5kN Universal Tensile Testing Machine for Material Strength Assessment and Analysis

Understanding the 5kN Universal Tensile Tester A Comprehensive Overview

The 5kN universal tensile tester is a crucial piece of equipment in material testing laboratories, playing an essential role in assessing the mechanical properties of various materials. This device is designed to apply tensile loads to materials and measure their response until failure. As engineering and manufacturing demand increasingly sophisticated materials, the relevance of tensile testing has never been more significant.

What is a Universal Tensile Tester?

A universal tensile tester is an apparatus used for determining the tensile strength, yield strength, elongation, and other mechanical properties of materials. The “5kN” designation refers to the machine’s maximum load capacity, which is 5 kilonewtons (kN). This makes it suitable for testing a wide range of materials such as metals, plastics, rubber, textiles, and composites.

Key Features of the 5kN Universal Tensile Tester

1. Load Capacity With a maximum load of 5kN, this tester is ideal for many small and medium-sized specimens, providing accurate and efficient results. This makes it particularly advantageous for educational institutions and small manufacturing units where diverse material testing is required.

2. Precision and Accuracy The machine comes with high-precision load cells and displacement transducers, ensuring accurate measurements during testing. It can produce reliable data that are crucial for quality control and product development.

3. User-Friendly Interface Modern tensile testers often feature digital interfaces that simplify operation. Users can easily set parameters, monitor the test in real-time, and record the results, making the machine accessible to both experienced technicians and newcomers.

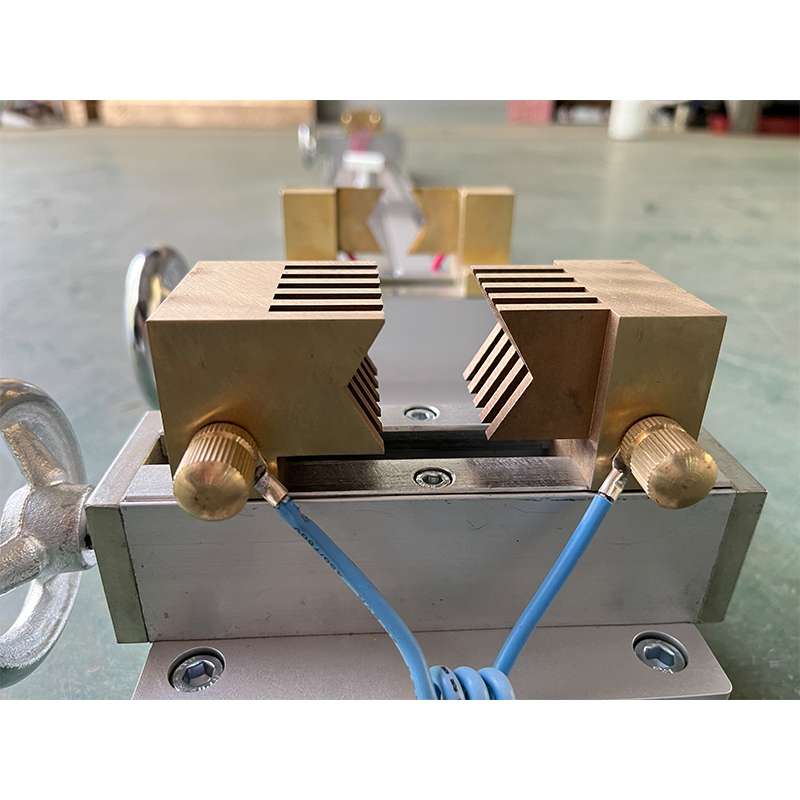

4. Versatile Testing Options In addition to standard tensile testing, many 5kN testers can perform optional tests such as compression, bending, and shear tests. This versatility is due to interchangeable grips and fixtures, allowing users to adapt the tester for specific testing needs.

5kn universal tensile tester

The Testing Process

The testing process typically involves preparing a specimen, which is cut and shaped per standardized dimensions for consistent results. The specimen is then placed into the tester's grips, which can be pneumatic, hydraulic, or manually operated, depending on the machine’s design.

Once the specimen is secured, the machine applies a controlled tensile load while monitoring both the load applied and the elongation of the material. Data is collected until the specimen fails, allowing researchers and engineers to evaluate the material’s performance. Key data points include the maximum load before failure, ductility (percentage elongation), and stress-strain characteristics.

Applications and Importance

The applications of a 5kN universal tensile tester span across multiple industries including aerospace, automotive, construction, and textiles. In aerospace, for instance, understanding the tensile properties of materials is vital for safety and performance. Similarly, in automotive manufacturing, tensile testing helps in evaluating materials used in vehicle components, ensuring they meet industry regulations and performance standards.

Moreover, this testing is not just crucial for product development and quality control but is also instrumental in research applications. Scientists and engineers utilize tensile testing data to inform new material development, enhance product longevity, and improve safety measures.

Conclusion

In conclusion, the 5kN universal tensile tester is an invaluable tool in the realm of material science and engineering. Its precise measurement capabilities, user-friendly interface, and versatility make it ideal for a wide array of applications. By providing critical insights into the mechanical properties of materials, it aids in the advancement of technology and ensures that products meet the necessary standards of safety and reliability. As industries continue to evolve, the role of such testing equipment will undoubtedly expand, further emphasizing the importance of material testing in our everyday lives.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy