Suppliers of Cross-Linked Cable Machinery for Improved Production Efficiency

The Rise of Cable Cross-Linked Machine Suppliers A Comprehensive Overview

In the modern industrial landscape, the demand for advanced manufacturing processes and high-quality products has surged dramatically. Among the myriad of innovations, cable cross-linking technology stands out as a crucial component in various sectors, including electronics, automotive, and telecommunications. This article explores the topic of cable cross-linked machine suppliers and the impact they have on the industry.

Understanding Cable Cross-Linking

Cable cross-linking is a process that enhances the properties of polymer materials, enabling them to withstand higher temperatures, resist chemicals, and improve overall durability. This process involves the bonding of polymer chains, which increases the material's strength and resistance to deformation. The end products, such as cross-linked polyethylene (PEX) and other specialized cables, are incredibly versatile and find applications in both residential and commercial settings.

The Importance of Suppliers

As the demand for cross-linked cables continues to grow, the role of cable cross-linked machine suppliers has become more vital. These suppliers provide the necessary machinery and technologies needed for the production of high-quality cross-linked cables. They play an essential role in ensuring that manufacturers can meet rigorous industry standards while maintaining efficiency in their production processes.

Key Factors in Choosing a Supplier

When selecting a cable cross-linked machine supplier, several factors come into play

1. Quality and Reliability The supplier's track record for delivering high-quality machinery is paramount. Manufacturers need to invest in machines that are durable, reliable, and efficient to ensure consistent production quality.

2. Technological Innovation The industry is continually evolving, with advancements in technology that can significantly enhance manufacturing processes. Suppliers that are at the forefront of innovation can offer state-of-the-art machines that allow for faster production times and improved product quality.

3. Customization Options Different manufacturers may have varying specifications and requirements. Suppliers that offer tailored solutions and a range of customization options can cater to specific needs, enhancing the value of the investment.

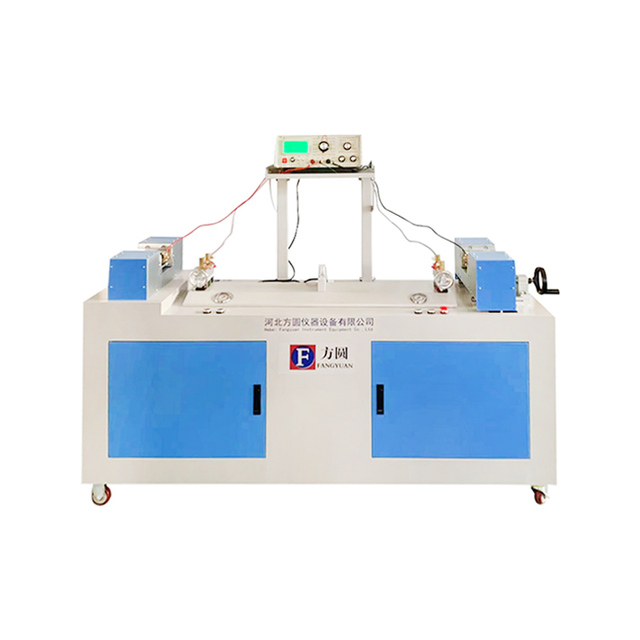

cable cross-linked machine supplier

4. After-Sales Support The importance of reliable after-sales service cannot be overstated. Suppliers should offer comprehensive support, including maintenance, training, and troubleshooting, to ensure that manufacturers can maximize the lifespan and efficiency of their machinery.

5. Cost-Effectiveness While quality and reliability are crucial, the cost is also a significant factor. Suppliers need to provide competitive pricing without compromising on the quality of their machines.

Trends in the Cable Cross-Linked Machine Market

The cable cross-linked machine market is witnessing several noteworthy trends. First, the increasing demand for high-performance materials in the automotive and electronics sectors is driving innovation in manufacturing processes. Many manufacturers are exploring eco-friendly options, leading to the development of machines that support sustainable practices.

Furthermore, automation is becoming a key focus in the industry. Suppliers that incorporate automation and smart technologies into their machines significantly enhance productivity and reduce human error, making the manufacturing process more efficient.

Challenges Facing Suppliers

Despite the positive outlook, cable cross-linked machine suppliers face several challenges. One major challenge is the evolving regulatory landscape that requires adherence to strict guidelines regarding material safety and environmental impact. Suppliers must stay compliant with these regulations while meeting the demands of their clients.

Additionally, global supply chain disruptions can affect the procurement of materials and components, leading to potential delays in manufacturing and delivery. Suppliers need to be agile and resourceful in navigating these challenges to maintain their competitive edge.

Conclusion

In conclusion, cable cross-linked machine suppliers play a pivotal role in the manufacturing landscape, driving innovation and enabling companies to produce high-quality cables that meet the needs of various industries. As technology continues to advance, the importance of selecting the right supplier becomes increasingly critical for manufacturers seeking to enhance their production capabilities. By focusing on quality, technological innovation, customization, and robust after-sales support, suppliers can ensure their clients succeed in a highly competitive market. The continued development and refinement of cable cross-linking technology will undoubtedly solidify its place as a cornerstone of modern manufacturing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy