Buying Guide for Tensile Testing Equipment and Its Importance in Quality Control

Understanding the Importance of Purchasing a Tensile Tester

In the realm of material science and engineering, the importance of tensile testing cannot be overemphasized. Tensile testing is a fundamental procedure used to assess the mechanical properties of materials, especially metals, polymers, and composites. This method evaluates how materials respond to forces that pull them apart, providing crucial data that can influence the quality and application of products across various industries. Consequently, purchasing a tensile tester becomes a pivotal investment for laboratories, manufacturing facilities, and research institutions.

What is a Tensile Tester?

A tensile tester, also known as a universal testing machine (UTM), is a device that performs tensile tests on materials. It measures the force required to stretch or pull a material to its breaking point. The machine typically consists of a frame, a loading mechanism, and a data acquisition system. During a tensile test, the specimen is placed between two grips in the machine, where it is gradually pulled until it fractures. The results are recorded in terms of stress and strain, which are crucial for determining the material's strength, ductility, and other mechanical properties.

Key Considerations When Purchasing a Tensile Tester

1. Purpose and Application Before making a purchase, it’s essential to define the primary purpose of the tensile tester. Different industries have varied requirements; for instance, the aerospace sector might need to test advanced composite materials, while the automotive industry may focus on metal parts. Understanding the specific applications will guide the selection of the appropriate model.

2. Load Capacity The maximum load the tensile tester can handle is a critical specification. It’s important to choose a machine that can accommodate the highest expected tensile strength of the materials being tested. Oversized testing machines may offer more versatility, but they can also be more expensive and consume more space.

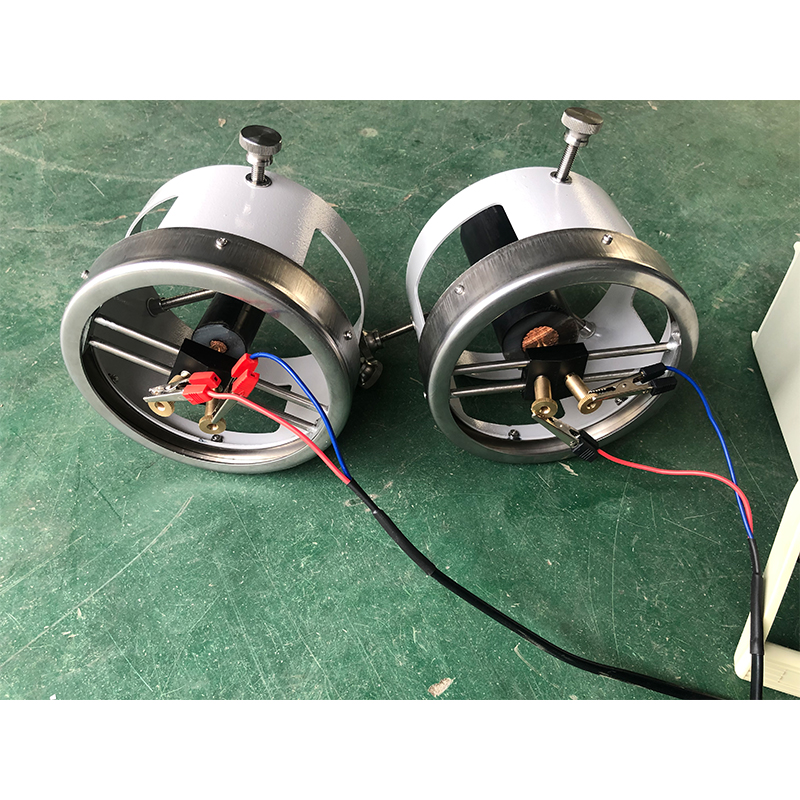

purchasing tensile tester

3. Testing Speed The rate at which the tensile test is conducted can affect the results. Some materials behave differently under varying strain rates. Therefore, it's crucial to select a machine that allows for adjustable testing speeds to simulate real-life conditions accurately.

4. Data Acquisition and Software Modern tensile testers come equipped with sophisticated software that simplifies data collection and analysis. When purchasing, look for systems that provide detailed reports, graphical data representation, and compliance with international testing standards. User-friendly interfaces can significantly enhance the usability of the equipment.

5. Calibration and Maintenance Regular calibration is essential to ensure the accuracy and reliability of the tensile tester. When purchasing, consider the calibration requirements and the availability of support services. A machine that is easy to maintain can save time and costs in the long run.

6. Budget The price of tensile testers can vary widely based on features, capabilities, and brand reputation. It is vital to set a budget, but also to weigh the cost against the functionality and durability of the machine. Investing in a high-quality tensile tester can yield long-term benefits through accurate data and reduced downtime.

Conclusion

Investing in a tensile tester is an essential step for any organization involved in material testing and quality assurance. The insights gained from tensile tests are invaluable for ensuring that materials meet industry standards and perform satisfactorily in their intended applications. By understanding the various factors that influence the purchasing decision, including purpose, load capacity, testing speed, software capabilities, maintenance, and budget, organizations can make informed choices that will support their objectives and propel them toward success.

Ultimately, a well-chosen tensile tester not only enhances the reliability of material testing but also contributes to innovation and safety across numerous industries. Whether you are a small laboratory or a large manufacturing entity, the right tensile tester is a vital tool that can lead to improved product performance and customer satisfaction.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy