jan . 31, 2025 01:13

Back to list

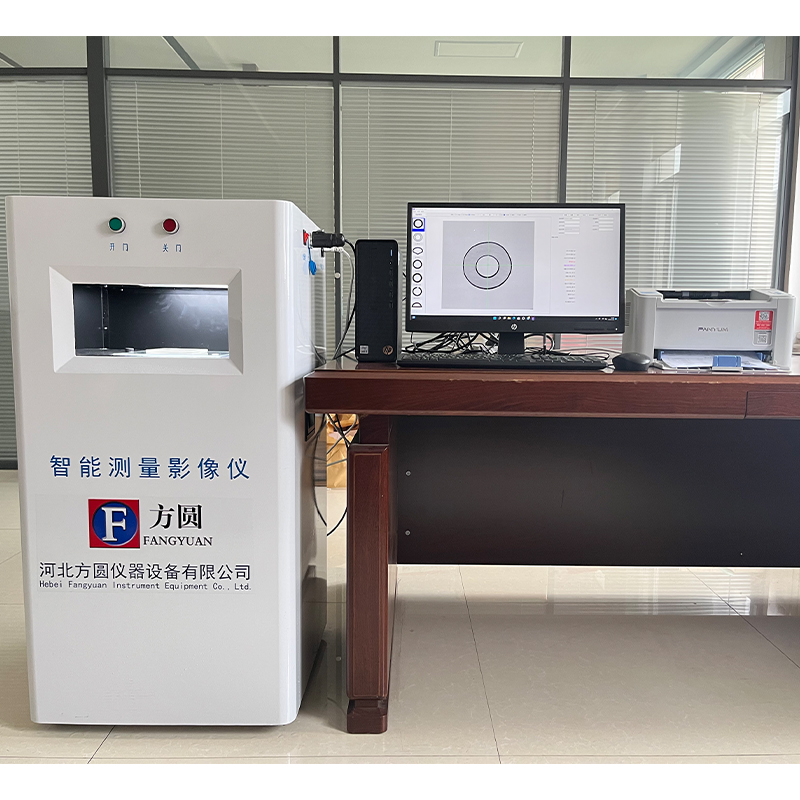

custom machine to measure resistances

In the diverse world of electronics, measuring resistance accurately is paramount. Industries and researchers are continually seeking more precise methods to ensure quality and efficiency. A custom machine crafted to measure resistances offers unparalleled benefits, providing the definitive solution to many obstacles faced in resistance measurement.

The customization process is inherently collaborative, drawing insights from the end-user’s environment and specific challenges. By analyzing workflow, material properties, and environmental factors, the customization process results in a device that is not only precise but also robust enough to withstand industry-specific conditions. For example, in environments with significant electromagnetic interference, the custom machine might feature enhanced shielding and filtering capabilities to mitigate potential disruptions. Moreover, tapping into emerging trends such as IoT integration and machine learning, these machines can also future-proof operations. Imagine a scenario where resistance measurements are automatically fed into a central database, analyzed for trends, and used to predict equipment maintenance needs, avoiding downtime before it even occurs. This kind of foresight transforms resistance measurement from a basic task to a strategic tool that can inform broader operational decisions. Integrating a custom resistance measuring machine into a facility is not merely about enhancing measurement precision. It’s about investing in reliability, efficiency, and a tailored fit to the unique needs of the industry. The value derived from these machines is not just in their immediate output but in the long-term gain they contribute to the operational ecosystem they serve. For those ready to elevate their resistance measurement practices, the journey starts with an in-depth consultation with a trusted provider, ensuring that the machine aligns perfectly with current and future demands. Such an investment in custom technology equips an organization not only with a competitive advantage but also positions it strongly in an economy increasingly driven by precision and customization. In today's fast-paced and technologically advanced world, there is no substitute for precision and reliability, and a custom machine to measure resistances stands as a testament to what is possible when innovation meets expertise.

The customization process is inherently collaborative, drawing insights from the end-user’s environment and specific challenges. By analyzing workflow, material properties, and environmental factors, the customization process results in a device that is not only precise but also robust enough to withstand industry-specific conditions. For example, in environments with significant electromagnetic interference, the custom machine might feature enhanced shielding and filtering capabilities to mitigate potential disruptions. Moreover, tapping into emerging trends such as IoT integration and machine learning, these machines can also future-proof operations. Imagine a scenario where resistance measurements are automatically fed into a central database, analyzed for trends, and used to predict equipment maintenance needs, avoiding downtime before it even occurs. This kind of foresight transforms resistance measurement from a basic task to a strategic tool that can inform broader operational decisions. Integrating a custom resistance measuring machine into a facility is not merely about enhancing measurement precision. It’s about investing in reliability, efficiency, and a tailored fit to the unique needs of the industry. The value derived from these machines is not just in their immediate output but in the long-term gain they contribute to the operational ecosystem they serve. For those ready to elevate their resistance measurement practices, the journey starts with an in-depth consultation with a trusted provider, ensuring that the machine aligns perfectly with current and future demands. Such an investment in custom technology equips an organization not only with a competitive advantage but also positions it strongly in an economy increasingly driven by precision and customization. In today's fast-paced and technologically advanced world, there is no substitute for precision and reliability, and a custom machine to measure resistances stands as a testament to what is possible when innovation meets expertise.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy