Exploring Factories for Digital Measurement Projectors and Their Innovations in Technology

The Rise of Digital Measurement Projectors A Glimpse into the Future

In the realm of precision measurement, digital measurement projectors represent a groundbreaking innovation that has transformed how industries approach quality control and design verification. These sophisticated instruments combine advanced optics, digital technology, and user-friendly interfaces to provide unparalleled accuracy, reliability, and efficiency in various applications, from manufacturing to design. The increase in demand for high-quality production processes has led to the growth of digital measurement projector factories, which cater to diverse industries globally.

Understanding Digital Measurement Projectors

Digital measurement projectors, also known as optical comparators, utilize a system of lenses to project magnified silhouettes of an object onto a screen. This projection allows operators to directly compare the part being measured with established specifications or CAD designs. The digital integration enhances traditional optical methods by providing real-time measurements, data storage, and advanced analysis capabilities.

One of the key benefits of digital measurement projectors is their ability to provide precise measurements quickly. By employing advanced image processing technology, these devices can automatically analyze features such as diameters, angles, and contours, significantly reducing the time required for manual measurement processes. This efficiency not only accelerates production cycles but also helps in minimizing human error, thereby ensuring higher quality standards.

The Growth of Digital Measurement Projector Factories

As industries increasingly recognize the importance of precision measurement, the demand for digital measurement projectors has surged. This has led to the establishment of numerous factories dedicated to their production. These factories harness cutting-edge technology and innovation to manufacture a range of digital measurement projectors, catering to various industries including automotive, aerospace, electronics, and medical devices.

Investments in automation and robotics within these factories have also enhanced the production process. Automated assembly lines ensure consistency and precision in manufacturing, while advanced quality control measures guarantee that each projector meets strict industry standards. Additionally, the integration of IoT (Internet of Things) technology allows for real-time monitoring of production processes, further improving efficiency and product quality.

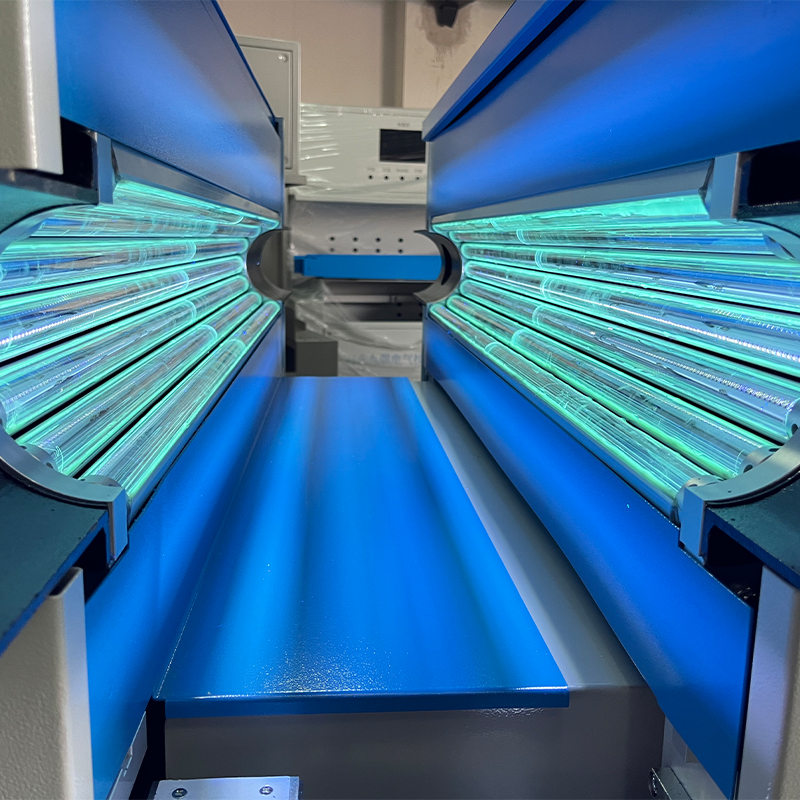

digital measurement projector factories

Innovations in Design and Functionality

Recent advancements in technology have led to the evolution of digital measurement projectors with enhanced features. Manufacturers are now incorporating capabilities such as touchscreen interfaces, improved software for data analysis, and connectivity options that allow for easier integration into existing production environments. Some modern projectors even offer 3D measurement capabilities, enabling users to evaluate complex geometries that were previously challenging to assess using traditional methods.

Moreover, the focus on user experience has resulted in the development of intuitive control systems, reducing the learning curve for operators. This is particularly beneficial for small to medium-sized enterprises (SMEs) that may not have dedicated quality control personnel. Enhanced training resources and support services offered by manufacturers also contribute to the effective utilization of these advanced measurement tools.

Challenges and Future Trends

Despite the growth and advancement of digital measurement projector factories, challenges remain. The market is becoming increasingly competitive, which puts pressure on manufacturers to continuously innovate and reduce costs. Additionally, as industries push for more sustainable practices, factories must find ways to minimize their environmental impact during production processes.

Looking to the future, the integration of artificial intelligence (AI) and machine learning within digital measurement projectors is expected to revolutionize their functionality further. These technologies could enable predictive analytics, allowing users to anticipate potential issues before they arise, thereby enhancing overall operational efficiency. Furthermore, as industries continue to embrace Industry 4.0, the connectivity and data-sharing potential of these devices is set to play a crucial role in streamlining production workflows.

Conclusion

Digital measurement projectors symbolize a significant leap in the quest for precision and efficiency in manufacturing and design. The factories dedicated to their production are at the forefront of this innovation, driving advancements that meet the evolving needs of industries worldwide. As technology progresses, the capabilities of these measurement devices will continue to expand, solidifying their role as essential tools in ensuring quality and precision in modern production environments.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy