Products The manufacturer should ideally offer a wide range of resistance testers with various features and measurement ranges. This variety ensures that customers can choose a product that best fits their specific application requirements.

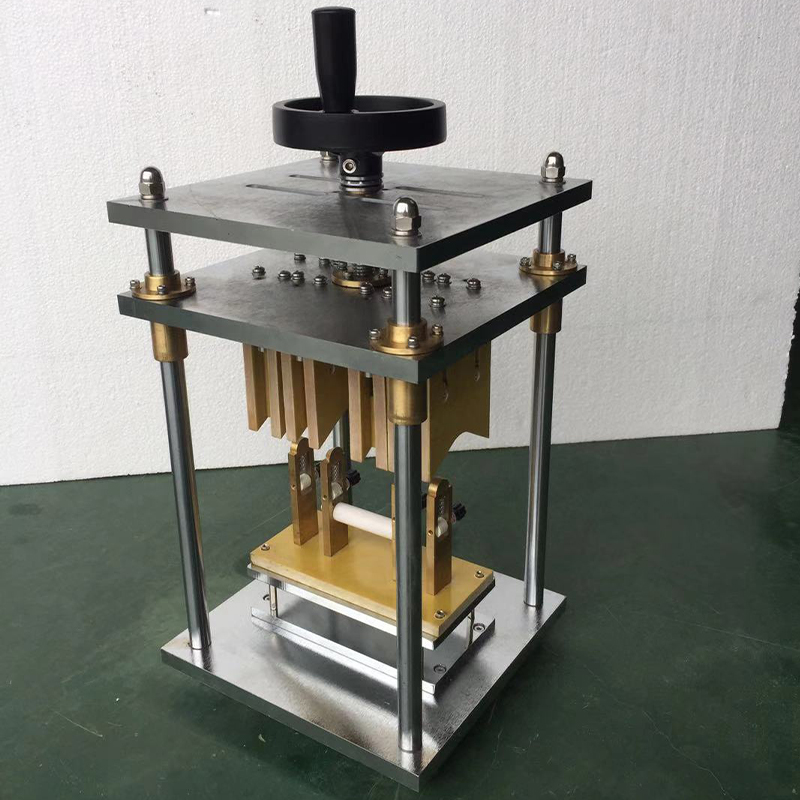

standard resistance tester manufacturer

3. Calibration and Compliance Check if the manufacturer provides calibration services certified by recognized standards. Compliance with international standards, such as ISO and IEC, is crucial for the reliability of measuring instruments.

4. Support and Warranty Good customer support is vital for troubleshooting and maintenance. It's also essential to verify the warranty policies of the manufacturer, providing you with peace of mind regarding after-sales service.

5. Reputation and Reviews Researching the manufacturer's reputation in the industry and looking for customer reviews can offer insights into the reliability of their products and services. Manufacturers with a strong track record are typically more trustworthy.

6. Technological Advancements The best manufacturers are those that embrace innovation. Look for manufacturers that regularly update their products with the latest technology, ensuring high performance and user-friendly operation.

Leading Manufacturers in the Industry

Some of the well-known names in the standard resistance tester manufacturing industry include Fluke, Megger, and AEMC Instruments. These companies have established solid reputations for producing high-quality measuring instruments and providing excellent customer service.

- Fluke is renowned for its emphasis on ruggedness and precision, catering to both industrial and commercial markets. - Megger specializes in insulation testing and offers a variety of electrical testing equipment, including resistance testers. - AEMC Instruments is notable for its commitment to innovation and has a comprehensive line of testers suited for different applications.

Conclusion

In conclusion, standard resistance testers are essential tools in ensuring the reliability and safety of electrical systems. When selecting a manufacturer, it is crucial to consider factors such as quality, variety, compliance with standards, support, and reputation. By investing in a high-quality resistance tester from a reliable manufacturer, industries can enhance their testing capabilities, ensure operational efficiency, and ultimately prevent costly failures. As technology continues to evolve, staying informed about the latest advancements in resistance testing will help organizations maintain their edge in the competitive landscape.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy