Leading Manufacturers of Tensile Testing Machines for Material Strength Analysis

The Importance of Tensile Testing Machines in Material Science

Tensile testing is a crucial process in material science, providing essential data about the mechanical properties of various materials. From metals and plastics to composites and textiles, understanding how materials behave under tension is vital for engineers and manufacturers. Central to this testing process are tensile testing machines, designed specifically to assess the tensile strength, elongation, and overall durability of materials. In this article, we will explore the significance of tensile testing machines, their components, and their application across various industries.

What is a Tensile Testing Machine?

A tensile testing machine, also known as a universal testing machine, is a device used to test the tensile strength of materials by applying a controlled tensile load until the material fails. Typically, the machine consists of several key components a load frame, a load cell, a crosshead, grips, and a control system. The load frame is a robust structure that supports the material specimen during testing, while the load cell measures the force applied. The crosshead moves in a controlled manner to stretch the material, and the grips hold the specimen securely in place.

Why is Tensile Testing Important?

Tensile testing provides critical information about a material's properties, including yield strength, ultimate tensile strength (UTS), modulus of elasticity, and percent elongation. These properties are essential for manufacturers making decisions regarding material selection for various applications. For instance, in the aerospace industry, materials must withstand significant stress while maintaining structural integrity. Tensile testing ensures that the materials used in aircraft components can meet these demands.

Moreover, tensile testing helps in quality control and assurance. Manufacturers can use tensile test results to verify that their materials meet specific standards and specifications. This is particularly important in regulated industries, such as construction and automotive manufacturing, where material failure can lead to catastrophic consequences.

Applications Across Industries

tensile tests machine manufacturer

Tensile testing machines have widespread applications across various sectors. In construction and civil engineering, they are used to test the strength of concrete, steel, and other building materials. In the automotive industry, tensile tests are vital for evaluating the durability of components like bumpers, chassis parts, and safety equipment. Likewise, in the textile industry, tensile testing machines help determine the strength and elasticity of fabrics, ensuring that clothing and upholstery can withstand everyday wear and tear.

The medical industry also benefits from tensile testing. Biodegradable materials and medical devices, such as sutures and implants, undergo rigorous testing to ascertain their performance and safety. Even in the electronics sector, materials used in wiring and casings are assessed for their tensile strength to ensure reliability and performance under various conditions.

The Future of Tensile Testing Machines

With advancements in technology, tensile testing machines are becoming more sophisticated. Modern machines are equipped with computer software that allows for more accurate data collection and analysis. This software can generate stress-strain curves, which provide visual representations of a material's mechanical properties. Additionally, the integration of automation in tensile testing machines enhances efficiency and reproducibility, paving the way for more streamlined testing processes.

Furthermore, the rise of high-performance materials, such as graphene and advanced composites, necessitates more precise and comprehensive testing. As industries continue to evolve, the demand for high-quality tensile testing machines will undoubtedly increase, emphasizing their role in ensuring material performance and safety.

Conclusion

In summary, tensile testing machines play a pivotal role in material science, providing valuable insights into the mechanical properties of materials used in various industries. From ensuring safety and quality to driving innovation, the importance of these machines cannot be overstated. As technology continues to advance, the potential for enhanced tensile testing methodologies will undoubtedly contribute to the development of stronger, more reliable materials in the future. Whether for aerospace, automotive, or medical applications, tensile testing remains a cornerstone of material evaluation and selection.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

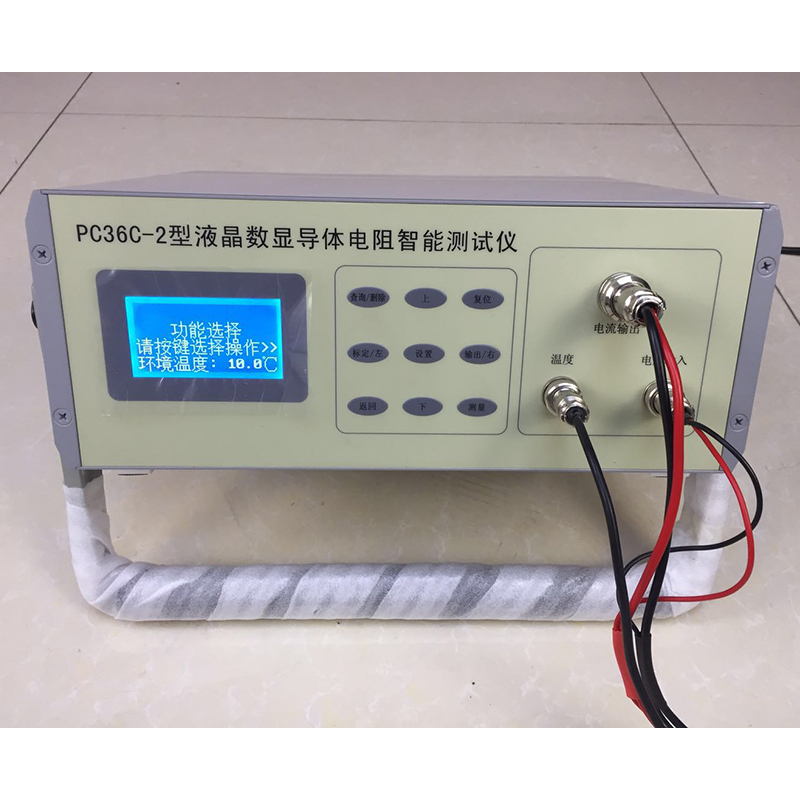

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy